Green Corridor initiatives prioritize streamlined customs and regulatory processes to accelerate the movement of goods, reducing delays and environmental impact in logistics chains. Just-in-time (JIT) logistics focuses on minimizing inventory levels by synchronizing deliveries precisely with production schedules, enhancing efficiency and reducing storage costs. Explore how these approaches transform supply chain dynamics and improve operational sustainability.

Why it is important

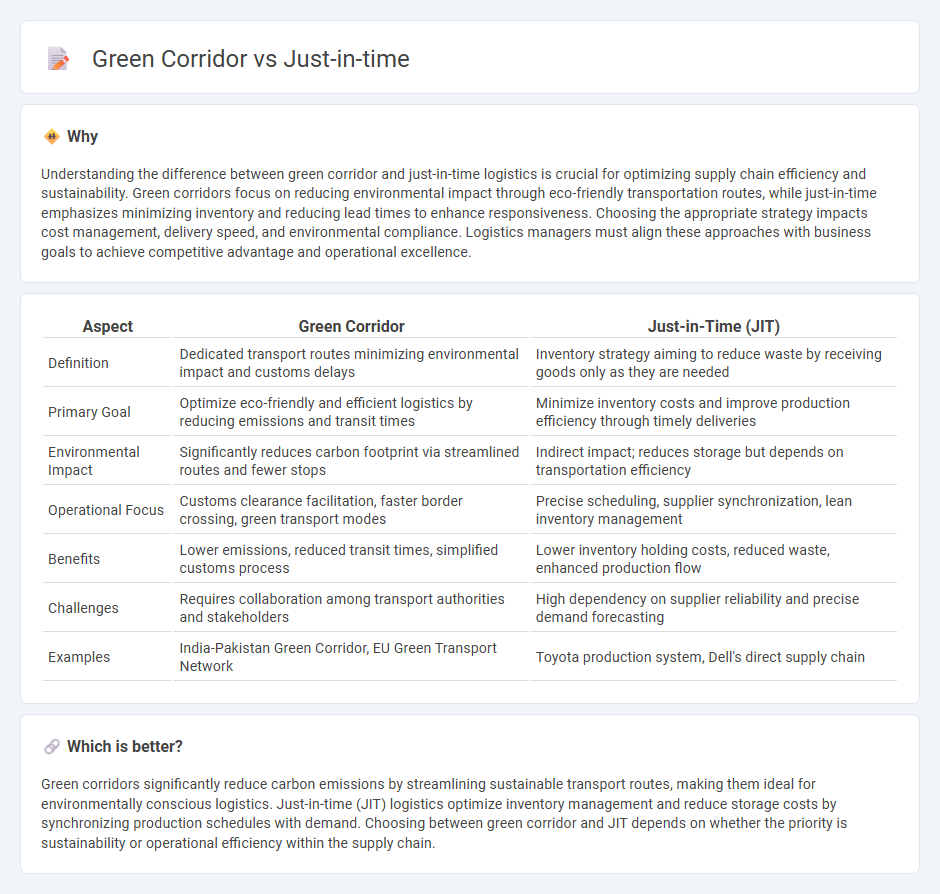

Understanding the difference between green corridor and just-in-time logistics is crucial for optimizing supply chain efficiency and sustainability. Green corridors focus on reducing environmental impact through eco-friendly transportation routes, while just-in-time emphasizes minimizing inventory and reducing lead times to enhance responsiveness. Choosing the appropriate strategy impacts cost management, delivery speed, and environmental compliance. Logistics managers must align these approaches with business goals to achieve competitive advantage and operational excellence.

Comparison Table

| Aspect | Green Corridor | Just-in-Time (JIT) |

|---|---|---|

| Definition | Dedicated transport routes minimizing environmental impact and customs delays | Inventory strategy aiming to reduce waste by receiving goods only as they are needed |

| Primary Goal | Optimize eco-friendly and efficient logistics by reducing emissions and transit times | Minimize inventory costs and improve production efficiency through timely deliveries |

| Environmental Impact | Significantly reduces carbon footprint via streamlined routes and fewer stops | Indirect impact; reduces storage but depends on transportation efficiency |

| Operational Focus | Customs clearance facilitation, faster border crossing, green transport modes | Precise scheduling, supplier synchronization, lean inventory management |

| Benefits | Lower emissions, reduced transit times, simplified customs process | Lower inventory holding costs, reduced waste, enhanced production flow |

| Challenges | Requires collaboration among transport authorities and stakeholders | High dependency on supplier reliability and precise demand forecasting |

| Examples | India-Pakistan Green Corridor, EU Green Transport Network | Toyota production system, Dell's direct supply chain |

Which is better?

Green corridors significantly reduce carbon emissions by streamlining sustainable transport routes, making them ideal for environmentally conscious logistics. Just-in-time (JIT) logistics optimize inventory management and reduce storage costs by synchronizing production schedules with demand. Choosing between green corridor and JIT depends on whether the priority is sustainability or operational efficiency within the supply chain.

Connection

Green corridor initiatives optimize supply chain routes to reduce carbon emissions, aligning perfectly with just-in-time (JIT) logistics that emphasize precise delivery timing and minimal inventory. By ensuring efficient, timely transport, green corridors enable JIT systems to minimize waste and lower the environmental footprint of inventory management. This synergy enhances sustainability and operational efficiency in logistics networks.

Key Terms

Inventory Management

Just-in-time (JIT) inventory management aims to minimize stock levels by synchronizing production schedules with demand, reducing holding costs and waste. Green corridors enhance supply chain efficiency by creating dedicated, sustainable routes that promote faster transit and lower environmental impact, supporting timely material availability. Explore the strategic benefits of integrating JIT with green corridor logistics for optimal inventory control and sustainability.

Emissions Reduction

Just-in-time (JIT) logistics minimizes inventory storage and reduces waste by synchronizing supply chain activities, leading to lower carbon emissions due to decreased warehousing and transportation inefficiencies. Green corridors prioritize sustainable transport routes by integrating low-emission vehicles, renewable energy sources, and eco-friendly infrastructure to significantly cut down on greenhouse gas emissions. Explore how these innovative strategies contribute to emissions reduction and drive sustainability in modern supply chains.

Real-time Tracking

Real-time tracking plays a crucial role in both just-in-time (JIT) and green corridor logistics by enhancing supply chain visibility and reducing transit delays. JIT relies on precise delivery timing supported by continuous shipment monitoring, while green corridors utilize real-time data to expedite customs clearance and ensure smooth, uninterrupted flow of goods. Explore how real-time tracking technologies transform efficiency across these innovative logistics strategies.

Source and External Links

Just-in-Time (JIT) Inventory: A Definition and Comprehensive Guide - Just-in-Time (JIT) is an inventory management strategy where materials arrive exactly as needed for production, minimizing inventory levels and waste while requiring close supplier collaboration to meet demand precisely.

JIT Just-in-Time manufacturing - JIT is a management philosophy focused on producing only what is needed, when needed, eliminating waste through continuous improvement, quality control, simplicity, and techniques like Kanban and autonomous machines.

What is Just-In-Time Manufacturing (JIT)? - Planview - JIT manufacturing is a workflow methodology developed post-WWII in Japan to reduce production times, inventory, and costs by producing small batches to respond quickly to demand, famously used in the Toyota Production System.

dowidth.com

dowidth.com