Dynamic route optimization leverages real-time data and advanced algorithms to continually adjust delivery routes, enhancing efficiency and reducing fuel consumption. Milk-run routing consolidates multiple deliveries into a single, pre-planned loop, minimizing transportation costs and improving load utilization. Explore the advantages and applications of both methods to optimize your logistics operations.

Why it is important

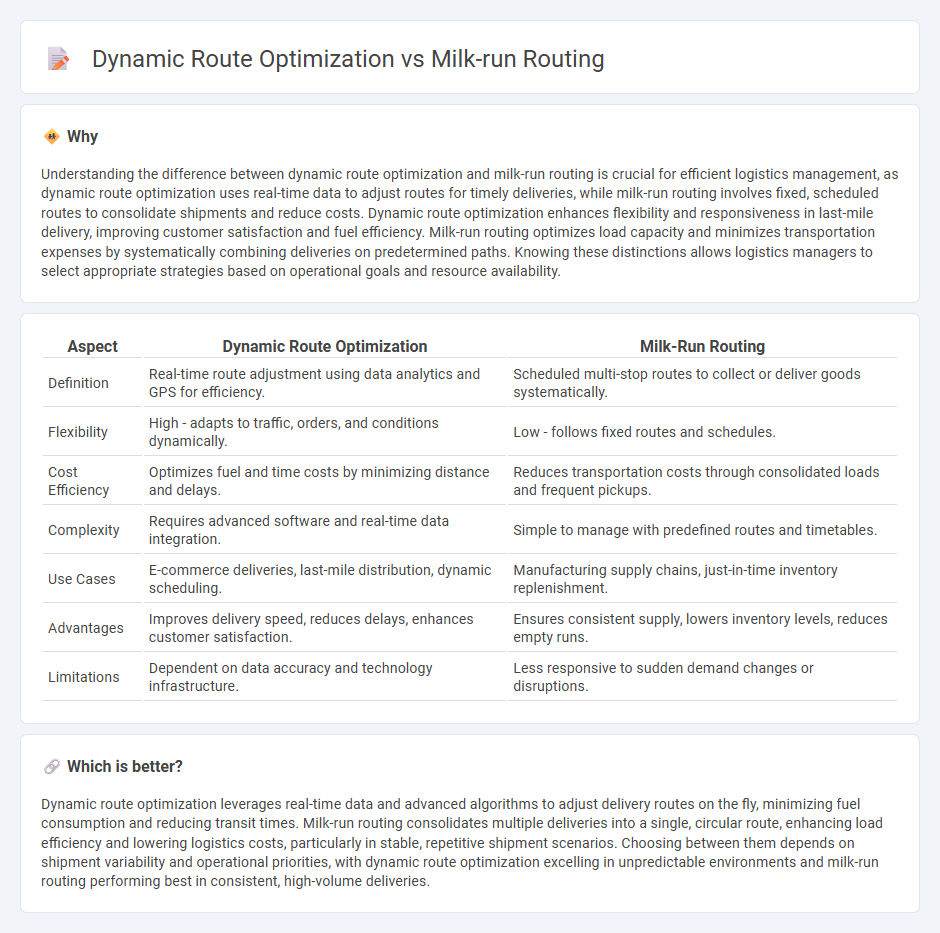

Understanding the difference between dynamic route optimization and milk-run routing is crucial for efficient logistics management, as dynamic route optimization uses real-time data to adjust routes for timely deliveries, while milk-run routing involves fixed, scheduled routes to consolidate shipments and reduce costs. Dynamic route optimization enhances flexibility and responsiveness in last-mile delivery, improving customer satisfaction and fuel efficiency. Milk-run routing optimizes load capacity and minimizes transportation expenses by systematically combining deliveries on predetermined paths. Knowing these distinctions allows logistics managers to select appropriate strategies based on operational goals and resource availability.

Comparison Table

| Aspect | Dynamic Route Optimization | Milk-Run Routing |

|---|---|---|

| Definition | Real-time route adjustment using data analytics and GPS for efficiency. | Scheduled multi-stop routes to collect or deliver goods systematically. |

| Flexibility | High - adapts to traffic, orders, and conditions dynamically. | Low - follows fixed routes and schedules. |

| Cost Efficiency | Optimizes fuel and time costs by minimizing distance and delays. | Reduces transportation costs through consolidated loads and frequent pickups. |

| Complexity | Requires advanced software and real-time data integration. | Simple to manage with predefined routes and timetables. |

| Use Cases | E-commerce deliveries, last-mile distribution, dynamic scheduling. | Manufacturing supply chains, just-in-time inventory replenishment. |

| Advantages | Improves delivery speed, reduces delays, enhances customer satisfaction. | Ensures consistent supply, lowers inventory levels, reduces empty runs. |

| Limitations | Dependent on data accuracy and technology infrastructure. | Less responsive to sudden demand changes or disruptions. |

Which is better?

Dynamic route optimization leverages real-time data and advanced algorithms to adjust delivery routes on the fly, minimizing fuel consumption and reducing transit times. Milk-run routing consolidates multiple deliveries into a single, circular route, enhancing load efficiency and lowering logistics costs, particularly in stable, repetitive shipment scenarios. Choosing between them depends on shipment variability and operational priorities, with dynamic route optimization excelling in unpredictable environments and milk-run routing performing best in consistent, high-volume deliveries.

Connection

Dynamic route optimization enhances milk-run routing by continuously adjusting delivery paths based on real-time data such as traffic conditions, order volumes, and vehicle availability. Milk-run routing benefits from this adaptive approach by minimizing transportation costs and improving load efficiency through consolidated deliveries. Integrating dynamic algorithms ensures timely pickups and drop-offs, driving operational efficiency in supply chain logistics.

Key Terms

**Milk-Run Routing:**

Milk-Run Routing optimizes transportation by consolidating multiple deliveries or pickups along a fixed, repetitive route, reducing transportation costs and improving supply chain efficiency. It lowers fuel consumption and vehicle wear by minimizing empty trips, enhancing sustainability in logistics operations. Explore how Milk-Run Routing transforms supply chain strategies for increased productivity and cost savings.

Fixed Routes

Milk-run routing uses predetermined fixed routes to optimize the collection and delivery of goods, minimizing transportation costs and improving efficiency in supply chain management. Dynamic route optimization adapts routes in real-time based on current conditions like traffic or demand fluctuations, enhancing flexibility but often requiring more complex technology. Explore deeper insights on how fixed routes streamline logistics operations and their impact on cost reduction and service reliability.

Scheduled Pickups

Milk-run routing relies on predetermined schedules and fixed routes to consolidate pickups efficiently, minimizing transportation costs and improving delivery reliability. Dynamic route optimization uses real-time data and algorithms to adjust routes for scheduled pickups based on traffic, demand changes, and other variables, enhancing flexibility and responsiveness. Explore how these strategies impact logistics efficiency and cost savings for businesses with scheduled pickups.

Source and External Links

What Is a Milk Run in Logistics? - A milk run is a delivery route where a single vehicle collects or delivers goods from multiple suppliers or to various customers in one trip to optimize transport efficiency and reduce costs, originally inspired by dairy milk routes.

Milk Run - This method speeds the flow of materials by routing vehicles to make multiple pickups and drop-offs at various facilities, reducing inventory levels and improving response times along the supply chain.

Milk run logistics: what does it consist of? - Milk run logistics consolidates shipments from multiple suppliers on a predetermined route to maximize transport efficiency, minimize costs, and requires precise coordination to avoid shortages and ensure smooth supply chain operations.

dowidth.com

dowidth.com