Digital lean transformation integrates cutting-edge technology and lean principles to drive efficiency and reduce waste across business processes, enhancing agility and customer value. Continuous improvement programs focus on iterative, incremental enhancements through employee engagement and systematic problem-solving methodologies like Kaizen and Six Sigma. Explore how combining these approaches can accelerate organizational performance and innovation.

Why it is important

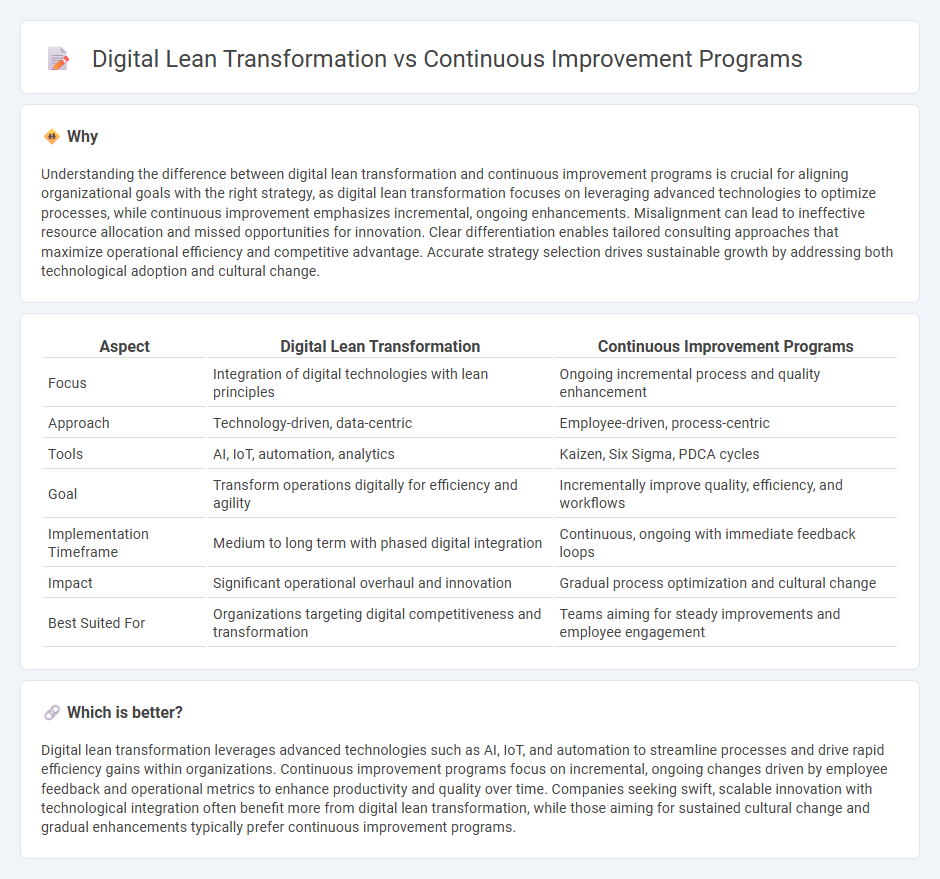

Understanding the difference between digital lean transformation and continuous improvement programs is crucial for aligning organizational goals with the right strategy, as digital lean transformation focuses on leveraging advanced technologies to optimize processes, while continuous improvement emphasizes incremental, ongoing enhancements. Misalignment can lead to ineffective resource allocation and missed opportunities for innovation. Clear differentiation enables tailored consulting approaches that maximize operational efficiency and competitive advantage. Accurate strategy selection drives sustainable growth by addressing both technological adoption and cultural change.

Comparison Table

| Aspect | Digital Lean Transformation | Continuous Improvement Programs |

|---|---|---|

| Focus | Integration of digital technologies with lean principles | Ongoing incremental process and quality enhancement |

| Approach | Technology-driven, data-centric | Employee-driven, process-centric |

| Tools | AI, IoT, automation, analytics | Kaizen, Six Sigma, PDCA cycles |

| Goal | Transform operations digitally for efficiency and agility | Incrementally improve quality, efficiency, and workflows |

| Implementation Timeframe | Medium to long term with phased digital integration | Continuous, ongoing with immediate feedback loops |

| Impact | Significant operational overhaul and innovation | Gradual process optimization and cultural change |

| Best Suited For | Organizations targeting digital competitiveness and transformation | Teams aiming for steady improvements and employee engagement |

Which is better?

Digital lean transformation leverages advanced technologies such as AI, IoT, and automation to streamline processes and drive rapid efficiency gains within organizations. Continuous improvement programs focus on incremental, ongoing changes driven by employee feedback and operational metrics to enhance productivity and quality over time. Companies seeking swift, scalable innovation with technological integration often benefit more from digital lean transformation, while those aiming for sustained cultural change and gradual enhancements typically prefer continuous improvement programs.

Connection

Digital lean transformation leverages advanced technologies such as AI, IoT, and data analytics to enhance efficiency and eliminate waste in business processes, directly supporting continuous improvement programs. Continuous improvement relies on ongoing feedback loops and performance metrics, which are amplified by digital tools that provide real-time insights and automation capabilities. Together, these approaches create a synergistic effect that drives sustained operational excellence and agile business growth.

Key Terms

Kaizen

Continuous improvement programs emphasize incremental changes through employee-driven Kaizen events to enhance process efficiency and reduce waste in real-time operations. Digital lean transformation integrates advanced technologies such as IoT, AI, and data analytics to optimize lean principles on a larger scale, driving strategic agility and predictive decision-making. Explore how combining continuous improvement with digital lean can accelerate your organization's operational excellence.

Digitalization

Continuous improvement programs emphasize incremental enhancements in processes to boost efficiency, often relying on employee engagement and traditional lean tools. Digital lean transformation integrates advanced digital technologies such as IoT, AI, and data analytics to fundamentally redesign workflows and accelerate value delivery. Explore how leveraging digitalization can revolutionize lean strategies by visiting our detailed guide.

Value Stream Mapping

Continuous improvement programs emphasize incremental enhancements by systematically identifying inefficiencies and implementing changes within existing workflows, often relying on traditional Value Stream Mapping (VSM) to visualize process flow and pinpoint waste. In contrast, digital lean transformation integrates advanced digital tools and analytics into VSM, enabling real-time data tracking and automation to optimize value streams more dynamically and accurately. Explore how combining these approaches can revolutionize operational efficiency and advance your organization's lean journey.

Source and External Links

Continuous Improvement Program Building: The Ultimate Guide - This guide outlines the life cycle of Continuous Improvement (CI) programs including initiation, planning, implementation, evaluation, and continuous refinement, with clear roles for senior leaders, CI managers, and site champions to ensure success.

Continual improvement process - Wikipedia - Continuous improvement or continual improvement is an ongoing effort to improve products, services, or processes incrementally or by breakthrough, focusing on feedback, efficiency, and evolutionary steps rather than large leaps.

Continuous Improvement Model - ASQ - The continuous improvement model commonly uses the PDCA (Plan-Do-Check-Act) cycle supplemented by methods like Six Sigma and Lean to systematically improve quality, emphasizing employee involvement and incremental improvements over time.

dowidth.com

dowidth.com