Dynamic rerouting enhances supply chain efficiency by adjusting delivery paths in real-time based on traffic, weather, and demand fluctuations, reducing delays and transportation costs. Inventory allocation strategically distributes products across multiple warehouses to meet regional demand accurately and minimize stockouts. Discover how integrating dynamic rerouting with inventory allocation optimizes logistics performance and customer satisfaction.

Why it is important

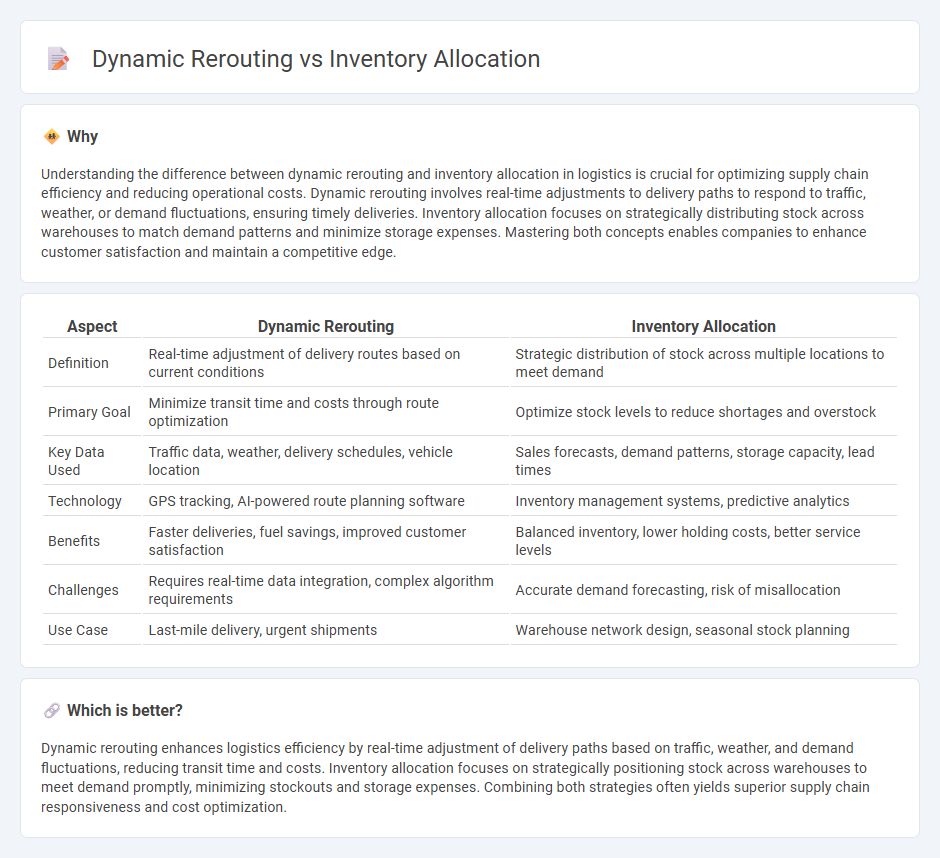

Understanding the difference between dynamic rerouting and inventory allocation in logistics is crucial for optimizing supply chain efficiency and reducing operational costs. Dynamic rerouting involves real-time adjustments to delivery paths to respond to traffic, weather, or demand fluctuations, ensuring timely deliveries. Inventory allocation focuses on strategically distributing stock across warehouses to match demand patterns and minimize storage expenses. Mastering both concepts enables companies to enhance customer satisfaction and maintain a competitive edge.

Comparison Table

| Aspect | Dynamic Rerouting | Inventory Allocation |

|---|---|---|

| Definition | Real-time adjustment of delivery routes based on current conditions | Strategic distribution of stock across multiple locations to meet demand |

| Primary Goal | Minimize transit time and costs through route optimization | Optimize stock levels to reduce shortages and overstock |

| Key Data Used | Traffic data, weather, delivery schedules, vehicle location | Sales forecasts, demand patterns, storage capacity, lead times |

| Technology | GPS tracking, AI-powered route planning software | Inventory management systems, predictive analytics |

| Benefits | Faster deliveries, fuel savings, improved customer satisfaction | Balanced inventory, lower holding costs, better service levels |

| Challenges | Requires real-time data integration, complex algorithm requirements | Accurate demand forecasting, risk of misallocation |

| Use Case | Last-mile delivery, urgent shipments | Warehouse network design, seasonal stock planning |

Which is better?

Dynamic rerouting enhances logistics efficiency by real-time adjustment of delivery paths based on traffic, weather, and demand fluctuations, reducing transit time and costs. Inventory allocation focuses on strategically positioning stock across warehouses to meet demand promptly, minimizing stockouts and storage expenses. Combining both strategies often yields superior supply chain responsiveness and cost optimization.

Connection

Dynamic rerouting in logistics optimizes transportation routes in real time based on current traffic, weather, and demand conditions, directly influencing inventory allocation by ensuring timely delivery and stock distribution. Efficient inventory allocation relies on accurate, adaptive routing data to balance supply across multiple warehouses and reduce holding costs. Integrating these processes enhances supply chain responsiveness, minimizes delays, and improves overall operational efficiency.

Key Terms

**Inventory Allocation:**

Inventory allocation optimizes stock distribution across multiple locations to meet demand efficiently and reduce costs associated with overstock or stockouts. Dynamic rerouting adapts the delivery path in real-time, responding to changing conditions such as traffic or customer availability. Explore how strategic inventory allocation can enhance supply chain efficiency and responsiveness.

Stock Levels

Inventory allocation prioritizes distributing stock based on current stock levels across warehouses to meet demand efficiently, reducing overstock and stockouts. Dynamic rerouting adjusts shipments in real-time to redirect inventory flows where stock depletion or surges occur, ensuring optimal stock availability. Explore these strategies further to enhance your supply chain efficiency and responsiveness.

Demand Forecasting

Inventory allocation leverages demand forecasting to strategically distribute stock across multiple locations, ensuring optimal availability and minimizing stockouts. Dynamic rerouting adjusts shipments en route based on real-time demand fluctuations and updated forecasts, enhancing delivery responsiveness and reducing transportation costs. Explore how integrating advanced demand forecasting in these strategies can improve supply chain efficiency and customer satisfaction.

Source and External Links

Inventory Allocation: Best Practices and Considerations (2024) - Inventory allocation is the distribution of products across storage locations and sales channels using methods such as pull, push, just-in-time (JIT), and first-in, first-out (FIFO) to manage stock based on demand, forecast, timing, and product type.

Inventory Allocation - Salsify - Inventory allocation is the process of assigning specific amounts of inventory to various locations in a distribution network, enhancing visibility, optimizing stock levels, and enabling better response to market changes and consumer demand.

Inventory Allocation Defined: Methods & Best Practices - NetSuite - Inventory allocation strategically distributes inventory aligned with customer demand across locations to keep shelves stocked, enable fast order fulfillment, optimize warehouse space, and facilitate manufacturing with adequate materials available.

dowidth.com

dowidth.com