Cost-to-serve analysis focuses on calculating the precise expenses associated with delivering products or services to customers, revealing profitability at granular levels. Supply chain optimization enhances overall efficiency by streamlining processes, improving inventory management, and reducing lead times across the entire supply network. Discover how integrating cost-to-serve analysis with supply chain optimization drives strategic decision-making and maximizes operational performance.

Why it is important

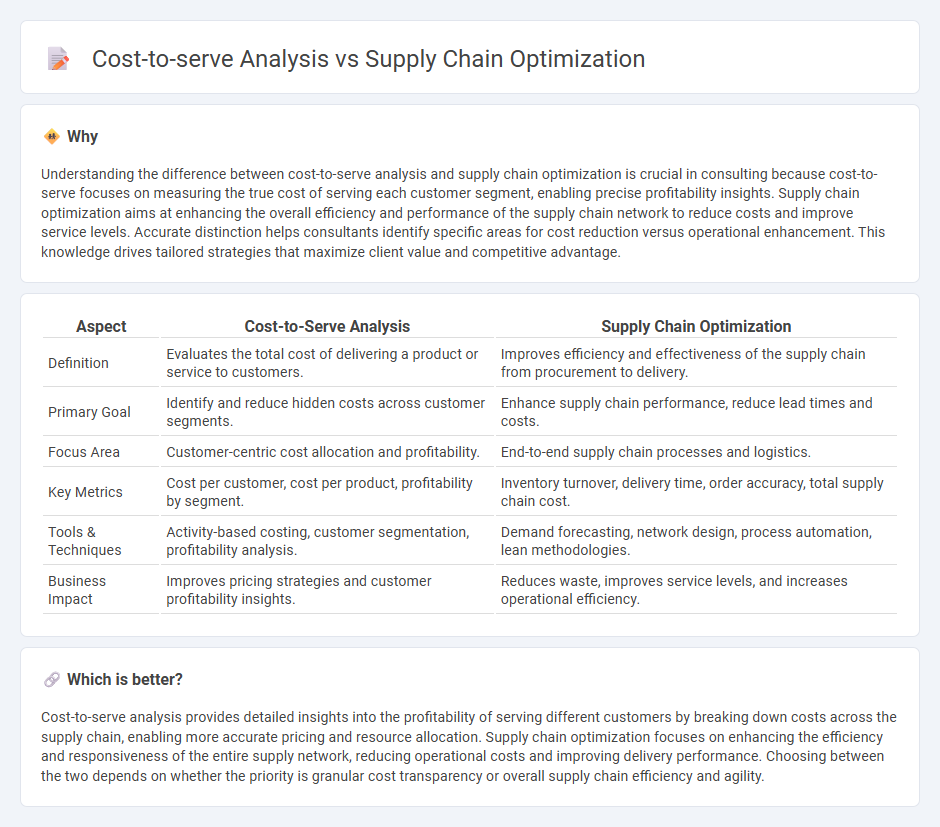

Understanding the difference between cost-to-serve analysis and supply chain optimization is crucial in consulting because cost-to-serve focuses on measuring the true cost of serving each customer segment, enabling precise profitability insights. Supply chain optimization aims at enhancing the overall efficiency and performance of the supply chain network to reduce costs and improve service levels. Accurate distinction helps consultants identify specific areas for cost reduction versus operational enhancement. This knowledge drives tailored strategies that maximize client value and competitive advantage.

Comparison Table

| Aspect | Cost-to-Serve Analysis | Supply Chain Optimization |

|---|---|---|

| Definition | Evaluates the total cost of delivering a product or service to customers. | Improves efficiency and effectiveness of the supply chain from procurement to delivery. |

| Primary Goal | Identify and reduce hidden costs across customer segments. | Enhance supply chain performance, reduce lead times and costs. |

| Focus Area | Customer-centric cost allocation and profitability. | End-to-end supply chain processes and logistics. |

| Key Metrics | Cost per customer, cost per product, profitability by segment. | Inventory turnover, delivery time, order accuracy, total supply chain cost. |

| Tools & Techniques | Activity-based costing, customer segmentation, profitability analysis. | Demand forecasting, network design, process automation, lean methodologies. |

| Business Impact | Improves pricing strategies and customer profitability insights. | Reduces waste, improves service levels, and increases operational efficiency. |

Which is better?

Cost-to-serve analysis provides detailed insights into the profitability of serving different customers by breaking down costs across the supply chain, enabling more accurate pricing and resource allocation. Supply chain optimization focuses on enhancing the efficiency and responsiveness of the entire supply network, reducing operational costs and improving delivery performance. Choosing between the two depends on whether the priority is granular cost transparency or overall supply chain efficiency and agility.

Connection

Cost-to-serve analysis identifies the true expenses associated with serving each customer segment, enabling targeted improvements in supply chain processes. Supply chain optimization uses these insights to streamline inventory management, reduce transportation costs, and enhance service levels. This connection drives more efficient resource allocation and boosts overall profitability.

Key Terms

Demand Forecasting

Supply chain optimization integrates demand forecasting to enhance inventory management, reduce lead times, and improve service levels by predicting customer demand accurately. Cost-to-serve analysis leverages demand forecasting to allocate costs based on customer orders and delivery requirements, identifying areas for cost reduction and resource allocation. Explore how advanced demand forecasting techniques can transform both supply chain optimization and cost-to-serve strategies for your business.

Network Design

Supply chain optimization leverages advanced network design to enhance efficiency by strategically positioning warehouses, distribution centers, and transportation routes, reducing lead times and overall operational costs. Cost-to-serve analysis breaks down expenses linked to serving individual customers or channels, highlighting profitability variations and enabling more informed decisions within the network architecture. Explore how integrating network design with cost-to-serve insights can revolutionize your supply chain strategy and drive sustainable growth.

Customer Profitability

Supply chain optimization enhances customer profitability by streamlining processes, reducing lead times, and minimizing inventory costs, resulting in improved service levels and increased margins. Cost-to-serve analysis provides a detailed breakdown of the expenses associated with serving each customer segment, enabling businesses to identify unprofitable customers and tailor strategies accordingly. Discover how integrating these approaches can maximize customer profitability and drive better decision-making.

Source and External Links

The Ultimate Guide to Supply Chain Optimization - Order.co - Supply chain optimization improves production and distribution efficiency and quality, using tactics like assessing current practices, improving planning, continual negotiation, expanding analytics, and automating processes to reduce costs and enhance performance.

What is Supply Chain Optimization? - Tibco - Supply chain optimization adjusts operations to peak efficiency by managing quality, cost, inventory, and network optimization, enabling companies to reduce costs, improve service levels, and strategically adapt their supply networks.

What Is Supply Chain Optimization? - Oracle - This ongoing process involves improving efficiency and cost-effectiveness across sourcing, production, and delivery through detailed analysis, demand-aligned planning, and execution supported by technologies for inventory and transportation management, with continuous reassessment to adopt new innovations.

dowidth.com

dowidth.com