Last foot delivery focuses on transporting goods directly from the warehouse to the final customer, emphasizing speed and individual order accuracy, often used in e-commerce and urgent shipments. Milk run logistics consolidates multiple deliveries or pickups into a single route to optimize cost and efficiency, especially beneficial in manufacturing and retail supply chains. Explore detailed comparisons to determine the best strategy for your logistics needs.

Why it is important

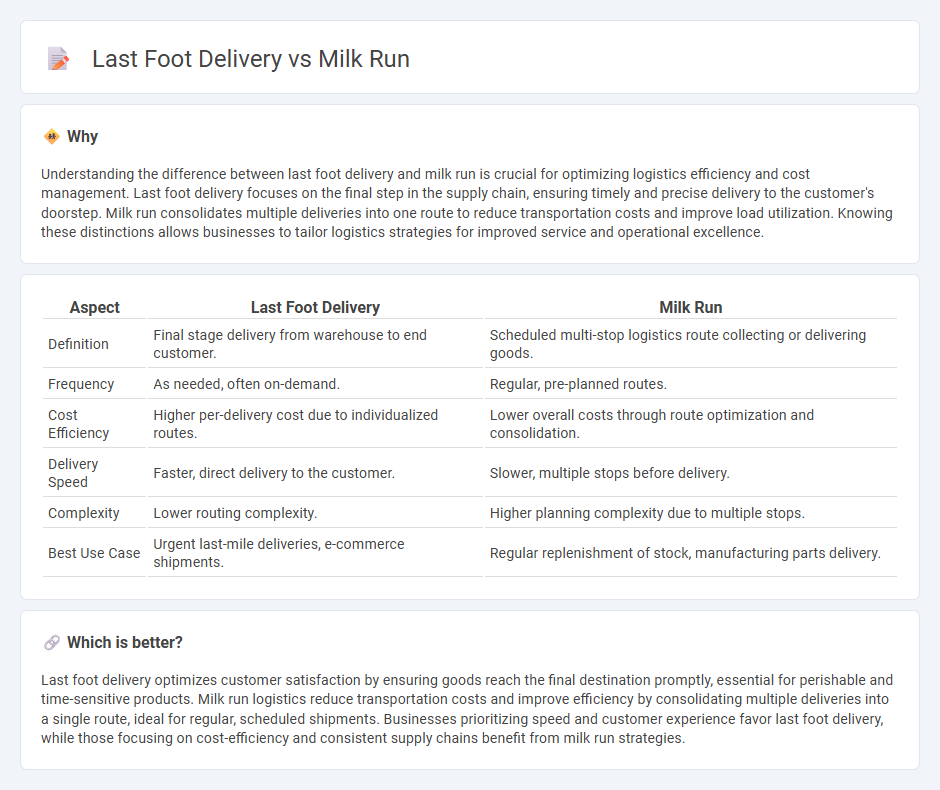

Understanding the difference between last foot delivery and milk run is crucial for optimizing logistics efficiency and cost management. Last foot delivery focuses on the final step in the supply chain, ensuring timely and precise delivery to the customer's doorstep. Milk run consolidates multiple deliveries into one route to reduce transportation costs and improve load utilization. Knowing these distinctions allows businesses to tailor logistics strategies for improved service and operational excellence.

Comparison Table

| Aspect | Last Foot Delivery | Milk Run |

|---|---|---|

| Definition | Final stage delivery from warehouse to end customer. | Scheduled multi-stop logistics route collecting or delivering goods. |

| Frequency | As needed, often on-demand. | Regular, pre-planned routes. |

| Cost Efficiency | Higher per-delivery cost due to individualized routes. | Lower overall costs through route optimization and consolidation. |

| Delivery Speed | Faster, direct delivery to the customer. | Slower, multiple stops before delivery. |

| Complexity | Lower routing complexity. | Higher planning complexity due to multiple stops. |

| Best Use Case | Urgent last-mile deliveries, e-commerce shipments. | Regular replenishment of stock, manufacturing parts delivery. |

Which is better?

Last foot delivery optimizes customer satisfaction by ensuring goods reach the final destination promptly, essential for perishable and time-sensitive products. Milk run logistics reduce transportation costs and improve efficiency by consolidating multiple deliveries into a single route, ideal for regular, scheduled shipments. Businesses prioritizing speed and customer experience favor last foot delivery, while those focusing on cost-efficiency and consistent supply chains benefit from milk run strategies.

Connection

Last foot delivery and milk run logistics are interconnected through their focus on optimizing the final stage of supply chain distribution. Milk run strategies consolidate multiple deliveries into a single route, reducing transportation costs and improving delivery frequency, which directly supports efficient last foot delivery by ensuring timely and cost-effective delivery to end consumers. This synergy enhances overall supply chain responsiveness and sustainability by minimizing vehicle usage and streamlining delivery operations.

Key Terms

Route Optimization

Milk run route optimization consolidates multiple delivery points into a single loop, minimizing transit time and reducing transportation costs by maximizing vehicle load efficiency. Last foot delivery prioritizes optimizing routes for final-mile delivery, focusing on speed and accuracy to enhance customer satisfaction in urban and dense areas. Explore detailed strategies to optimize both milk run and last foot delivery for your logistics operations.

Consolidation

Milk run logistics optimizes consolidation by grouping multiple shipments from various suppliers into one streamlined delivery route, reducing transportation costs and environmental impact. Last foot delivery focuses on the final leg, delivering consolidated goods directly to the customer's doorstep to enhance service efficiency and speed. Explore how strategic consolidation in both methods improves supply chain performance and customer satisfaction.

Drop-off Point

Milk run and last foot delivery differ primarily in drop-off point management, where milk run consolidates multiple shipments to a single drop-off location optimizing route efficiency and reducing transportation costs. In contrast, last foot delivery targets the final customer drop-off, emphasizing speed and precision directly to the end destination. Explore the distinct advantages of these delivery methods to enhance your supply chain strategy and improve customer satisfaction.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - ShipBob - The term "milk run" originates from the dairy industry where one tanker collects milk from multiple farms to deliver to a processing plant, and today in logistics it refers to using one vehicle to pick up goods from various suppliers and transport them in a single shipment to one destination for supply chain efficiency.

What is a milk run in logistics? | Red Stag Fulfillment - A milk run is a recurring, pre-defined route that involves traveling short distances to pick up or deliver items at multiple stops, minimizing costs and ensuring timely inventory replenishment for lean manufacturing and warehouse operations.

What is Milk Run in Logistics? - FlexQube - The milk run method is used within facilities and factories to enable frequent deliveries of materials to multiple assembly areas, reducing overstocking and downtime by optimizing transport routes and timing according to the layout of the production environment.

dowidth.com

dowidth.com