Supply chain control towers provide centralized visibility and real-time monitoring across the entire supply chain, enabling proactive decision-making and risk management. Supplier relationship management focuses on strategic collaboration, performance evaluation, and communication improvement with individual suppliers to ensure quality and reliability. Explore deeper insights to understand how these approaches complement each other in optimizing logistics operations.

Why it is important

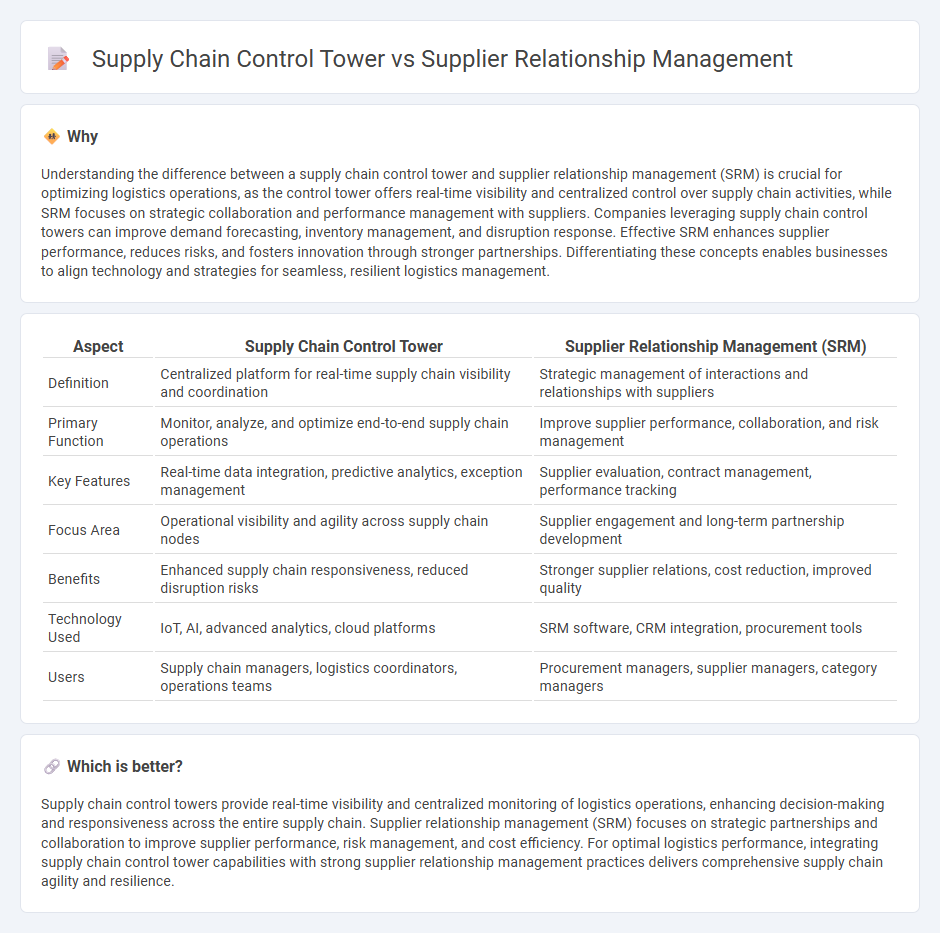

Understanding the difference between a supply chain control tower and supplier relationship management (SRM) is crucial for optimizing logistics operations, as the control tower offers real-time visibility and centralized control over supply chain activities, while SRM focuses on strategic collaboration and performance management with suppliers. Companies leveraging supply chain control towers can improve demand forecasting, inventory management, and disruption response. Effective SRM enhances supplier performance, reduces risks, and fosters innovation through stronger partnerships. Differentiating these concepts enables businesses to align technology and strategies for seamless, resilient logistics management.

Comparison Table

| Aspect | Supply Chain Control Tower | Supplier Relationship Management (SRM) |

|---|---|---|

| Definition | Centralized platform for real-time supply chain visibility and coordination | Strategic management of interactions and relationships with suppliers |

| Primary Function | Monitor, analyze, and optimize end-to-end supply chain operations | Improve supplier performance, collaboration, and risk management |

| Key Features | Real-time data integration, predictive analytics, exception management | Supplier evaluation, contract management, performance tracking |

| Focus Area | Operational visibility and agility across supply chain nodes | Supplier engagement and long-term partnership development |

| Benefits | Enhanced supply chain responsiveness, reduced disruption risks | Stronger supplier relations, cost reduction, improved quality |

| Technology Used | IoT, AI, advanced analytics, cloud platforms | SRM software, CRM integration, procurement tools |

| Users | Supply chain managers, logistics coordinators, operations teams | Procurement managers, supplier managers, category managers |

Which is better?

Supply chain control towers provide real-time visibility and centralized monitoring of logistics operations, enhancing decision-making and responsiveness across the entire supply chain. Supplier relationship management (SRM) focuses on strategic partnerships and collaboration to improve supplier performance, risk management, and cost efficiency. For optimal logistics performance, integrating supply chain control tower capabilities with strong supplier relationship management practices delivers comprehensive supply chain agility and resilience.

Connection

Supply chain control towers enhance supplier relationship management by providing real-time visibility into supplier performance, inventory levels, and order status, enabling proactive decision-making. This centralized data integration improves collaboration, risk mitigation, and responsiveness across the supply chain. Effective control towers streamline communication and foster stronger supplier partnerships through data-driven insights.

Key Terms

**Supplier Relationship Management:**

Supplier Relationship Management (SRM) enhances collaboration by strategically managing interactions with suppliers to improve quality, reduce costs, and mitigate risks within the supply chain. It enables businesses to foster long-term partnerships, optimize supplier performance, and ensure timely delivery of materials. Explore how integrating advanced SRM practices can transform your procurement strategy and drive operational excellence.

Supplier Collaboration

Supplier Relationship Management (SRM) centers on fostering strong collaborations and strategic partnerships with suppliers to enhance communication, trust, and performance in the procurement process. Supply Chain Control Tower integrates real-time data monitoring across the supply network, enabling proactive issue resolution and end-to-end visibility, but its focus on collaboration is indirect. Explore how leveraging both SRM and Control Tower technologies can transform supplier collaboration for operational excellence.

Contract Management

Supplier relationship management (SRM) centers on fostering strong partnerships, emphasizing contract negotiation, compliance, and performance tracking to ensure value and risk mitigation. In contrast, supply chain control towers offer real-time visibility and data-driven insights across the supply chain, aiding in proactive decision-making and dynamic issue resolution but with less focus on detailed contract governance. Explore our detailed comparison to understand how each approach can optimize contract management in your supply networks.

Source and External Links

What is Supplier Relationship Management in Procurement? - Supplier relationship management (SRM) is a strategic, continuous process to collaborate with suppliers through supplier identification, segmentation, defining KPIs, strategy development, engagement, performance monitoring, and continuous improvement to maximize value and optimize supplier relationships.

Supplier relationship management - SRM is an enterprise-wide systematic assessment and coordinated management of suppliers throughout the relationship lifecycle to foster mutually beneficial, innovative partnerships that offer competitive advantage and reduce risks.

What Is Supplier Relationship Management (SRM)? - SRM involves classifying suppliers, strategic planning, collaboration, execution, and ongoing learning to improve supply chain performance, balancing both reactive and strategic management approaches.

dowidth.com

dowidth.com