Cold chain management ensures the integrity of temperature-sensitive products by maintaining precise environmental conditions throughout the supply chain, reducing spoilage and preserving quality. Demand forecasting leverages data analytics and market insights to predict customer demand, optimizing inventory levels and minimizing stockouts or overstock situations. Explore how integrating cold chain management with demand forecasting can enhance efficiency and reliability in logistics.

Why it is important

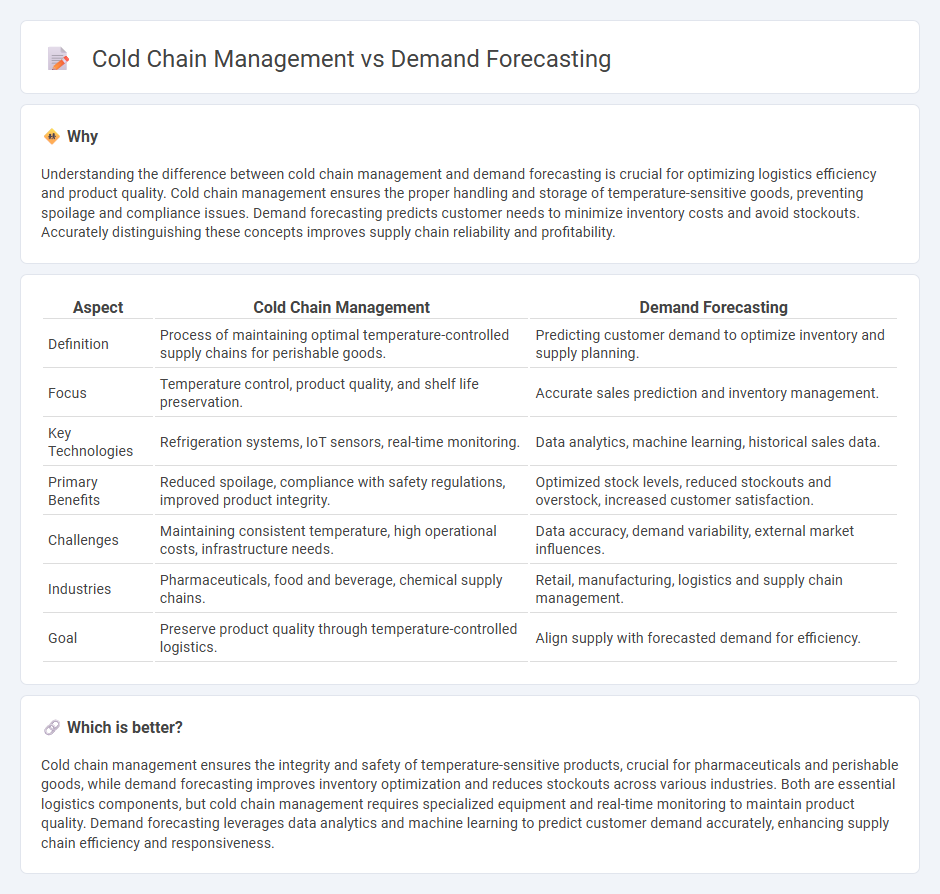

Understanding the difference between cold chain management and demand forecasting is crucial for optimizing logistics efficiency and product quality. Cold chain management ensures the proper handling and storage of temperature-sensitive goods, preventing spoilage and compliance issues. Demand forecasting predicts customer needs to minimize inventory costs and avoid stockouts. Accurately distinguishing these concepts improves supply chain reliability and profitability.

Comparison Table

| Aspect | Cold Chain Management | Demand Forecasting |

|---|---|---|

| Definition | Process of maintaining optimal temperature-controlled supply chains for perishable goods. | Predicting customer demand to optimize inventory and supply planning. |

| Focus | Temperature control, product quality, and shelf life preservation. | Accurate sales prediction and inventory management. |

| Key Technologies | Refrigeration systems, IoT sensors, real-time monitoring. | Data analytics, machine learning, historical sales data. |

| Primary Benefits | Reduced spoilage, compliance with safety regulations, improved product integrity. | Optimized stock levels, reduced stockouts and overstock, increased customer satisfaction. |

| Challenges | Maintaining consistent temperature, high operational costs, infrastructure needs. | Data accuracy, demand variability, external market influences. |

| Industries | Pharmaceuticals, food and beverage, chemical supply chains. | Retail, manufacturing, logistics and supply chain management. |

| Goal | Preserve product quality through temperature-controlled logistics. | Align supply with forecasted demand for efficiency. |

Which is better?

Cold chain management ensures the integrity and safety of temperature-sensitive products, crucial for pharmaceuticals and perishable goods, while demand forecasting improves inventory optimization and reduces stockouts across various industries. Both are essential logistics components, but cold chain management requires specialized equipment and real-time monitoring to maintain product quality. Demand forecasting leverages data analytics and machine learning to predict customer demand accurately, enhancing supply chain efficiency and responsiveness.

Connection

Cold chain management relies heavily on accurate demand forecasting to ensure perishable goods are stored and transported at optimal temperatures without overstocking or understocking. Precise demand forecasts enable logistics providers to plan cold storage capacity and transportation routes, minimizing spoilage and reducing operational costs. Integrating real-time demand data with cold chain systems enhances inventory management and improves overall supply chain efficiency.

Key Terms

**Demand forecasting:**

Demand forecasting leverages historical sales data, market trends, and consumer behavior to predict future product demand with high accuracy, optimizing inventory levels and reducing stockouts. Accurate demand forecasting is crucial for industries like retail and logistics, where aligning supply with anticipated demand minimizes costs and enhances customer satisfaction. Explore more insights into how demand forecasting drives efficient supply chain operations.

Historical data analysis

Historical data analysis in demand forecasting involves examining past sales patterns, seasonality, and market trends to predict future product demand accurately, ensuring inventory aligns with customer needs. In cold chain management, analyzing historical temperature records and handling conditions helps identify vulnerabilities and optimize storage and transportation processes to maintain product quality. Explore more to understand how leveraging historical data can enhance efficiency in both demand forecasting and cold chain management.

Predictive analytics

Demand forecasting leverages predictive analytics to anticipate consumer purchasing patterns by analyzing historical sales data, seasonal trends, and market conditions, enabling businesses to optimize inventory levels and reduce stockouts. Cold chain management utilizes predictive analytics to monitor and control temperature-sensitive products, ensuring quality and safety through real-time data from IoT sensors and environmental factors. Explore how integrating predictive analytics enhances both demand forecasting and cold chain management for operational excellence.

Source and External Links

Types of Demand Forecast - Demand forecasting uses predictive analysis of past data to anticipate future customer demand, aiding businesses in inventory planning, production, pricing, and other supply-related decisions by examining historical data and various forecasting methods.

Demand Forecasting: A Complete Guide - Demand forecasting enables companies to predict future market demands, optimize supply chains, reduce costs, and respond quickly to market changes by using techniques like trend analysis, market research, and advanced analytics for improved business performance.

Demand forecasting: types, methods, and examples - Demand forecasting estimates future product demand through methods such as trend projection, market research, and salesperson input to guide production and inventory to meet consumer needs efficiently.

dowidth.com

dowidth.com