Silent delivery streamlines supply chain operations by minimizing handling and storage time, ensuring products move directly from supplier to customer without unnecessary delays. Cross-docking optimizes warehouse efficiency by rapidly transferring goods from inbound to outbound transportation, reducing inventory holding costs and enhancing order fulfillment speed. Explore the advantages and applications of silent delivery and cross-docking to improve your logistics strategy.

Why it is important

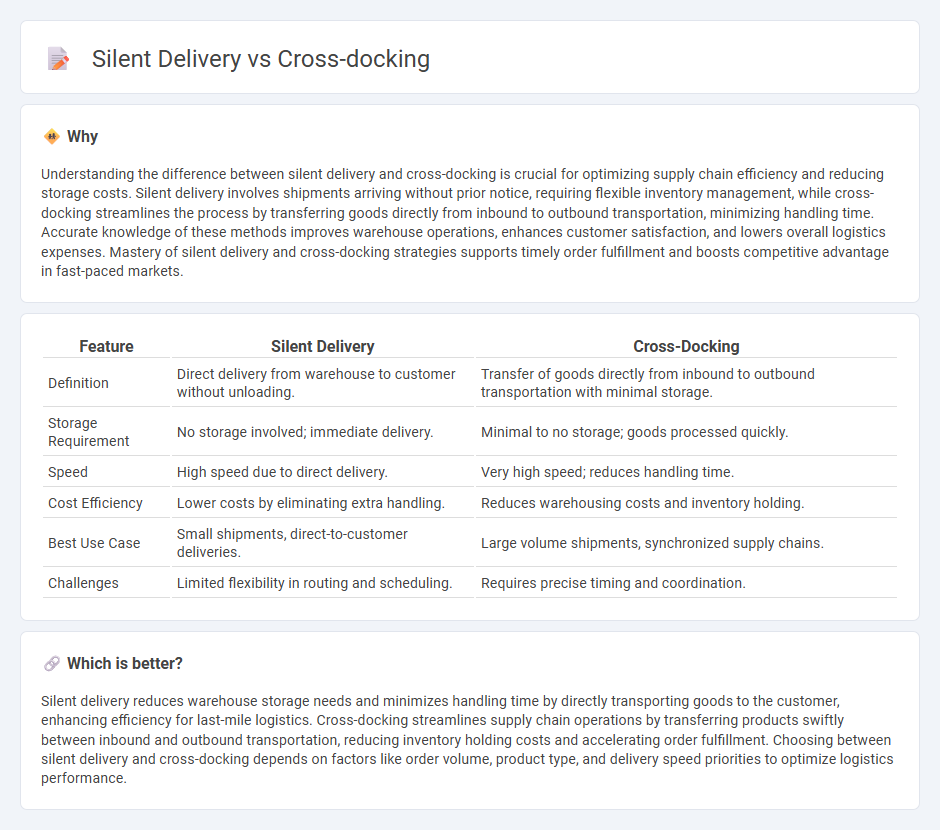

Understanding the difference between silent delivery and cross-docking is crucial for optimizing supply chain efficiency and reducing storage costs. Silent delivery involves shipments arriving without prior notice, requiring flexible inventory management, while cross-docking streamlines the process by transferring goods directly from inbound to outbound transportation, minimizing handling time. Accurate knowledge of these methods improves warehouse operations, enhances customer satisfaction, and lowers overall logistics expenses. Mastery of silent delivery and cross-docking strategies supports timely order fulfillment and boosts competitive advantage in fast-paced markets.

Comparison Table

| Feature | Silent Delivery | Cross-Docking |

|---|---|---|

| Definition | Direct delivery from warehouse to customer without unloading. | Transfer of goods directly from inbound to outbound transportation with minimal storage. |

| Storage Requirement | No storage involved; immediate delivery. | Minimal to no storage; goods processed quickly. |

| Speed | High speed due to direct delivery. | Very high speed; reduces handling time. |

| Cost Efficiency | Lower costs by eliminating extra handling. | Reduces warehousing costs and inventory holding. |

| Best Use Case | Small shipments, direct-to-customer deliveries. | Large volume shipments, synchronized supply chains. |

| Challenges | Limited flexibility in routing and scheduling. | Requires precise timing and coordination. |

Which is better?

Silent delivery reduces warehouse storage needs and minimizes handling time by directly transporting goods to the customer, enhancing efficiency for last-mile logistics. Cross-docking streamlines supply chain operations by transferring products swiftly between inbound and outbound transportation, reducing inventory holding costs and accelerating order fulfillment. Choosing between silent delivery and cross-docking depends on factors like order volume, product type, and delivery speed priorities to optimize logistics performance.

Connection

Silent delivery minimizes noise pollution during nighttime or urban logistics operations, enabling efficient off-peak transportation. Cross-docking streamlines the supply chain by rapidly transferring goods from inbound to outbound vehicles without storage, enhancing delivery speed and reducing handling costs. Integrating silent delivery with cross-docking optimizes last-mile logistics in densely populated areas, improving efficiency and minimizing disturbances.

Key Terms

Transshipment

Cross-docking streamlines inventory flow by directly transferring goods from inbound to outbound transport, minimizing storage time within the warehouse. Silent delivery emphasizes discreet, efficient transshipment processes to reduce disruptions and maintain supply chain secrecy. Discover key strategies to optimize transshipment efficiency through targeted logistics methods.

Noise Regulation

Cross-docking streamlines logistics by transferring incoming goods directly to outbound transport, minimizing storage time and operational noise. Silent delivery methods emphasize reducing noise pollution through electric vehicles and quiet handling equipment, aligning closely with stringent urban noise regulations. Explore the impact of noise regulation on modern delivery techniques to optimize efficiency and environmental compliance.

Real-time Tracking

Cross-docking streamlines logistics by transferring shipments directly from inbound to outbound transportation with minimal storage, enhancing real-time tracking accuracy through immediate data updates. Silent delivery emphasizes discretion and minimal notification, often limiting the availability of real-time tracking information to maintain privacy and security. Explore the benefits and challenges of both methods to optimize your supply chain visibility and efficiency.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method that transfers goods directly from receiving to shipping areas with minimal storage, using methods like continuous flow, consolidation of shipments, and de-consolidation into smaller batches to improve efficiency and reduce costs.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain strategy that moves products directly from inbound to outbound transportation with little to no storage time, speeding up deliveries, minimizing warehouse space needs, and cutting costs.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking involves direct transfer of goods with minimal storage, categorized by pre-distribution or post-distribution sorting, and processes like continuous, consolidation, and deconsolidation to meet different industry needs such as retail, manufacturing, and e-commerce.

dowidth.com

dowidth.com