Dropshipping eliminates the need for inventory storage by directly shipping products from suppliers to customers, enhancing cash flow and reducing overhead costs. Lean logistics focuses on minimizing waste within the supply chain, streamlining processes to improve efficiency and reduce delivery times. Explore the key differences between dropshipping and lean logistics to determine the best strategy for your business.

Why it is important

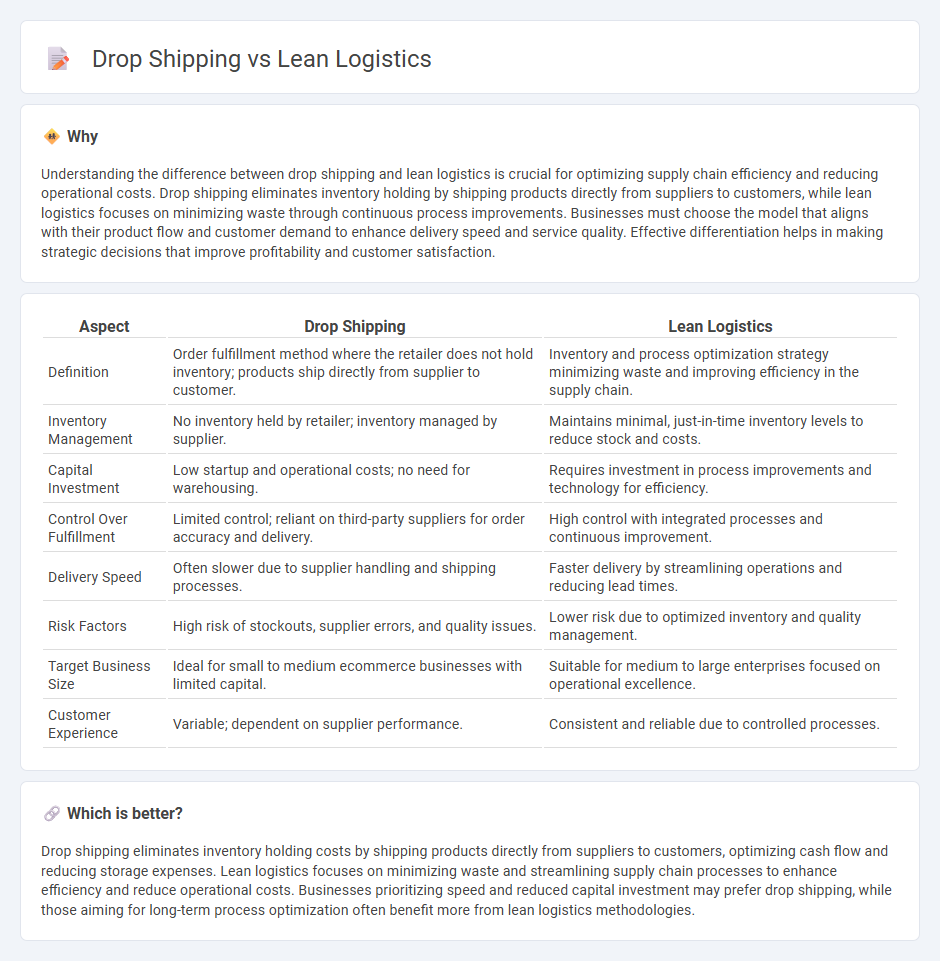

Understanding the difference between drop shipping and lean logistics is crucial for optimizing supply chain efficiency and reducing operational costs. Drop shipping eliminates inventory holding by shipping products directly from suppliers to customers, while lean logistics focuses on minimizing waste through continuous process improvements. Businesses must choose the model that aligns with their product flow and customer demand to enhance delivery speed and service quality. Effective differentiation helps in making strategic decisions that improve profitability and customer satisfaction.

Comparison Table

| Aspect | Drop Shipping | Lean Logistics |

|---|---|---|

| Definition | Order fulfillment method where the retailer does not hold inventory; products ship directly from supplier to customer. | Inventory and process optimization strategy minimizing waste and improving efficiency in the supply chain. |

| Inventory Management | No inventory held by retailer; inventory managed by supplier. | Maintains minimal, just-in-time inventory levels to reduce stock and costs. |

| Capital Investment | Low startup and operational costs; no need for warehousing. | Requires investment in process improvements and technology for efficiency. |

| Control Over Fulfillment | Limited control; reliant on third-party suppliers for order accuracy and delivery. | High control with integrated processes and continuous improvement. |

| Delivery Speed | Often slower due to supplier handling and shipping processes. | Faster delivery by streamlining operations and reducing lead times. |

| Risk Factors | High risk of stockouts, supplier errors, and quality issues. | Lower risk due to optimized inventory and quality management. |

| Target Business Size | Ideal for small to medium ecommerce businesses with limited capital. | Suitable for medium to large enterprises focused on operational excellence. |

| Customer Experience | Variable; dependent on supplier performance. | Consistent and reliable due to controlled processes. |

Which is better?

Drop shipping eliminates inventory holding costs by shipping products directly from suppliers to customers, optimizing cash flow and reducing storage expenses. Lean logistics focuses on minimizing waste and streamlining supply chain processes to enhance efficiency and reduce operational costs. Businesses prioritizing speed and reduced capital investment may prefer drop shipping, while those aiming for long-term process optimization often benefit more from lean logistics methodologies.

Connection

Drop shipping and lean logistics are connected through their shared goal of minimizing inventory holding costs and streamlining supply chain operations. Drop shipping eliminates the need for warehousing by shipping products directly from suppliers to customers, while lean logistics focuses on reducing waste and improving efficiency in transportation and distribution processes. Both strategies enhance responsiveness and cost-effectiveness in fulfillment, supporting agile and customer-centric supply chain management.

Key Terms

**Lean Logistics:**

Lean logistics streamlines supply chain processes by minimizing waste, reducing lead times, and enhancing inventory efficiency to achieve cost savings and improved customer satisfaction. It emphasizes continuous improvement, just-in-time delivery, and precise demand forecasting to optimize the flow of goods from supplier to end consumer. Explore how lean logistics can transform your supply chain management for better operational performance and agility.

Waste Reduction

Lean logistics emphasizes minimizing waste by streamlining inventory management, reducing transportation inefficiencies, and eliminating non-value-added activities within the supply chain. Drop shipping reduces waste by bypassing warehousing and inventory holding, directly shipping products from suppliers to customers, thus decreasing overproduction and excess stock. Explore the benefits and limitations of each approach in waste reduction to optimize your supply chain strategy.

Just-in-Time (JIT)

Lean logistics prioritizes Just-in-Time (JIT) inventory management to minimize waste by receiving goods only as they are needed, enhancing operational efficiency and reducing storage costs. Drop shipping bypasses traditional inventory holding, relying on suppliers to directly ship products to customers, which can reduce lead times but may sacrifice some control over inventory accuracy and delivery speed. Explore how integrating JIT principles into both methods can optimize supply chain performance and customer satisfaction.

Source and External Links

Lean Logistics: Streamlining Your Supply Chain for Efficiency and ... - Lean logistics is a management approach focusing on identifying and eliminating waste in supply chains to improve goods flow, reduce costs, and boost efficiency by removing unnecessary processes.

Lean logistics: lean into efficiency - Mecalux.com - Lean logistics aims to reduce logistics costs by trimming non-value-added tasks, doing more with less effort, space, time, and equipment, and shortening order cycle times through tools like value-stream mapping and just-in-time systems.

Lean Logistics: Improving Efficiency in the Supply Chain - Lean logistics optimizes supply chains by cutting wasteful activities and maximizing customer value to prevent bottlenecks, ensure smooth fulfilment, and reduce costs, originating from Lean Thinking methodology.

dowidth.com

dowidth.com