Onshoring involves relocating business processes or manufacturing back to the company's home country to reduce costs and improve supply chain reliability. Insourcing refers to the practice of using internal resources and employees to perform tasks previously outsourced, enhancing control and quality. Explore the nuances between onshoring and insourcing to understand their impact on economic growth and operational efficiency.

Why it is important

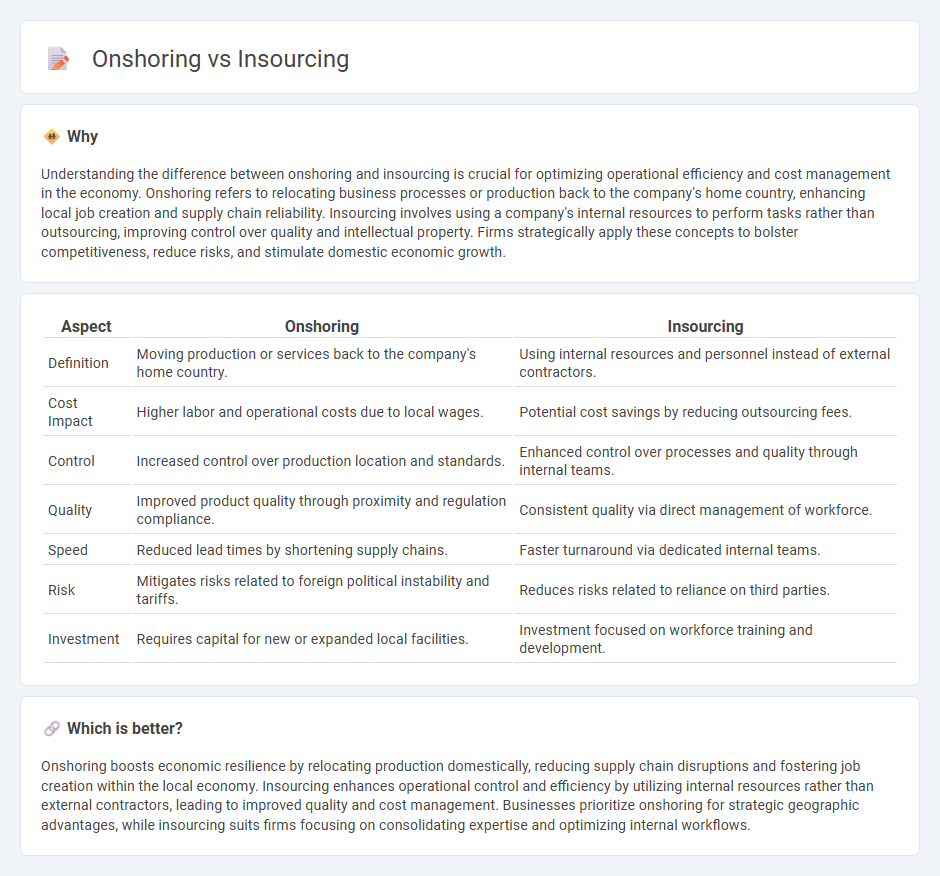

Understanding the difference between onshoring and insourcing is crucial for optimizing operational efficiency and cost management in the economy. Onshoring refers to relocating business processes or production back to the company's home country, enhancing local job creation and supply chain reliability. Insourcing involves using a company's internal resources to perform tasks rather than outsourcing, improving control over quality and intellectual property. Firms strategically apply these concepts to bolster competitiveness, reduce risks, and stimulate domestic economic growth.

Comparison Table

| Aspect | Onshoring | Insourcing |

|---|---|---|

| Definition | Moving production or services back to the company's home country. | Using internal resources and personnel instead of external contractors. |

| Cost Impact | Higher labor and operational costs due to local wages. | Potential cost savings by reducing outsourcing fees. |

| Control | Increased control over production location and standards. | Enhanced control over processes and quality through internal teams. |

| Quality | Improved product quality through proximity and regulation compliance. | Consistent quality via direct management of workforce. |

| Speed | Reduced lead times by shortening supply chains. | Faster turnaround via dedicated internal teams. |

| Risk | Mitigates risks related to foreign political instability and tariffs. | Reduces risks related to reliance on third parties. |

| Investment | Requires capital for new or expanded local facilities. | Investment focused on workforce training and development. |

Which is better?

Onshoring boosts economic resilience by relocating production domestically, reducing supply chain disruptions and fostering job creation within the local economy. Insourcing enhances operational control and efficiency by utilizing internal resources rather than external contractors, leading to improved quality and cost management. Businesses prioritize onshoring for strategic geographic advantages, while insourcing suits firms focusing on consolidating expertise and optimizing internal workflows.

Connection

Onshoring and insourcing both contribute to strengthening domestic economic growth by relocating production and business processes back to the home country. Onshoring specifically involves moving manufacturing or services from foreign locations to local facilities, while insourcing focuses on utilizing internal resources and labor instead of outsourcing tasks. Together, these strategies reduce dependency on international supply chains, increase job creation, and enhance control over quality and operational efficiency.

Key Terms

Labor Costs

Insourcing involves using a company's internal workforce to perform tasks, which can lead to higher control but potentially increased labor costs due to local wage standards. Onshoring shifts operations to domestic locations, often reducing labor costs compared to offshore alternatives while benefiting from proximity and regulatory alignment. Explore detailed comparisons of labor cost impacts between insourcing and onshoring strategies to make informed decisions.

Supply Chain

Insourcing involves managing and performing supply chain functions internally within a company, enhancing control over production quality and timelines. Onshoring shifts supply chain operations closer to the domestic market, reducing logistics costs, lead times, and risks associated with overseas disruptions. Explore detailed insights to optimize your supply chain strategy effectively.

Domestic Production

Insourcing domestic production reduces reliance on external suppliers by utilizing in-house resources and expertise, enhancing quality control, and streamlining operations. Onshoring shifts production back to the home country, promoting local job creation, reducing transportation costs, and minimizing supply chain disruptions. Explore the benefits and challenges of insourcing versus onshoring in optimizing domestic manufacturing strategies.

Source and External Links

What Is Insourcing and How It Works (With Examples) - Insourcing is bringing staff into a company from other sources to build internal capacity, creating work within the company under direct control rather than outsourcing it outside.

What Is Insourcing? Definition, Benefits, And Examples - Insourcing assigns tasks to internal employees or departments instead of external vendors, improving quality control, cost management, and operational flexibility through use of existing organizational resources.

Insourcing - Definition, Examples & FAQ - Insourcing means performing work internally by utilizing company talent rather than delegating externally, involving identification of tasks, evaluation of internal capabilities, and monitoring for efficiency and quality.

dowidth.com

dowidth.com