Cold chain visibility involves real-time monitoring of temperature, humidity, and location data to ensure product quality throughout transportation and storage in the logistics sector. Cold chain management encompasses the strategic planning, execution, and control of these processes to prevent spoilage and comply with industry standards such as ISO 22000 and GDP guidelines. Discover how advanced technologies enhance both visibility and management to optimize cold chain logistics.

Why it is important

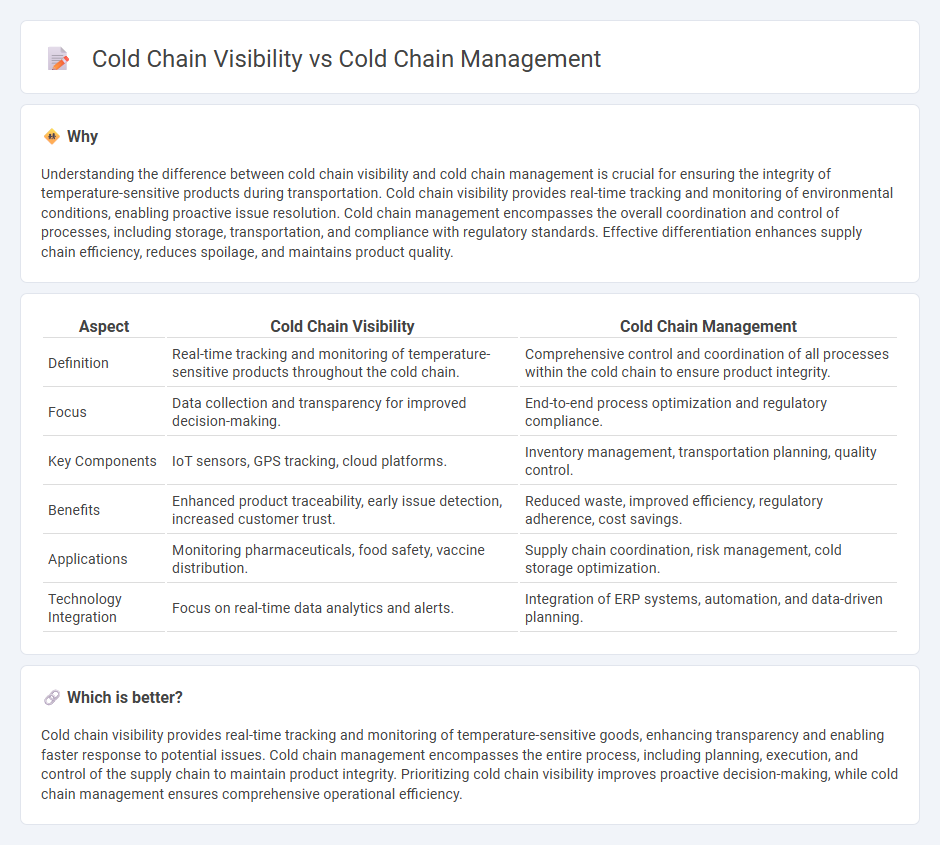

Understanding the difference between cold chain visibility and cold chain management is crucial for ensuring the integrity of temperature-sensitive products during transportation. Cold chain visibility provides real-time tracking and monitoring of environmental conditions, enabling proactive issue resolution. Cold chain management encompasses the overall coordination and control of processes, including storage, transportation, and compliance with regulatory standards. Effective differentiation enhances supply chain efficiency, reduces spoilage, and maintains product quality.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Management |

|---|---|---|

| Definition | Real-time tracking and monitoring of temperature-sensitive products throughout the cold chain. | Comprehensive control and coordination of all processes within the cold chain to ensure product integrity. |

| Focus | Data collection and transparency for improved decision-making. | End-to-end process optimization and regulatory compliance. |

| Key Components | IoT sensors, GPS tracking, cloud platforms. | Inventory management, transportation planning, quality control. |

| Benefits | Enhanced product traceability, early issue detection, increased customer trust. | Reduced waste, improved efficiency, regulatory adherence, cost savings. |

| Applications | Monitoring pharmaceuticals, food safety, vaccine distribution. | Supply chain coordination, risk management, cold storage optimization. |

| Technology Integration | Focus on real-time data analytics and alerts. | Integration of ERP systems, automation, and data-driven planning. |

Which is better?

Cold chain visibility provides real-time tracking and monitoring of temperature-sensitive goods, enhancing transparency and enabling faster response to potential issues. Cold chain management encompasses the entire process, including planning, execution, and control of the supply chain to maintain product integrity. Prioritizing cold chain visibility improves proactive decision-making, while cold chain management ensures comprehensive operational efficiency.

Connection

Cold chain visibility enhances cold chain management by providing real-time tracking and monitoring of temperature-sensitive products throughout the supply chain, ensuring compliance with safety standards. Advanced IoT sensors and data analytics enable proactive identification of potential disruptions, minimizing spoilage and maintaining product integrity. Efficient cold chain management relies on this visibility to optimize route planning, inventory control, and regulatory adherence, ultimately improving overall logistics performance.

Key Terms

**Cold Chain Management:**

Cold Chain Management involves the systematic control of temperature-sensitive products throughout the entire supply chain to preserve quality and safety, ensuring compliance with regulatory standards and reducing spoilage. It includes the integration of specialized storage equipment, transportation methods, and monitoring technologies to maintain the required temperature range from production to delivery. Discover more about how advanced cold chain management solutions enhance product integrity and operational efficiency.

Temperature Control

Cold chain management encompasses the entire process of maintaining optimal temperature conditions from production to delivery, ensuring product integrity. Cold chain visibility specifically refers to the real-time monitoring and tracking of temperature data throughout the supply chain to prevent temperature deviations. Explore how leveraging advanced sensors and IoT technologies can enhance temperature control in your cold chain operations.

Refrigerated Transportation

Cold chain management in refrigerated transportation ensures temperature-controlled environments, maintaining product quality from origin to destination. Cold chain visibility enhances this process by providing real-time tracking and monitoring of temperature, humidity, and location data to prevent spoilage or delays. Discover how integrating advanced cold chain visibility solutions optimizes refrigerated transportation for maximum efficiency and safety.

Source and External Links

What is Cold Chain Management? - Cold chain management involves controlling all phases of temperature-sensitive products' journey, including storage, packaging, tracking, transportation, customs clearance, product handling, and delivery to maintain product quality and safety.

What is Cold Chain Management & Logistics? - Cold chain management ensures the precise temperature control of perishable goods across the supply chain, relying on regulated compliance, specialized packaging, and advanced real-time temperature monitoring technologies to maintain product integrity.

Pharmaceutical Cold Chain Management in Health Systems (ASHP) - Effective cold chain management in healthcare requires preparedness for disruptions, system designs to reduce losses, redundancy plans, and holistic coordination to ensure continuous access to temperature-sensitive pharmaceuticals.

dowidth.com

dowidth.com