Cost-to-serve analysis identifies precise expenses linked to delivering products or services by tracing costs across the supply chain, enabling targeted improvements in profitability and resource allocation. Lean assessment focuses on eliminating waste and enhancing process efficiency through value stream mapping and continuous improvement principles, driving operational excellence. Explore how combining cost-to-serve analysis with Lean assessment can unlock deeper insights and optimize your business performance.

Why it is important

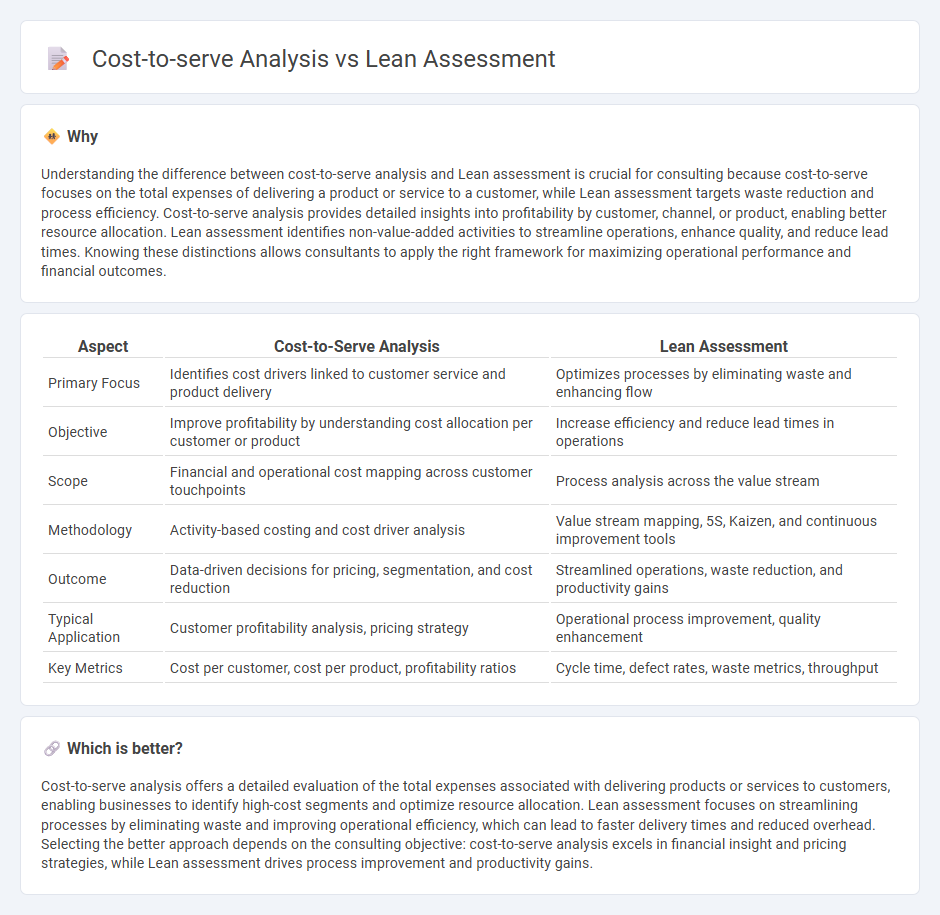

Understanding the difference between cost-to-serve analysis and Lean assessment is crucial for consulting because cost-to-serve focuses on the total expenses of delivering a product or service to a customer, while Lean assessment targets waste reduction and process efficiency. Cost-to-serve analysis provides detailed insights into profitability by customer, channel, or product, enabling better resource allocation. Lean assessment identifies non-value-added activities to streamline operations, enhance quality, and reduce lead times. Knowing these distinctions allows consultants to apply the right framework for maximizing operational performance and financial outcomes.

Comparison Table

| Aspect | Cost-to-Serve Analysis | Lean Assessment |

|---|---|---|

| Primary Focus | Identifies cost drivers linked to customer service and product delivery | Optimizes processes by eliminating waste and enhancing flow |

| Objective | Improve profitability by understanding cost allocation per customer or product | Increase efficiency and reduce lead times in operations |

| Scope | Financial and operational cost mapping across customer touchpoints | Process analysis across the value stream |

| Methodology | Activity-based costing and cost driver analysis | Value stream mapping, 5S, Kaizen, and continuous improvement tools |

| Outcome | Data-driven decisions for pricing, segmentation, and cost reduction | Streamlined operations, waste reduction, and productivity gains |

| Typical Application | Customer profitability analysis, pricing strategy | Operational process improvement, quality enhancement |

| Key Metrics | Cost per customer, cost per product, profitability ratios | Cycle time, defect rates, waste metrics, throughput |

Which is better?

Cost-to-serve analysis offers a detailed evaluation of the total expenses associated with delivering products or services to customers, enabling businesses to identify high-cost segments and optimize resource allocation. Lean assessment focuses on streamlining processes by eliminating waste and improving operational efficiency, which can lead to faster delivery times and reduced overhead. Selecting the better approach depends on the consulting objective: cost-to-serve analysis excels in financial insight and pricing strategies, while Lean assessment drives process improvement and productivity gains.

Connection

Cost-to-serve analysis identifies the total expenses involved in delivering a product or service to customers, while Lean assessment focuses on eliminating waste and improving process efficiency. Together, these methodologies enable organizations to pinpoint cost drivers and optimize operational workflows, enhancing profitability and customer value. Integrating cost-to-serve insights with Lean tools streamlines resource allocation and sharpens strategic decision-making in consulting projects.

Key Terms

Value Stream Mapping

Lean assessment and cost-to-serve analysis both leverage Value Stream Mapping (VSM) to identify inefficiencies and optimize processes within supply chains. Lean assessment emphasizes waste reduction and process flow improvement, while cost-to-serve analysis focuses on quantifying the total cost associated with delivering products to customers. Explore more about how Value Stream Mapping enhances strategic decision-making for operational efficiency.

Activity-Based Costing

Lean assessment identifies process inefficiencies and waste within operations to enhance productivity and reduce cycle times. Cost-to-serve analysis leverages Activity-Based Costing (ABC) to allocate indirect and direct costs accurately to specific customer segments or products, revealing profitability drivers. Explore how integrating Lean principles with Activity-Based Costing can optimize operational costs and value delivery.

Process Efficiency

Lean assessment targets the elimination of waste and streamlining workflows to enhance process efficiency through continuous improvement methodologies like value stream mapping and Kaizen. Cost-to-serve analysis evaluates the total cost associated with delivering a product or service, identifying inefficiencies across the supply chain that impact profitability and operational performance. Explore how integrating Lean assessment with cost-to-serve analysis can drive comprehensive process optimization and cost reduction.

Source and External Links

Seizing Success: The Power of Lean Assessments - A Lean Assessment is a diagnostic tool that evaluates manufacturing operations to identify inefficiencies and set a baseline for continuous improvement, serving as a critical first step in a Lean Transformation journey.

LEAN ENTERPRISE SELF ASSESSMENT TOOL - The LESAT tool assesses Lean maturity across organizational practices, helping determine current status and set improvement goals, with documentation facilitating corrective actions and continuous improvement.

Assessment for Lean Manufacturing - This Lean Manufacturing assessment evaluates nine key areas through questionnaires and scoring, producing a Lean Index and radar chart to benchmark and prioritize improvement based on strategic relevance.

dowidth.com

dowidth.com