Print on demand offers entrepreneurs low upfront costs and minimal inventory risks by producing items only when orders are placed, making it ideal for testing new product ideas. Custom manufacturing involves higher investment and longer lead times but allows for greater control over product quality and branding, suitable for scaling established businesses. Explore the advantages and challenges of each model to determine which aligns best with your entrepreneurial goals.

Why it is important

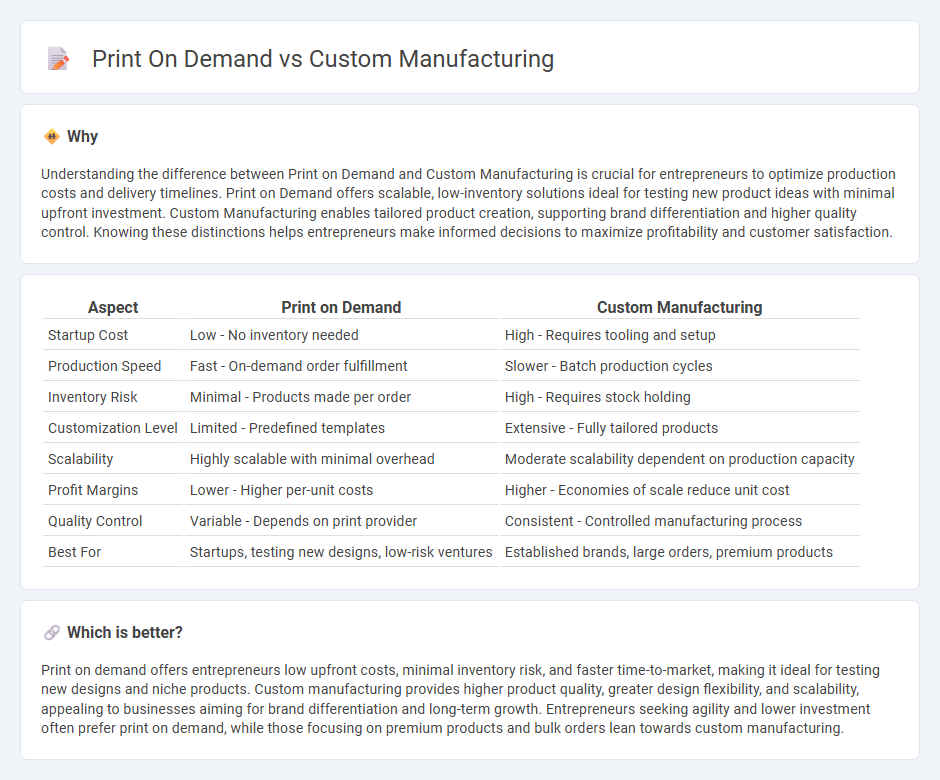

Understanding the difference between Print on Demand and Custom Manufacturing is crucial for entrepreneurs to optimize production costs and delivery timelines. Print on Demand offers scalable, low-inventory solutions ideal for testing new product ideas with minimal upfront investment. Custom Manufacturing enables tailored product creation, supporting brand differentiation and higher quality control. Knowing these distinctions helps entrepreneurs make informed decisions to maximize profitability and customer satisfaction.

Comparison Table

| Aspect | Print on Demand | Custom Manufacturing |

|---|---|---|

| Startup Cost | Low - No inventory needed | High - Requires tooling and setup |

| Production Speed | Fast - On-demand order fulfillment | Slower - Batch production cycles |

| Inventory Risk | Minimal - Products made per order | High - Requires stock holding |

| Customization Level | Limited - Predefined templates | Extensive - Fully tailored products |

| Scalability | Highly scalable with minimal overhead | Moderate scalability dependent on production capacity |

| Profit Margins | Lower - Higher per-unit costs | Higher - Economies of scale reduce unit cost |

| Quality Control | Variable - Depends on print provider | Consistent - Controlled manufacturing process |

| Best For | Startups, testing new designs, low-risk ventures | Established brands, large orders, premium products |

Which is better?

Print on demand offers entrepreneurs low upfront costs, minimal inventory risk, and faster time-to-market, making it ideal for testing new designs and niche products. Custom manufacturing provides higher product quality, greater design flexibility, and scalability, appealing to businesses aiming for brand differentiation and long-term growth. Entrepreneurs seeking agility and lower investment often prefer print on demand, while those focusing on premium products and bulk orders lean towards custom manufacturing.

Connection

Print on demand and custom manufacturing both enable entrepreneurs to create personalized products without maintaining inventory, reducing upfront costs and minimizing financial risks. These models leverage digital platforms and on-demand production technologies to quickly fulfill unique customer orders, enhancing scalability and market responsiveness. By integrating print on demand with custom manufacturing, businesses can offer highly tailored merchandise with efficient supply chain management, driving innovation and competitive advantage.

Key Terms

Inventory Management

Custom manufacturing requires precise inventory management to handle raw materials and finished goods, reducing waste and storage costs. Print on demand eliminates inventory buildup by producing items only after an order is placed, streamlining supply chains and minimizing capital tied up in stock. Explore how each method impacts operational efficiency and financial outcomes to make an informed decision.

Production Flexibility

Custom manufacturing offers high production flexibility with tailored batch sizes and material choices, allowing precise adaptation to specific design requirements or market changes. Print on demand excels in on-demand, small-scale production with minimal setup time, ideal for testing product variations and reducing inventory risks. Explore detailed comparisons to determine which production flexibility best suits your business model.

Order Fulfillment

Custom manufacturing offers precise control over order fulfillment timelines and product quality by producing items in batches tailored to specific client requirements. Print on demand excels in quick turnaround and minimal inventory risk, producing single items per order but may face delays due to reliance on third-party printers. Explore detailed comparisons to determine the best order fulfillment method for your business needs.

Source and External Links

Custom Manufacturing: Processes, Benefits, and Applications - Custom manufacturing involves creating unique parts in smaller quantities to meet exact specifications, utilizing processes like additive manufacturing (3D printing methods) and subtractive manufacturing (CNC machining, EDM, etc.) for efficient, customizable production.

Custom Manufacturing | OneMonroe - OneMonroe specializes in custom manufacturing solutions with the ability to produce built-to-order parts, short-run components, and large fabrication programs, emphasizing engineering reviews to optimize cost and quality.

Custom Manufacturing Corp. - Bensalem - Custom Manufacturing Corp. offers comprehensive metal forming services including stretch bending, compression bending, draw bending, roll bending, and CNC machining, all provided under one roof with decades of experience since 1957.

dowidth.com

dowidth.com