Container pooling optimizes supply chain efficiency by sharing standardized containers among companies, reducing empty runs and lowering costs. Container pooling can be structured as closed-loop, where containers circulate between predefined partners, or open-loop, allowing broader access and flexibility across multiple users and locations. Explore the benefits and practical applications of container pooling models to enhance your logistics strategy.

Why it is important

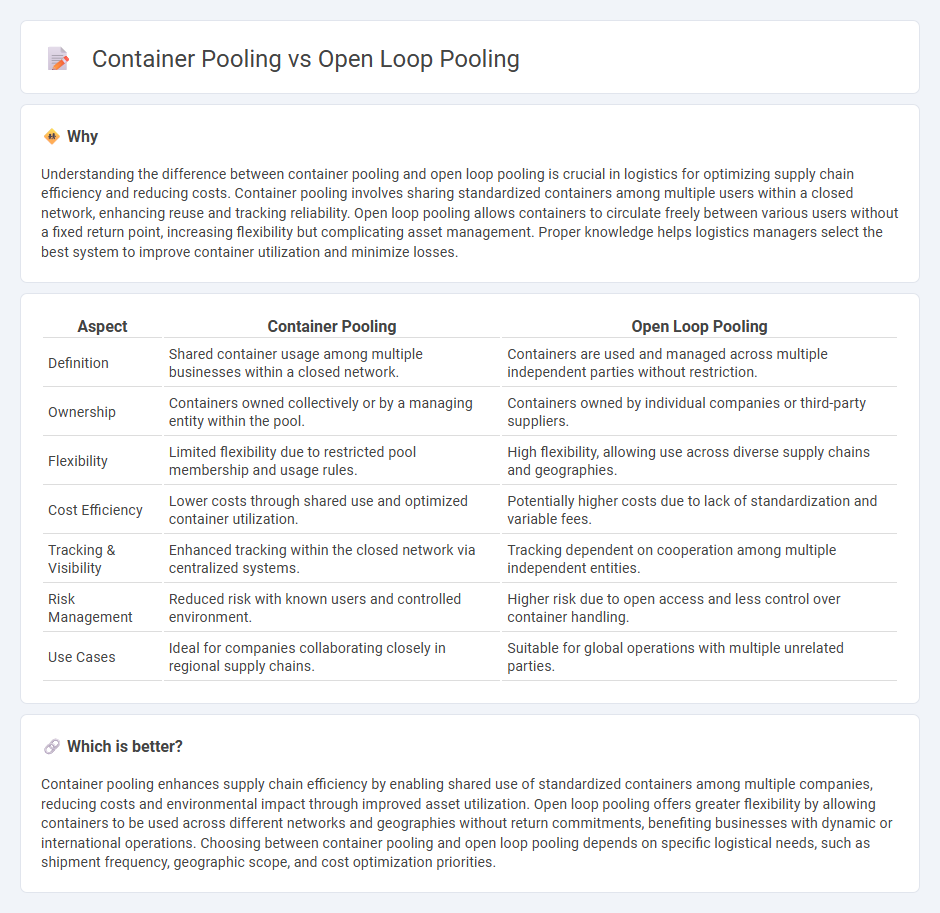

Understanding the difference between container pooling and open loop pooling is crucial in logistics for optimizing supply chain efficiency and reducing costs. Container pooling involves sharing standardized containers among multiple users within a closed network, enhancing reuse and tracking reliability. Open loop pooling allows containers to circulate freely between various users without a fixed return point, increasing flexibility but complicating asset management. Proper knowledge helps logistics managers select the best system to improve container utilization and minimize losses.

Comparison Table

| Aspect | Container Pooling | Open Loop Pooling |

|---|---|---|

| Definition | Shared container usage among multiple businesses within a closed network. | Containers are used and managed across multiple independent parties without restriction. |

| Ownership | Containers owned collectively or by a managing entity within the pool. | Containers owned by individual companies or third-party suppliers. |

| Flexibility | Limited flexibility due to restricted pool membership and usage rules. | High flexibility, allowing use across diverse supply chains and geographies. |

| Cost Efficiency | Lower costs through shared use and optimized container utilization. | Potentially higher costs due to lack of standardization and variable fees. |

| Tracking & Visibility | Enhanced tracking within the closed network via centralized systems. | Tracking dependent on cooperation among multiple independent entities. |

| Risk Management | Reduced risk with known users and controlled environment. | Higher risk due to open access and less control over container handling. |

| Use Cases | Ideal for companies collaborating closely in regional supply chains. | Suitable for global operations with multiple unrelated parties. |

Which is better?

Container pooling enhances supply chain efficiency by enabling shared use of standardized containers among multiple companies, reducing costs and environmental impact through improved asset utilization. Open loop pooling offers greater flexibility by allowing containers to be used across different networks and geographies without return commitments, benefiting businesses with dynamic or international operations. Choosing between container pooling and open loop pooling depends on specific logistical needs, such as shipment frequency, geographic scope, and cost optimization priorities.

Connection

Container pooling and open loop pooling enhance logistics efficiency by maximizing asset utilization and reducing empty container repositioning. Container pooling involves shared use of standardized containers among multiple stakeholders, while open loop pooling expands this concept by allowing containers to circulate broadly across different companies and geographies. Both systems optimize supply chain flexibility, minimizing storage costs and improving sustainability in freight transport.

Key Terms

Asset Ownership

Open loop pooling involves multiple companies sharing assets without a direct ownership transfer, promoting flexibility and cost efficiency in asset utilization. Container pooling, on the other hand, typically features asset ownership retained by a single entity or pool operator, ensuring standardized maintenance and operational control. Explore deeper insights on optimizing asset ownership strategies within supply chain logistics.

Recovery Process

Open loop pooling systems require extensive cleaning and sanitization between uses, as they circulate containers through various, often unrelated users, increasing contamination risk and recovery time. Container pooling relies on closed-loop cycles, where containers are repeatedly used within a controlled network, optimizing recovery efficiency through streamlined inspection, cleaning, and redistribution protocols. Explore the specifics of how these recovery processes impact operational costs and sustainability by learning more about their workflows.

Cost Allocation

Open loop pooling reduces cost allocation complexity by allowing multiple users to share assets without strict tracking, leading to lower administrative expenses. Container pooling allocates costs based on container usage, providing precise cost tracking but increasing billing and management overhead. Explore detailed cost allocation strategies in pooling models to optimize operational efficiency.

Source and External Links

MUSE - Open-loop systems requirements & advantages - GeoERA - Open-loop pooling systems withdraw groundwater from wells to transfer heat to a heat pump and then reinject the water back into the aquifer, offering higher inlet temperatures, efficiency, and lower drilling costs compared to closed-loop systems.

Should You Use an Open or Closed Loop Method? - Open loop methods are more efficient and cost-effective for large-scale pools, utilizing well water systems with lower initial cost compared to closed-loop systems which can have prohibitive installation costs.

Overview of open-loop circulation | Thermo Fisher Scientific - Open-loop circulation involves pumping fluid from a temperature-controlled reservoir open to the atmosphere into another open container, differing from closed-loop systems which maintain a sealed pumping loop and are generally more complex.

dowidth.com

dowidth.com