Digital twin simulation creates a dynamic virtual model of physical processes, enabling real-time monitoring and predictive analysis, while Value Stream Mapping visually identifies waste and inefficiencies within workflows to enhance process optimization. Consulting services leverage these tools to improve operational performance, reduce costs, and accelerate decision-making through data-driven insights. Discover how integrating digital twin simulation and Value Stream Mapping can revolutionize your business strategies.

Why it is important

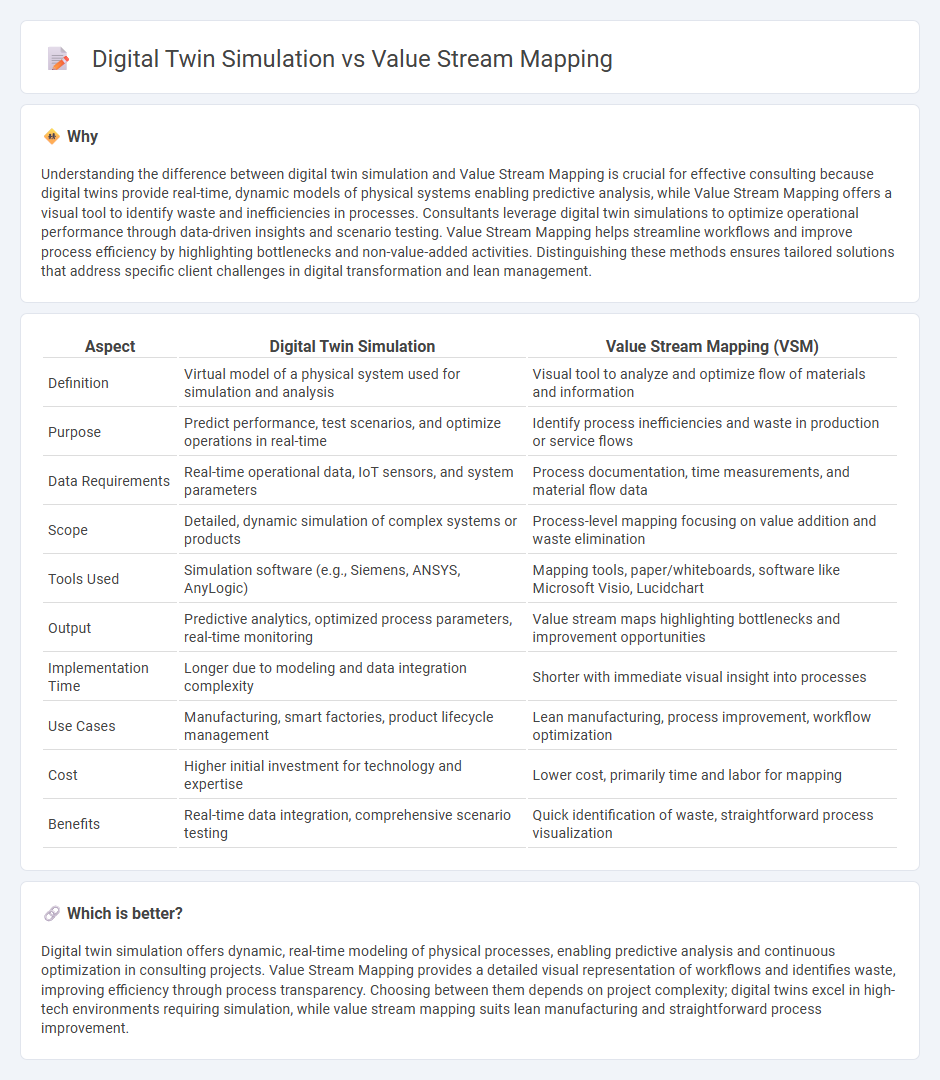

Understanding the difference between digital twin simulation and Value Stream Mapping is crucial for effective consulting because digital twins provide real-time, dynamic models of physical systems enabling predictive analysis, while Value Stream Mapping offers a visual tool to identify waste and inefficiencies in processes. Consultants leverage digital twin simulations to optimize operational performance through data-driven insights and scenario testing. Value Stream Mapping helps streamline workflows and improve process efficiency by highlighting bottlenecks and non-value-added activities. Distinguishing these methods ensures tailored solutions that address specific client challenges in digital transformation and lean management.

Comparison Table

| Aspect | Digital Twin Simulation | Value Stream Mapping (VSM) |

|---|---|---|

| Definition | Virtual model of a physical system used for simulation and analysis | Visual tool to analyze and optimize flow of materials and information |

| Purpose | Predict performance, test scenarios, and optimize operations in real-time | Identify process inefficiencies and waste in production or service flows |

| Data Requirements | Real-time operational data, IoT sensors, and system parameters | Process documentation, time measurements, and material flow data |

| Scope | Detailed, dynamic simulation of complex systems or products | Process-level mapping focusing on value addition and waste elimination |

| Tools Used | Simulation software (e.g., Siemens, ANSYS, AnyLogic) | Mapping tools, paper/whiteboards, software like Microsoft Visio, Lucidchart |

| Output | Predictive analytics, optimized process parameters, real-time monitoring | Value stream maps highlighting bottlenecks and improvement opportunities |

| Implementation Time | Longer due to modeling and data integration complexity | Shorter with immediate visual insight into processes |

| Use Cases | Manufacturing, smart factories, product lifecycle management | Lean manufacturing, process improvement, workflow optimization |

| Cost | Higher initial investment for technology and expertise | Lower cost, primarily time and labor for mapping |

| Benefits | Real-time data integration, comprehensive scenario testing | Quick identification of waste, straightforward process visualization |

Which is better?

Digital twin simulation offers dynamic, real-time modeling of physical processes, enabling predictive analysis and continuous optimization in consulting projects. Value Stream Mapping provides a detailed visual representation of workflows and identifies waste, improving efficiency through process transparency. Choosing between them depends on project complexity; digital twins excel in high-tech environments requiring simulation, while value stream mapping suits lean manufacturing and straightforward process improvement.

Connection

Digital twin simulation enhances Value Stream Mapping by providing real-time, virtual replicas of production processes that enable precise identification of bottlenecks and inefficiencies. Integrating these technologies allows consultants to visualize process flows dynamically, improving accuracy in value stream analyses and facilitating data-driven decision-making. This connection accelerates continuous improvement initiatives by simulating potential changes before implementation, reducing operational risks and optimizing resource allocation.

Key Terms

Process Visualization

Value Stream Mapping (VSM) provides a static, high-level visualization of manufacturing processes by mapping material and information flows, identifying waste and bottlenecks for lean improvement. Digital twin simulation offers a dynamic, real-time virtual model of processes, enabling detailed analysis, scenario testing, and optimization through continuous data integration and predictive analytics. Explore how combining VSM with digital twin simulation enhances process visualization and drives operational excellence.

Real-time Data Modeling

Value Stream Mapping (VSM) provides a visual representation of workflow to identify waste and optimize processes, relying primarily on static data collected from observations and time studies. Digital twin simulation leverages real-time data modeling by creating dynamic, virtual replicas of physical systems, enabling continuous monitoring and predictive analysis for enhanced decision-making. Explore how integrating these methodologies can revolutionize operational efficiency in your industry.

Continuous Improvement

Value Stream Mapping (VSM) visually identifies inefficiencies in production by mapping material and information flows, while digital twin simulation creates dynamic virtual models for real-time process optimization and scenario testing. Both tools enhance continuous improvement by enabling precise data-driven decisions; VSM targets workflow transparency, whereas digital twins offer predictive insights and performance forecasting. Explore how combining VSM with digital twin simulation can revolutionize your continuous improvement strategies.

Source and External Links

Value stream mapping for software delivery - Dora.dev - Value Stream Mapping (VSM) is a lean management practice that visualizes the entire flow of work, from idea to production, identifying bottlenecks and quantifying wait times to improve software delivery processes.

Value-stream mapping - Wikipedia - Value stream mapping is a lean-management method used to analyze and design the flow of materials and information through a process, aiming to identify and eliminate waste to increase efficiency across manufacturing, logistics, software development, and other industries.

Value Stream Mapping Overview - Lean Enterprise Institute - VSM diagrams every step of the material and information flows needed to bring a product from order to delivery, focusing on creating current and future state maps to continuously improve and eliminate waste in the value stream.

dowidth.com

dowidth.com