Micro-fulfillment centers are compact, technology-driven facilities designed to accelerate order processing near urban areas, improving last-mile delivery efficiency and reducing fulfillment times. Satellite warehouses are smaller storage locations strategically positioned to support main distribution centers by holding inventory closer to customers, thus enhancing stock availability and cost-effectiveness. Explore the differences and strategic benefits of micro-fulfillment centers versus satellite warehouses to optimize your logistics network.

Why it is important

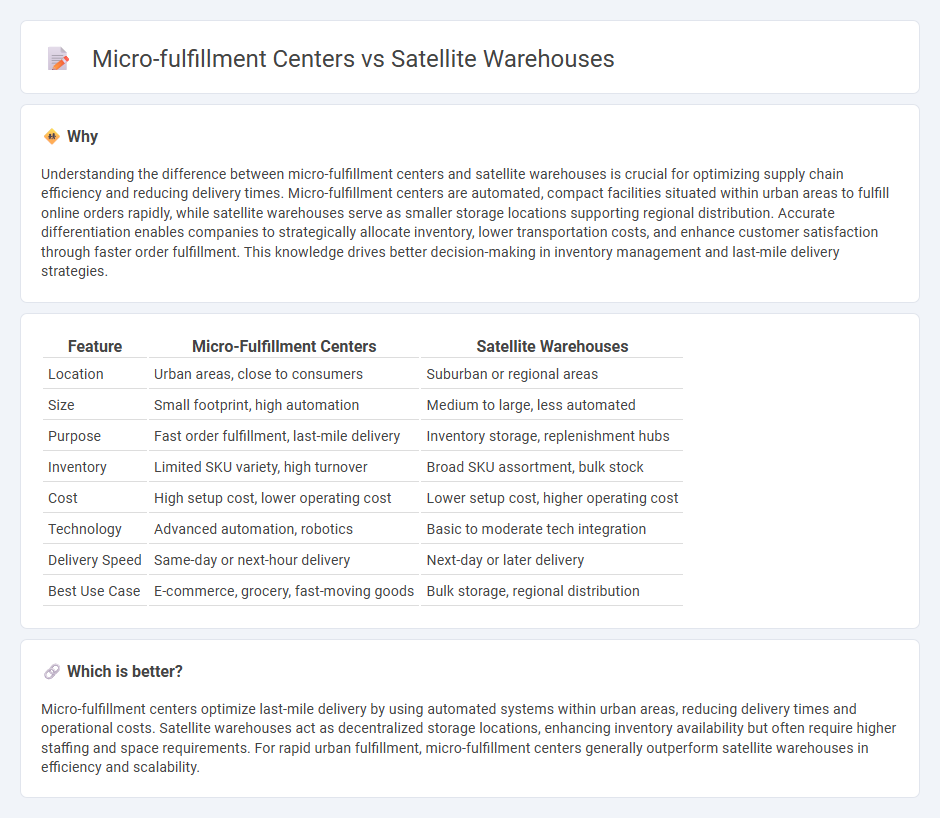

Understanding the difference between micro-fulfillment centers and satellite warehouses is crucial for optimizing supply chain efficiency and reducing delivery times. Micro-fulfillment centers are automated, compact facilities situated within urban areas to fulfill online orders rapidly, while satellite warehouses serve as smaller storage locations supporting regional distribution. Accurate differentiation enables companies to strategically allocate inventory, lower transportation costs, and enhance customer satisfaction through faster order fulfillment. This knowledge drives better decision-making in inventory management and last-mile delivery strategies.

Comparison Table

| Feature | Micro-Fulfillment Centers | Satellite Warehouses |

|---|---|---|

| Location | Urban areas, close to consumers | Suburban or regional areas |

| Size | Small footprint, high automation | Medium to large, less automated |

| Purpose | Fast order fulfillment, last-mile delivery | Inventory storage, replenishment hubs |

| Inventory | Limited SKU variety, high turnover | Broad SKU assortment, bulk stock |

| Cost | High setup cost, lower operating cost | Lower setup cost, higher operating cost |

| Technology | Advanced automation, robotics | Basic to moderate tech integration |

| Delivery Speed | Same-day or next-hour delivery | Next-day or later delivery |

| Best Use Case | E-commerce, grocery, fast-moving goods | Bulk storage, regional distribution |

Which is better?

Micro-fulfillment centers optimize last-mile delivery by using automated systems within urban areas, reducing delivery times and operational costs. Satellite warehouses act as decentralized storage locations, enhancing inventory availability but often require higher staffing and space requirements. For rapid urban fulfillment, micro-fulfillment centers generally outperform satellite warehouses in efficiency and scalability.

Connection

Micro-fulfillment centers and satellite warehouses enhance logistics efficiency by enabling faster order processing and reducing last-mile delivery distances. These facilities leverage advanced automation and real-time inventory management to synchronize stock levels and optimize distribution routes. Integrating micro-fulfillment centers with satellite warehouses supports scalable supply chains and reduces transportation costs, improving overall customer satisfaction.

Key Terms

Inventory Proximity

Satellite warehouses store bulk inventory close to key markets, enabling faster replenishment and reducing stockouts. Micro-fulfillment centers operate within urban areas, focusing on last-mile delivery speed by holding high-demand, ready-to-ship items in smaller quantities. Explore how inventory proximity strategies impact supply chain efficiency and customer satisfaction.

Order Fulfillment Speed

Satellite warehouses strategically positioned near urban areas reduce delivery times by storing inventory closer to customers, enhancing order fulfillment speed for e-commerce businesses. Micro-fulfillment centers leverage automation and robotics within compact spaces to accelerate picking and packing processes, enabling rapid same-day or next-day deliveries. Discover more about how these solutions transform order fulfillment efficiency in modern supply chains.

Facility Size

Satellite warehouses typically range from 10,000 to 50,000 square feet, designed to extend inventory storage closer to customers, improving last-mile delivery efficiency in suburban or rural areas. Micro-fulfillment centers (MFCs) are significantly smaller, often between 1,000 and 10,000 square feet, and utilize advanced automation within dense urban locations to accelerate order fulfillment in high-demand zones. Explore detailed comparisons and strategic implications of these facility sizes to optimize your supply chain network.

Source and External Links

Satellite warehouses - Glossar - Satellite warehouses are a type of compact warehouse where pallets are stored one behind the other on rails, moved by a satellite unit that automates storage and retrieval operations, patented by Westfalia Logistics Solutions Europe GmbH & Co. KG.

Operation of a semi-automatic warehouse with satellite ... - Satellite warehouses use a satellite carriage system to move loads within storage channels, enhancing space utilization, reducing forklift entry, lowering errors, and optimizing warehouse operation efficiency.

Satellite Depot - Satellite depots are mini-warehouses located near end consumers to reduce delivery lead times, improve localized service, and complement centralized warehouses for better distribution efficiency.

dowidth.com

dowidth.com