Entrepreneurship in the alt protein sector is rapidly advancing with innovations that address sustainability, scalability, and consumer demand for ethical food sources. Scalable meat processing technologies focus on increasing production efficiency while reducing environmental impact, presenting significant opportunities for startups to disrupt traditional meat industries. Explore how these emerging ventures are reshaping the future of food sustainability and market growth.

Why it is important

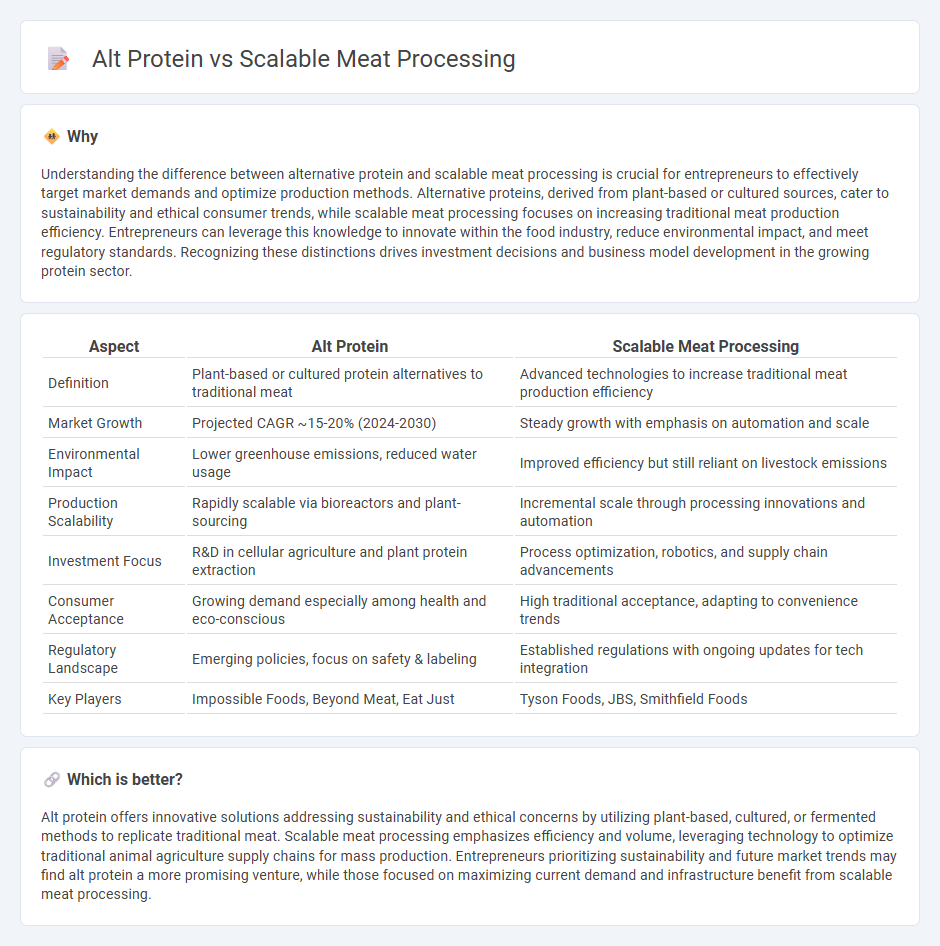

Understanding the difference between alternative protein and scalable meat processing is crucial for entrepreneurs to effectively target market demands and optimize production methods. Alternative proteins, derived from plant-based or cultured sources, cater to sustainability and ethical consumer trends, while scalable meat processing focuses on increasing traditional meat production efficiency. Entrepreneurs can leverage this knowledge to innovate within the food industry, reduce environmental impact, and meet regulatory standards. Recognizing these distinctions drives investment decisions and business model development in the growing protein sector.

Comparison Table

| Aspect | Alt Protein | Scalable Meat Processing |

|---|---|---|

| Definition | Plant-based or cultured protein alternatives to traditional meat | Advanced technologies to increase traditional meat production efficiency |

| Market Growth | Projected CAGR ~15-20% (2024-2030) | Steady growth with emphasis on automation and scale |

| Environmental Impact | Lower greenhouse emissions, reduced water usage | Improved efficiency but still reliant on livestock emissions |

| Production Scalability | Rapidly scalable via bioreactors and plant-sourcing | Incremental scale through processing innovations and automation |

| Investment Focus | R&D in cellular agriculture and plant protein extraction | Process optimization, robotics, and supply chain advancements |

| Consumer Acceptance | Growing demand especially among health and eco-conscious | High traditional acceptance, adapting to convenience trends |

| Regulatory Landscape | Emerging policies, focus on safety & labeling | Established regulations with ongoing updates for tech integration |

| Key Players | Impossible Foods, Beyond Meat, Eat Just | Tyson Foods, JBS, Smithfield Foods |

Which is better?

Alt protein offers innovative solutions addressing sustainability and ethical concerns by utilizing plant-based, cultured, or fermented methods to replicate traditional meat. Scalable meat processing emphasizes efficiency and volume, leveraging technology to optimize traditional animal agriculture supply chains for mass production. Entrepreneurs prioritizing sustainability and future market trends may find alt protein a more promising venture, while those focused on maximizing current demand and infrastructure benefit from scalable meat processing.

Connection

Alt protein innovation drives entrepreneurship by creating scalable meat processing technologies that meet growing consumer demand for sustainable, ethical alternatives to traditional meat. Startups invest in bioprocessing techniques such as cell culture and fermentation to develop efficient, cost-effective production lines that can operate at industrial scale. This integration accelerates market entry and attracts investment, fueling the growth of the alternative protein industry.

Key Terms

Production Efficiency

Meat processing scalability emphasizes high-throughput systems, automated slaughtering, and optimized supply chains to maximize production efficiency while minimizing resource use and waste. Alternative protein production prioritizes bioreactor optimization, cell culture growth rate improvements, and precision fermentation to reduce cost per unit and energy consumption at scale. Explore detailed comparisons on how each approach advances manufacturing efficiency in the evolving protein industry.

Supply Chain Integration

Scalable meat processing leverages established supply chain networks for efficient sourcing, production, and distribution of animal proteins, ensuring consistent product availability and cost-effectiveness. Alternative protein supply chains require strategic integration of novel raw materials, specialized processing technologies, and emerging distribution channels to meet growing consumer demand. Explore further to understand how supply chain integration drives innovation and sustainability in protein production.

Technological Differentiation

Scalable meat processing leverages advanced automation, robotics, and AI-driven quality control systems to enhance efficiency and reduce production costs at industrial volumes. Alternative protein technologies emphasize cellular agriculture, fermentation, and plant-based innovations to replicate traditional meat textures and flavors while minimizing environmental impact. Explore the latest breakthroughs in technological differentiation shaping the future of protein production.

Source and External Links

Scalable manufacturing process for cultivated meat - Food Processing - A new continuous manufacturing process using tangential flow filtration enables high cell density growth and daily biomass harvests, potentially making cultivated meat production economically scalable without genetic modification or mega-factories.

Trends in cultivated meat scale-up and bioprocessing - The cultivated meat industry is transitioning from kilogram-scale production to using large bioreactors for ton-scale outputs, employing various bioprocessing strategies tailored to different cell types with ongoing challenges in regulatory and techno-economic optimization.

Meat Processing Systems | Built For Local Meat Processing - Friesla - Friesla offers scalable, modular USDA-compliant meat processing plants designed for onsite, small- to mid-scale processing, allowing local producers complete control over slaughter, processing, and packaging in a compact, integrated system.

dowidth.com

dowidth.com