Organizational Network Analysis (ONA) maps and measures relationships and information flow within a company, revealing informal networks that drive collaboration and innovation. Lean Management focuses on minimizing waste and optimizing processes to enhance operational efficiency and value delivery. Explore how combining these approaches can transform organizational performance and agility.

Why it is important

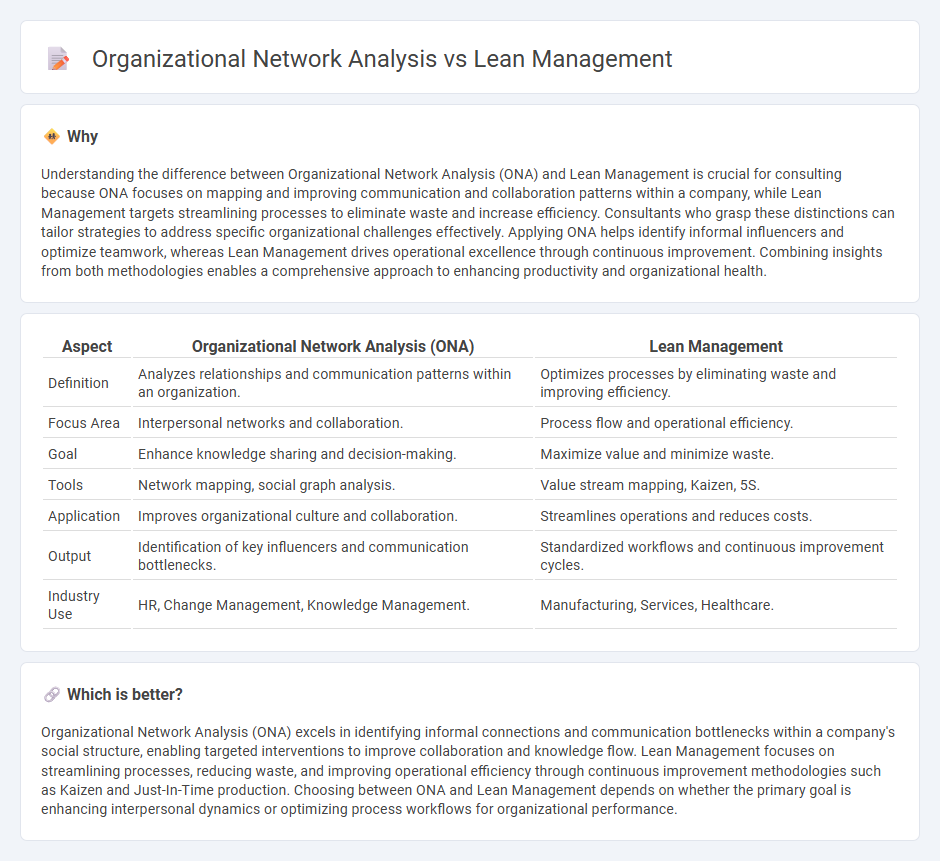

Understanding the difference between Organizational Network Analysis (ONA) and Lean Management is crucial for consulting because ONA focuses on mapping and improving communication and collaboration patterns within a company, while Lean Management targets streamlining processes to eliminate waste and increase efficiency. Consultants who grasp these distinctions can tailor strategies to address specific organizational challenges effectively. Applying ONA helps identify informal influencers and optimize teamwork, whereas Lean Management drives operational excellence through continuous improvement. Combining insights from both methodologies enables a comprehensive approach to enhancing productivity and organizational health.

Comparison Table

| Aspect | Organizational Network Analysis (ONA) | Lean Management |

|---|---|---|

| Definition | Analyzes relationships and communication patterns within an organization. | Optimizes processes by eliminating waste and improving efficiency. |

| Focus Area | Interpersonal networks and collaboration. | Process flow and operational efficiency. |

| Goal | Enhance knowledge sharing and decision-making. | Maximize value and minimize waste. |

| Tools | Network mapping, social graph analysis. | Value stream mapping, Kaizen, 5S. |

| Application | Improves organizational culture and collaboration. | Streamlines operations and reduces costs. |

| Output | Identification of key influencers and communication bottlenecks. | Standardized workflows and continuous improvement cycles. |

| Industry Use | HR, Change Management, Knowledge Management. | Manufacturing, Services, Healthcare. |

Which is better?

Organizational Network Analysis (ONA) excels in identifying informal connections and communication bottlenecks within a company's social structure, enabling targeted interventions to improve collaboration and knowledge flow. Lean Management focuses on streamlining processes, reducing waste, and improving operational efficiency through continuous improvement methodologies such as Kaizen and Just-In-Time production. Choosing between ONA and Lean Management depends on whether the primary goal is enhancing interpersonal dynamics or optimizing process workflows for organizational performance.

Connection

Organizational Network Analysis (ONA) reveals communication patterns and collaboration dynamics within a company, enabling lean management to identify inefficiencies and streamline processes effectively. By mapping relationships and information flows, ONA supports lean principles by highlighting bottlenecks and underutilized resources that hinder operational excellence. Integrating ONA data empowers lean management strategies to optimize workflow, enhance team coordination, and drive continuous improvement initiatives.

Key Terms

Lean Management:

Lean Management emphasizes waste reduction, continuous improvement, and value creation by streamlining processes and enhancing workflow efficiency. It relies on tools like value stream mapping and Kaizen to identify bottlenecks and foster a culture of employee engagement and empowerment. Discover how Lean Management can transform your organization by driving operational excellence and sustainable growth.

Value Stream Mapping

Lean management emphasizes eliminating waste and optimizing processes through Value Stream Mapping (VSM) to enhance efficiency and deliver maximum customer value. Organizational Network Analysis (ONA) complements VSM by revealing informal relationships and communication flows that impact process performance and collaboration within the value stream. Explore how integrating VSM with ONA can drive deeper insights and more effective value stream improvements.

Continuous Improvement (Kaizen)

Lean management emphasizes continuous improvement (Kaizen) by streamlining processes, reducing waste, and enhancing value through standardized workflows and employee empowerment. Organizational network analysis (ONA) identifies key communication patterns and informal relationships to strengthen collaboration and knowledge sharing, crucial for sustaining Kaizen initiatives. Explore how integrating Lean principles with ONA insights can amplify continuous improvement outcomes.

Source and External Links

What is Lean Management? | Definition from TechTarget - Lean management is an approach focused on continuous improvement, eliminating waste, and creating value for the customer by optimizing resources and workflows, rooted in the Toyota production system principles.

What is a Lean Management System? - Lean Enterprise Academy - A lean management system makes line managers responsible for performance and improvement simultaneously, emphasizing problem-solving at all organizational levels through routines, KPIs, visualization, and structured leadership.

Definition, tools and advantages of Lean Management - Lean management optimizes processes by reducing non-value-added tasks and ensuring smooth workflows and traction systems that respond to actual demand, promoting continuous improvement with involvement from all employees.

dowidth.com

dowidth.com