Fragmented supply chains consist of multiple independent entities working in isolation, leading to inefficiencies and increased risks, while linear supply chains follow a sequential, streamlined process with clear, end-to-end control that enhances predictability and coordination. Global disruptions like the COVID-19 pandemic exposed vulnerabilities in fragmented supply chains, prompting businesses to reevaluate the resilience of their logistics models. Explore how evolving supply chain strategies impact economic stability and growth opportunities.

Why it is important

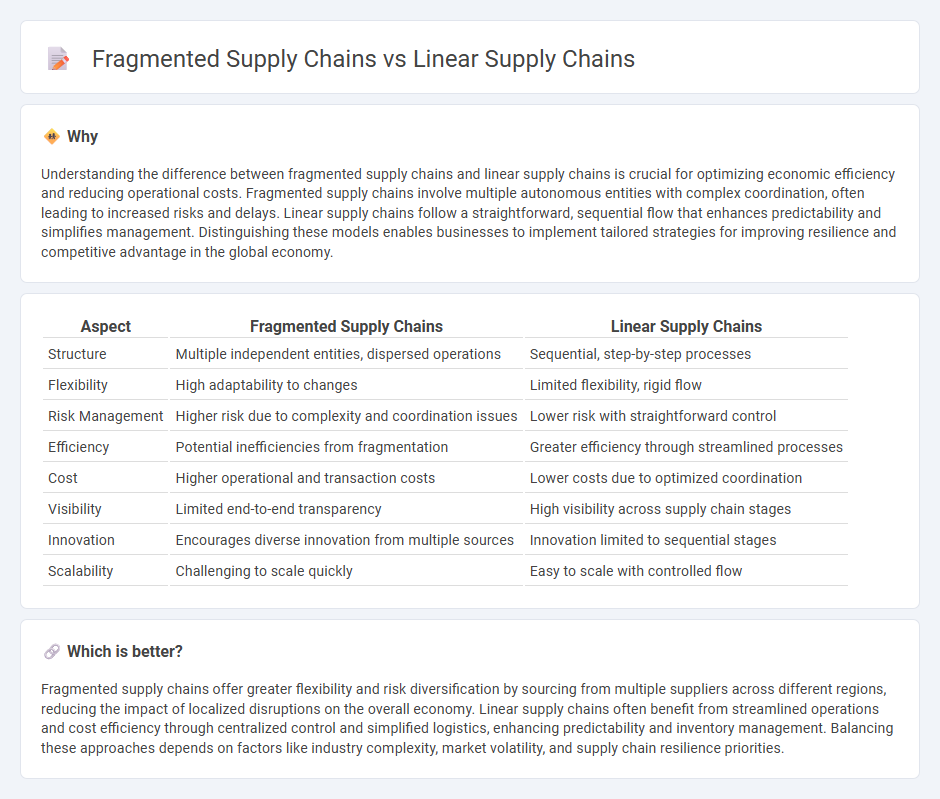

Understanding the difference between fragmented supply chains and linear supply chains is crucial for optimizing economic efficiency and reducing operational costs. Fragmented supply chains involve multiple autonomous entities with complex coordination, often leading to increased risks and delays. Linear supply chains follow a straightforward, sequential flow that enhances predictability and simplifies management. Distinguishing these models enables businesses to implement tailored strategies for improving resilience and competitive advantage in the global economy.

Comparison Table

| Aspect | Fragmented Supply Chains | Linear Supply Chains |

|---|---|---|

| Structure | Multiple independent entities, dispersed operations | Sequential, step-by-step processes |

| Flexibility | High adaptability to changes | Limited flexibility, rigid flow |

| Risk Management | Higher risk due to complexity and coordination issues | Lower risk with straightforward control |

| Efficiency | Potential inefficiencies from fragmentation | Greater efficiency through streamlined processes |

| Cost | Higher operational and transaction costs | Lower costs due to optimized coordination |

| Visibility | Limited end-to-end transparency | High visibility across supply chain stages |

| Innovation | Encourages diverse innovation from multiple sources | Innovation limited to sequential stages |

| Scalability | Challenging to scale quickly | Easy to scale with controlled flow |

Which is better?

Fragmented supply chains offer greater flexibility and risk diversification by sourcing from multiple suppliers across different regions, reducing the impact of localized disruptions on the overall economy. Linear supply chains often benefit from streamlined operations and cost efficiency through centralized control and simplified logistics, enhancing predictability and inventory management. Balancing these approaches depends on factors like industry complexity, market volatility, and supply chain resilience priorities.

Connection

Fragmented supply chains consist of isolated, uncoordinated segments that hinder seamless material flow, while linear supply chains follow a straightforward, sequential process from raw materials to end consumers. The connection lies in how fragmentation disrupts the efficiency of linear supply chains by creating delays, increasing costs, and reducing responsiveness. Improving integration and communication across fragmented segments enhances the overall resilience and performance of linear supply chains in a dynamic economy.

Key Terms

Vertical Integration

Vertical integration enhances linear supply chains by consolidating production stages under single ownership, improving coordination and reducing costs, leading to streamlined operations and increased efficiency. In contrast, fragmented supply chains often lack cohesive control, resulting in complexities, higher transaction costs, and reduced responsiveness to market changes. Explore the benefits and challenges of vertical integration to optimize supply chain performance.

Decentralization

Decentralized supply chains distribute decision-making and operations across multiple independent nodes, enhancing flexibility and responsiveness compared to the centralized control in linear supply chains. Fragmented supply chains, often decentralized, face challenges in coordination but benefit from increased resilience and local adaptability. Explore further to understand how decentralization impacts efficiency, risk management, and scalability in different supply chain models.

Intermediaries

Linear supply chains rely on a sequential flow where intermediaries such as wholesalers and distributors play a crucial role in moving products from manufacturers to retailers, ensuring smooth transitions and inventory management. Fragmented supply chains involve multiple autonomous entities, creating complexity for intermediaries who must coordinate various suppliers and buyers across decentralized networks, often requiring advanced communication and logistics solutions. Explore deeper insights on how intermediaries impact efficiency and risk management in these contrasting supply chain structures.

Source and External Links

Linear vs. Circular Supply Chains - UNEX Blog - A linear supply chain is a traditional business model characterized by the sequence "Take Make Dispose," relying on cheap raw materials and focusing on minimizing costs, but it is increasingly seen as unsustainable due to environmental impacts and waste accumulation.

The Anatomy of a Circular Supply Chain | Flat World Global Solutions - A linear supply chain moves goods in one direction from raw material to end user, ending with disposal, unlike circular supply chains which recover and reuse products via reverse logistics.

Example of Supply Chain Transition | Circular Economy - UNL CMS - Linear supply chains consist of producers, processors, retailers, and consumers, with material flow strictly from start to finish, generating waste and byproducts that are usually discarded rather than reused or recycled.

dowidth.com

dowidth.com