Middle mile automation enhances efficiency by using robotics and AI to streamline transportation between warehouses and distribution centers, reducing transit times and operational costs. Supply chain visibility leverages real-time data tracking and analytics to monitor goods throughout the entire supply chain, improving decision-making and responsiveness. Explore how integrating middle mile automation with advanced supply chain visibility solutions can transform your logistics operations.

Why it is important

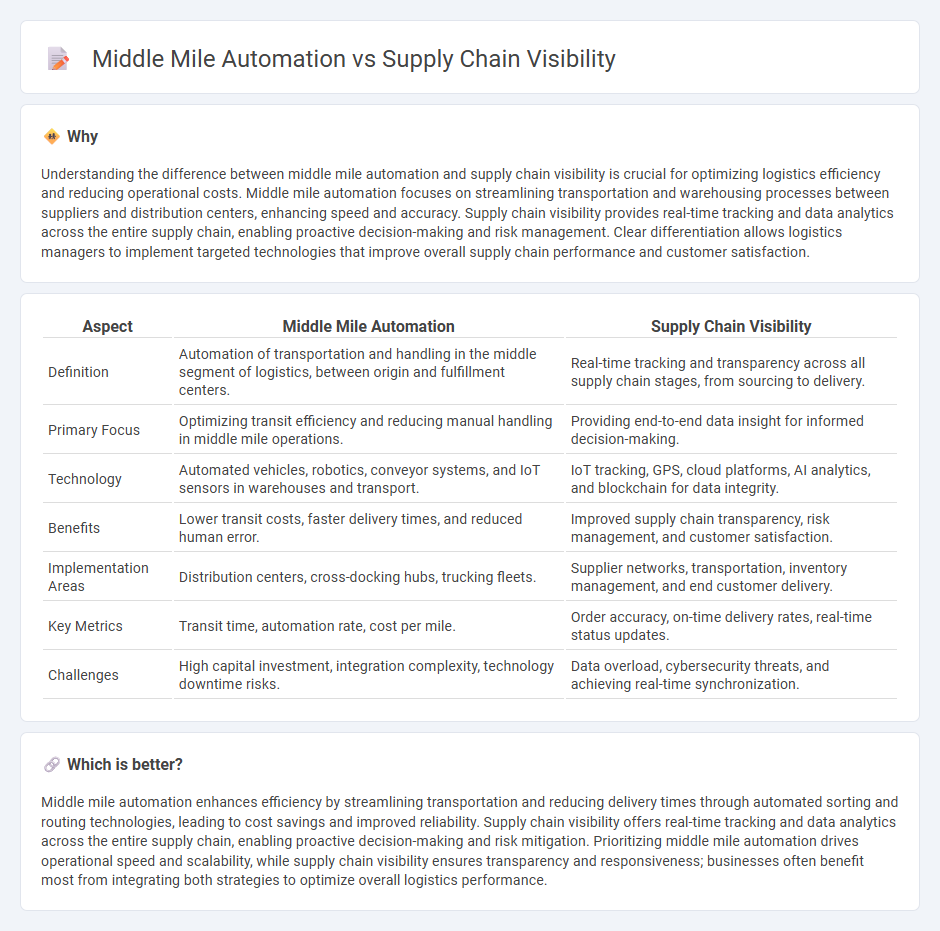

Understanding the difference between middle mile automation and supply chain visibility is crucial for optimizing logistics efficiency and reducing operational costs. Middle mile automation focuses on streamlining transportation and warehousing processes between suppliers and distribution centers, enhancing speed and accuracy. Supply chain visibility provides real-time tracking and data analytics across the entire supply chain, enabling proactive decision-making and risk management. Clear differentiation allows logistics managers to implement targeted technologies that improve overall supply chain performance and customer satisfaction.

Comparison Table

| Aspect | Middle Mile Automation | Supply Chain Visibility |

|---|---|---|

| Definition | Automation of transportation and handling in the middle segment of logistics, between origin and fulfillment centers. | Real-time tracking and transparency across all supply chain stages, from sourcing to delivery. |

| Primary Focus | Optimizing transit efficiency and reducing manual handling in middle mile operations. | Providing end-to-end data insight for informed decision-making. |

| Technology | Automated vehicles, robotics, conveyor systems, and IoT sensors in warehouses and transport. | IoT tracking, GPS, cloud platforms, AI analytics, and blockchain for data integrity. |

| Benefits | Lower transit costs, faster delivery times, and reduced human error. | Improved supply chain transparency, risk management, and customer satisfaction. |

| Implementation Areas | Distribution centers, cross-docking hubs, trucking fleets. | Supplier networks, transportation, inventory management, and end customer delivery. |

| Key Metrics | Transit time, automation rate, cost per mile. | Order accuracy, on-time delivery rates, real-time status updates. |

| Challenges | High capital investment, integration complexity, technology downtime risks. | Data overload, cybersecurity threats, and achieving real-time synchronization. |

Which is better?

Middle mile automation enhances efficiency by streamlining transportation and reducing delivery times through automated sorting and routing technologies, leading to cost savings and improved reliability. Supply chain visibility offers real-time tracking and data analytics across the entire supply chain, enabling proactive decision-making and risk mitigation. Prioritizing middle mile automation drives operational speed and scalability, while supply chain visibility ensures transparency and responsiveness; businesses often benefit most from integrating both strategies to optimize overall logistics performance.

Connection

Middle mile automation enhances supply chain visibility by integrating real-time data from inventory management, transportation tracking, and warehouse operations, enabling precise monitoring of goods in transit. The synchronization of automated systems with advanced analytics platforms provides actionable insights, reducing delays and optimizing route efficiency. Improved visibility through automation supports proactive decision-making, minimizing disruptions and ensuring a seamless flow within the logistics network.

Key Terms

**Supply Chain Visibility:**

Supply chain visibility enhances real-time tracking of goods, inventory levels, and shipment status across multiple touchpoints, enabling proactive issue resolution and improved decision-making. It integrates data from suppliers, logistics providers, and warehouses to create a transparent, end-to-end view of the supply chain. Discover how advanced supply chain visibility solutions can drive operational efficiency and customer satisfaction.

Real-time Tracking

Real-time tracking enhances supply chain visibility by providing continuous updates on shipment locations and status, enabling proactive decision-making and reducing delays. Middle mile automation leverages this data to streamline transportation efficiency through automated routing, load optimization, and checkpoint monitoring. Explore how integrating real-time tracking with middle mile automation drives operational excellence and cost savings.

Data Integration

Supply chain visibility enhances operational efficiency by providing real-time data integration across procurement, warehousing, and transportation, ensuring seamless end-to-end tracking. Middle mile automation leverages data integration to synchronize inventory management, route optimization, and fleet coordination, reducing delays and operational costs. Explore advanced data integration strategies to optimize both supply chain visibility and middle mile automation for superior logistics performance.

Source and External Links

What is Supply Chain Visibility? Meaning and Definition - GEP - Supply chain visibility is the ability to view or track inventory as it moves through the supply chain in real time, enabling enterprises to optimize inventory, improve coordination, mitigate risk, and enhance efficiency using AI-driven platforms for end-to-end transparency.

What is Supply Chain Visibility? - Tibco - Supply chain visibility tracks a product from raw materials through manufacturing to customers, requiring unified and transparent access to data from every department to improve efficiency and customer satisfaction.

What Is Supply Chain Visibility (SCV)? Definition & Examples - Supply chain visibility provides detailed tracking of components, products, and supplier information throughout the supply chain to alert companies immediately about issues, enabling them to respond quickly and maintain transparency with customers.

dowidth.com

dowidth.com