Cross docking streamlines supply chains by transferring goods directly from inbound to outbound transportation, minimizing storage time and reducing handling costs. Transloading involves transferring cargo between different transportation modes, often requiring temporary storage and additional handling. Explore the key differences between cross docking and transloading for optimized logistics strategies.

Why it is important

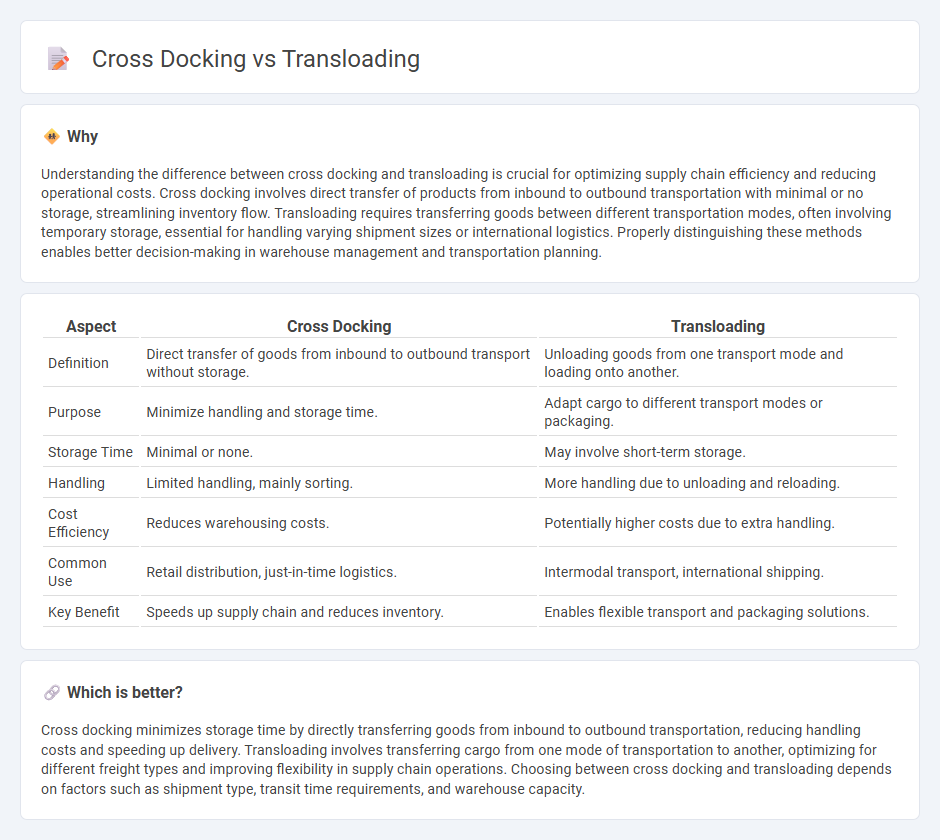

Understanding the difference between cross docking and transloading is crucial for optimizing supply chain efficiency and reducing operational costs. Cross docking involves direct transfer of products from inbound to outbound transportation with minimal or no storage, streamlining inventory flow. Transloading requires transferring goods between different transportation modes, often involving temporary storage, essential for handling varying shipment sizes or international logistics. Properly distinguishing these methods enables better decision-making in warehouse management and transportation planning.

Comparison Table

| Aspect | Cross Docking | Transloading |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound transport without storage. | Unloading goods from one transport mode and loading onto another. |

| Purpose | Minimize handling and storage time. | Adapt cargo to different transport modes or packaging. |

| Storage Time | Minimal or none. | May involve short-term storage. |

| Handling | Limited handling, mainly sorting. | More handling due to unloading and reloading. |

| Cost Efficiency | Reduces warehousing costs. | Potentially higher costs due to extra handling. |

| Common Use | Retail distribution, just-in-time logistics. | Intermodal transport, international shipping. |

| Key Benefit | Speeds up supply chain and reduces inventory. | Enables flexible transport and packaging solutions. |

Which is better?

Cross docking minimizes storage time by directly transferring goods from inbound to outbound transportation, reducing handling costs and speeding up delivery. Transloading involves transferring cargo from one mode of transportation to another, optimizing for different freight types and improving flexibility in supply chain operations. Choosing between cross docking and transloading depends on factors such as shipment type, transit time requirements, and warehouse capacity.

Connection

Cross docking and transloading are interconnected logistics processes that streamline supply chain operations by minimizing storage time and facilitating efficient cargo transfer. Cross docking focuses on directly transferring goods from inbound to outbound transportation with minimal handling, while transloading involves moving freight between different modes of transport, such as from rail to truck. Both methods reduce inventory holding costs and accelerate delivery times by optimizing freight movement within distribution networks.

Key Terms

Transfer Point

Transfer points play a critical role in both transloading and cross docking operations by facilitating efficient movement of goods between vehicles. Transloading involves unloading cargo from one mode of transport and reloading it onto another, often requiring temporary storage or repackaging at transfer points. Cross docking focuses on immediate transfer and sorting of goods with minimal storage time, reducing handling costs and delivery times at the transfer point; explore the nuances of these transfer logistics to optimize your supply chain strategy.

Storage Duration

Transloading involves transferring goods between different transportation modes with temporary storage, often lasting several hours to days to accommodate inspections or sorting. Cross docking minimizes storage time by directly transferring incoming shipments to outbound transportation, typically within a few hours, enhancing rapid distribution efficiency. Explore deeper insights on storage duration impacts in logistics to optimize your supply chain strategy.

Handling Method

Transloading involves transferring goods between different transportation modes, such as from a ship to a truck, requiring unloading and reloading, which allows for customization and inspection during handling. Cross docking minimizes storage time by directly transferring products from inbound to outbound transportation without long-term storage or repackaging, optimizing speed and reducing handling costs. Explore more to understand how these handling methods impact supply chain efficiency.

Source and External Links

What Is Transloading? Meaning, Services & Facility Guide - Transloading is the process of transferring cargo from one vehicle or container to another during shipment to optimize cost and speed, often involving moving freight between different transportation modes like ship, train, and truck to use the most efficient leg for each part of the journey.

Transloading - Wikipedia - Transloading, also known as cross-docking, is transferring a shipment from one transportation mode to another during a trip that requires multiple transport methods, such as combining truck, rail, or air, often involving specialized facilities to minimize handling and risk of damage.

Transloading in Logistics: Everything You Need to Know - Transloading moves goods between transport modes at dedicated facilities equipped for unloading, sorting, consolidating, and reloading cargo, allowing improved flexibility, cost-efficiency, and adaptation to different shipment sizes and transport methods.

dowidth.com

dowidth.com