Supply chain control towers provide centralized visibility and real-time data analytics to monitor and manage the entire supply chain network, enabling proactive decision-making and disruption mitigation. Inventory management focuses on tracking stock levels, optimizing reorder points, and ensuring product availability to meet customer demand while minimizing holding costs. Explore how integrating supply chain control towers with inventory management enhances operational efficiency and responsiveness.

Why it is important

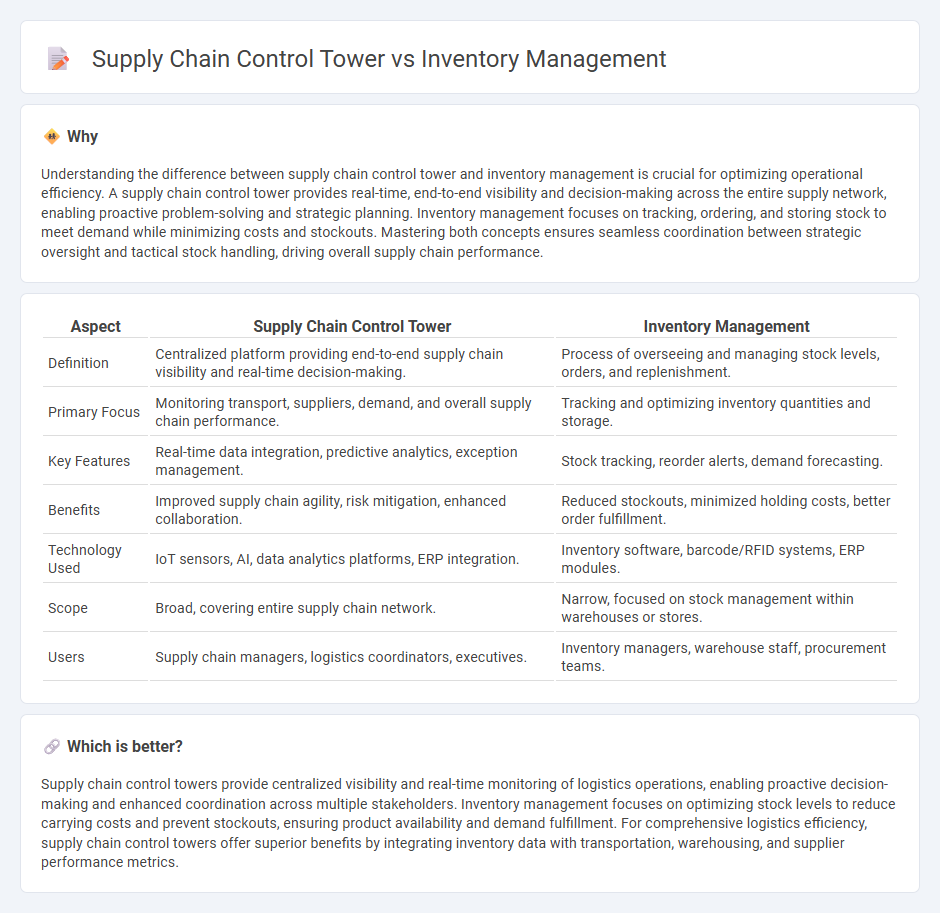

Understanding the difference between supply chain control tower and inventory management is crucial for optimizing operational efficiency. A supply chain control tower provides real-time, end-to-end visibility and decision-making across the entire supply network, enabling proactive problem-solving and strategic planning. Inventory management focuses on tracking, ordering, and storing stock to meet demand while minimizing costs and stockouts. Mastering both concepts ensures seamless coordination between strategic oversight and tactical stock handling, driving overall supply chain performance.

Comparison Table

| Aspect | Supply Chain Control Tower | Inventory Management |

|---|---|---|

| Definition | Centralized platform providing end-to-end supply chain visibility and real-time decision-making. | Process of overseeing and managing stock levels, orders, and replenishment. |

| Primary Focus | Monitoring transport, suppliers, demand, and overall supply chain performance. | Tracking and optimizing inventory quantities and storage. |

| Key Features | Real-time data integration, predictive analytics, exception management. | Stock tracking, reorder alerts, demand forecasting. |

| Benefits | Improved supply chain agility, risk mitigation, enhanced collaboration. | Reduced stockouts, minimized holding costs, better order fulfillment. |

| Technology Used | IoT sensors, AI, data analytics platforms, ERP integration. | Inventory software, barcode/RFID systems, ERP modules. |

| Scope | Broad, covering entire supply chain network. | Narrow, focused on stock management within warehouses or stores. |

| Users | Supply chain managers, logistics coordinators, executives. | Inventory managers, warehouse staff, procurement teams. |

Which is better?

Supply chain control towers provide centralized visibility and real-time monitoring of logistics operations, enabling proactive decision-making and enhanced coordination across multiple stakeholders. Inventory management focuses on optimizing stock levels to reduce carrying costs and prevent stockouts, ensuring product availability and demand fulfillment. For comprehensive logistics efficiency, supply chain control towers offer superior benefits by integrating inventory data with transportation, warehousing, and supplier performance metrics.

Connection

Supply chain control towers enhance inventory management by providing real-time visibility across distribution channels, enabling accurate demand forecasting and dynamic stock replenishment. Centralized data analytics within the control tower optimize inventory levels, reduce carrying costs, and prevent stockouts or overstock situations. Integration of these systems ensures seamless coordination between procurement, warehousing, and order fulfillment for efficient supply chain operations.

Key Terms

**Inventory Management:**

Inventory management optimizes stock levels through demand forecasting, real-time tracking, and replenishment strategies to reduce holding costs and prevent stockouts. It involves granular control over warehousing, order processing, and SKU categorization to enhance operational efficiency. Explore deeper insights into how inventory management drives supply chain performance and profitability.

Stock Keeping Unit (SKU)

Inventory management focuses on tracking and optimizing Stock Keeping Unit (SKU) levels within warehouses to reduce holding costs and prevent stockouts. Supply chain control towers provide real-time visibility across multiple facilities, enabling proactive response to SKU demand fluctuations, transportation delays, and order fulfillment challenges. Explore how integrating SKU-centric inventory management with control tower capabilities can enhance overall supply chain efficiency.

Reorder Point

Inventory management centers on determining the optimal Reorder Point (ROP) to maintain stock levels by analyzing demand patterns, lead times, and safety stock, ensuring timely replenishment and reducing stockouts. Supply chain control towers provide a holistic, real-time visibility platform that integrates data across the supply chain to monitor inventory status, demand fluctuations, and supplier performance, enabling proactive adjustment of ROP settings for enhanced responsiveness. Explore how leveraging advanced analytics in control towers can transform your inventory management strategy by optimizing Reorder Points and improving supply chain agility.

Source and External Links

What Is Inventory Management? Benefits, Types, & Techniques - Inventory management is the process of tracking and controlling goods flow including demand planning, ordering, delivery, tracking, sales, review, and replenishment to optimize stock levels and supply chain efficiency.

Inventory Management: How it Works and Tools (2025) - Shopify - Inventory management involves overseeing the flow of goods using techniques such as economic order quantity, demand planning, inventory counts, and technology like barcodes or RFID to improve ordering and cash flow.

Inventory Management Guide + Methods & Examples - Extensiv - Inventory management systems include manual methods like spreadsheets and automated solutions with technologies like RFID and ERP software to track stock, manage orders, and optimize multichannel inventory across sales platforms.

dowidth.com

dowidth.com