Pick and pack and kitting are essential logistics processes that streamline order fulfillment and inventory management. Pick and pack involves selecting individual items from inventory and packaging them for shipment, whereas kitting assembles multiple components into a single, ready-to-ship kit or product bundle. Discover how mastering both techniques can optimize your supply chain efficiency and reduce operational costs.

Why it is important

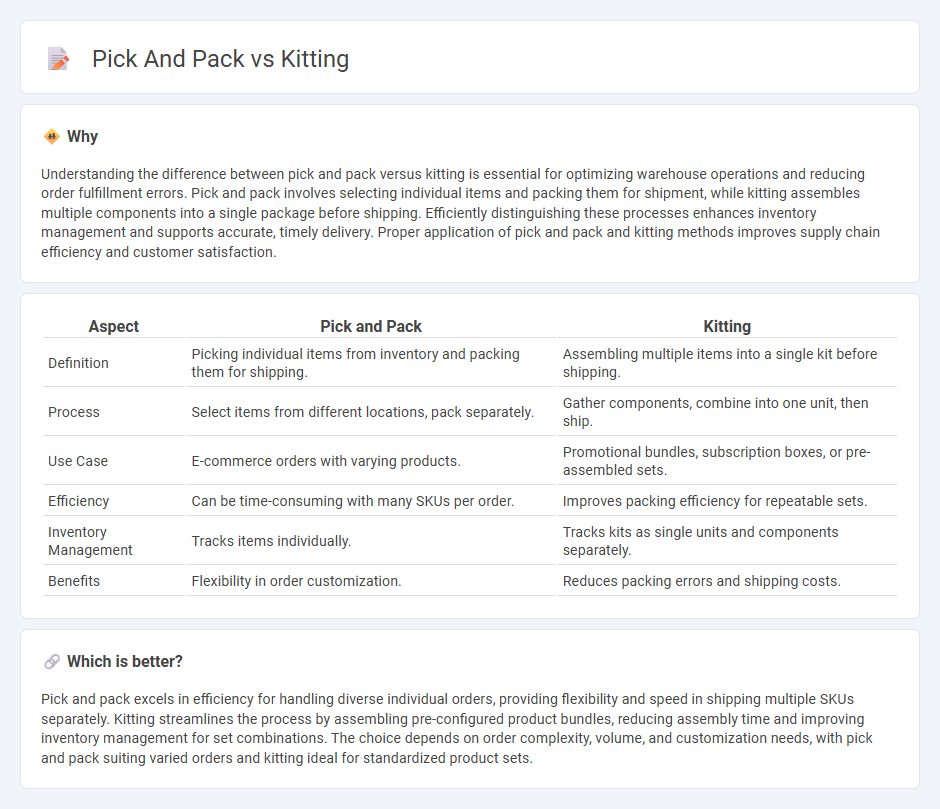

Understanding the difference between pick and pack versus kitting is essential for optimizing warehouse operations and reducing order fulfillment errors. Pick and pack involves selecting individual items and packing them for shipment, while kitting assembles multiple components into a single package before shipping. Efficiently distinguishing these processes enhances inventory management and supports accurate, timely delivery. Proper application of pick and pack and kitting methods improves supply chain efficiency and customer satisfaction.

Comparison Table

| Aspect | Pick and Pack | Kitting |

|---|---|---|

| Definition | Picking individual items from inventory and packing them for shipping. | Assembling multiple items into a single kit before shipping. |

| Process | Select items from different locations, pack separately. | Gather components, combine into one unit, then ship. |

| Use Case | E-commerce orders with varying products. | Promotional bundles, subscription boxes, or pre-assembled sets. |

| Efficiency | Can be time-consuming with many SKUs per order. | Improves packing efficiency for repeatable sets. |

| Inventory Management | Tracks items individually. | Tracks kits as single units and components separately. |

| Benefits | Flexibility in order customization. | Reduces packing errors and shipping costs. |

Which is better?

Pick and pack excels in efficiency for handling diverse individual orders, providing flexibility and speed in shipping multiple SKUs separately. Kitting streamlines the process by assembling pre-configured product bundles, reducing assembly time and improving inventory management for set combinations. The choice depends on order complexity, volume, and customization needs, with pick and pack suiting varied orders and kitting ideal for standardized product sets.

Connection

Pick and pack and kitting processes are interconnected logistics operations that enhance order fulfillment efficiency. Pick and pack involves selecting individual items from inventory and packaging them for shipment, while kitting assembles multiple components into a single ready-to-ship unit. Integrating kitting within pick and pack workflows reduces handling times and streamlines inventory management in supply chain operations.

Key Terms

Assembly

Kitting involves assembling individual components into a ready-to-ship kit, streamlining order fulfillment for complex products. Pick and pack focuses on selecting items from inventory and packaging them for shipment without altering the components. Explore the key differences to optimize your supply chain assembly process efficiently.

Order fulfillment

Kitting consolidates multiple items into a single package before shipping, streamlining bulk order fulfillment and reducing handling errors. Pick and pack involves selecting individual products and packaging them separately, ideal for diverse or small order volumes requiring accuracy. Explore detailed insights into how kitting and pick and pack optimize order fulfillment processes.

Inventory management

Kitting streamlines inventory management by assembling individual components into ready-to-ship kits, reducing storage complexity and improving order accuracy. Pick and pack involves selecting individual items from inventory and packing them separately, which can increase handling time but allows for more customized orders. Explore the benefits and best practices of both methods to optimize your inventory operations.

Source and External Links

Creating and Managing Kits: What is Kitting? - ShipHero - Kitting is the process of packing multiple related products under one SKU into a single package, simplifying customer choices and streamlining fulfillment operations in retail and manufacturing.

Kitting: definitions, processes, and benefits | Red Stag Fulfillment - Kitting involves gathering several products or components into a kit to speed up manufacturing or fulfillment, with uses ranging from assembly tasks to subscription box preparation and promotional packaging.

What is Kitting: Definition, Processes & Benefits - ShipCalm - Kitting includes logistics and warehouse kitting, grouping products either for bulk shipment from manufacturer to retailer or for direct-to-consumer packaging to reduce shipping costs and improve fulfillment efficiency.

dowidth.com

dowidth.com