Cold chain logistics focuses on maintaining temperature-sensitive products within strict thermal ranges during transportation and storage, ensuring the integrity of pharmaceuticals, perishable foods, and biologics. Just-in-time logistics emphasizes minimizing inventory by synchronizing supply deliveries directly with production schedules, reducing storage costs and enhancing efficiency. Discover more about how each strategy optimizes supply chain performance and meets specific industry demands.

Why it is important

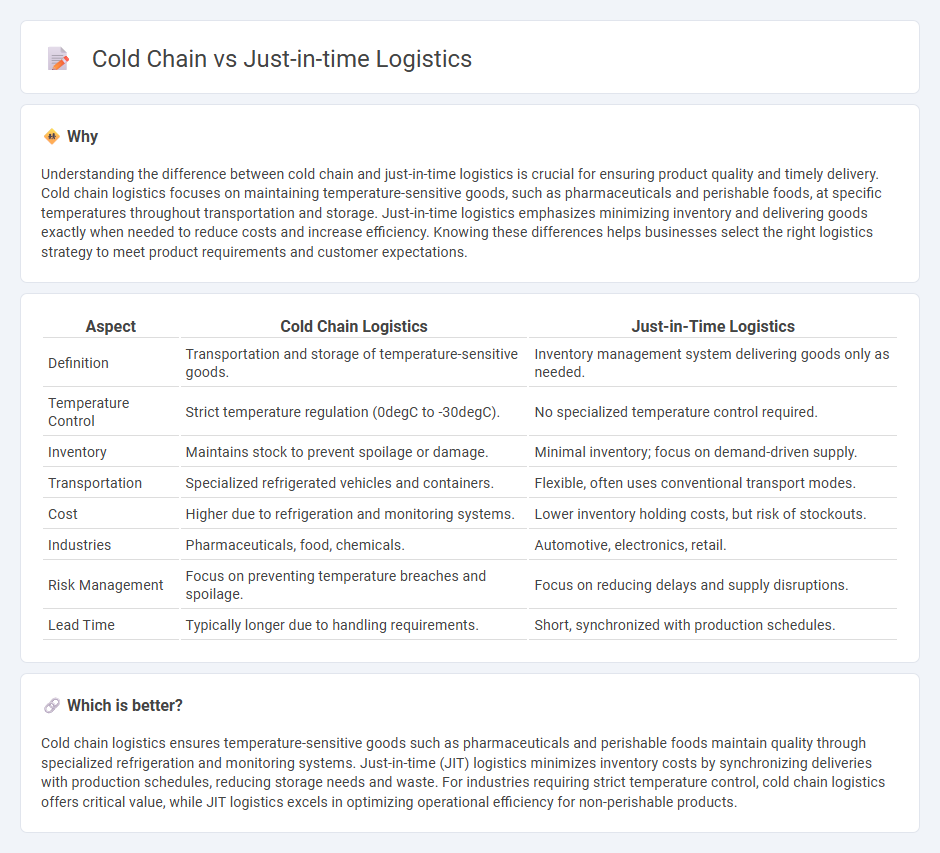

Understanding the difference between cold chain and just-in-time logistics is crucial for ensuring product quality and timely delivery. Cold chain logistics focuses on maintaining temperature-sensitive goods, such as pharmaceuticals and perishable foods, at specific temperatures throughout transportation and storage. Just-in-time logistics emphasizes minimizing inventory and delivering goods exactly when needed to reduce costs and increase efficiency. Knowing these differences helps businesses select the right logistics strategy to meet product requirements and customer expectations.

Comparison Table

| Aspect | Cold Chain Logistics | Just-in-Time Logistics |

|---|---|---|

| Definition | Transportation and storage of temperature-sensitive goods. | Inventory management system delivering goods only as needed. |

| Temperature Control | Strict temperature regulation (0degC to -30degC). | No specialized temperature control required. |

| Inventory | Maintains stock to prevent spoilage or damage. | Minimal inventory; focus on demand-driven supply. |

| Transportation | Specialized refrigerated vehicles and containers. | Flexible, often uses conventional transport modes. |

| Cost | Higher due to refrigeration and monitoring systems. | Lower inventory holding costs, but risk of stockouts. |

| Industries | Pharmaceuticals, food, chemicals. | Automotive, electronics, retail. |

| Risk Management | Focus on preventing temperature breaches and spoilage. | Focus on reducing delays and supply disruptions. |

| Lead Time | Typically longer due to handling requirements. | Short, synchronized with production schedules. |

Which is better?

Cold chain logistics ensures temperature-sensitive goods such as pharmaceuticals and perishable foods maintain quality through specialized refrigeration and monitoring systems. Just-in-time (JIT) logistics minimizes inventory costs by synchronizing deliveries with production schedules, reducing storage needs and waste. For industries requiring strict temperature control, cold chain logistics offers critical value, while JIT logistics excels in optimizing operational efficiency for non-perishable products.

Connection

Cold chain logistics ensures the temperature-controlled storage and transportation of perishable goods, maintaining product quality and safety from origin to delivery. Just-in-time logistics minimizes inventory levels by synchronizing supply chain operations, which requires efficient cold chain management to prevent spoilage during rapid replenishment cycles. Integration of cold chain with just-in-time logistics optimizes freshness and reduces waste in sectors such as pharmaceuticals and food distribution.

Key Terms

Just-in-time logistics:

Just-in-time logistics emphasizes minimizing inventory levels by synchronizing delivery schedules with production demand, reducing storage costs and increasing operational efficiency. This approach relies on precise coordination, real-time data analytics, and agile transportation systems to ensure materials and products arrive exactly when needed, avoiding delays and overstocking. Discover more about how just-in-time logistics transforms supply chain management by optimizing timing and resource allocation.

Lead Time

Just-in-time logistics minimizes lead time by synchronizing inventory deliveries precisely when needed, reducing storage costs and enhancing production efficiency. Cold chain logistics, while also aiming to shorten lead time, prioritizes maintaining temperature-sensitive products within strict thermal conditions throughout transit to preserve quality and safety. Explore detailed strategies to optimize lead time in both just-in-time and cold chain logistics systems.

Inventory Management

Just-in-time logistics minimizes inventory levels by synchronizing supply deliveries with production schedules, reducing storage costs and enhancing cash flow. Cold chain logistics ensures the integrity of temperature-sensitive products through controlled storage and transportation, preventing spoilage and compliance issues. Explore detailed strategies to optimize inventory management in both logistics systems.

Source and External Links

Just-in-Time (JIT) Logistics Strategy - JIT logistics is a strategy delivering goods precisely when needed to reduce inventory costs, improve supply chain efficiency, and eliminate excess stock through coordinated supplier and freight collaboration.

Just-in-Time Logistics & Distribution: Meaning & Examples - JIT logistics synchronizes raw material arrivals with production schedules to minimize inventory and improve cash flow, relying on precise demand forecasting and supply chain collaboration.

What is Just-in-Time (JIT) Logistics? Principles and Benefits - JIT logistics focuses on aligning deliveries with production, enhancing efficiency and minimizing waste through demand forecasting, strong supplier relationships, and inventory management.

dowidth.com

dowidth.com