Product traceability enables businesses to track the entire lifecycle of goods, from raw materials to final delivery, ensuring transparency and accountability in the supply chain. Quality assurance focuses on maintaining product standards through systematic processes and testing, preventing defects and enhancing customer satisfaction. Explore how integrating traceability with quality assurance can optimize operational efficiency and consumer trust.

Why it is important

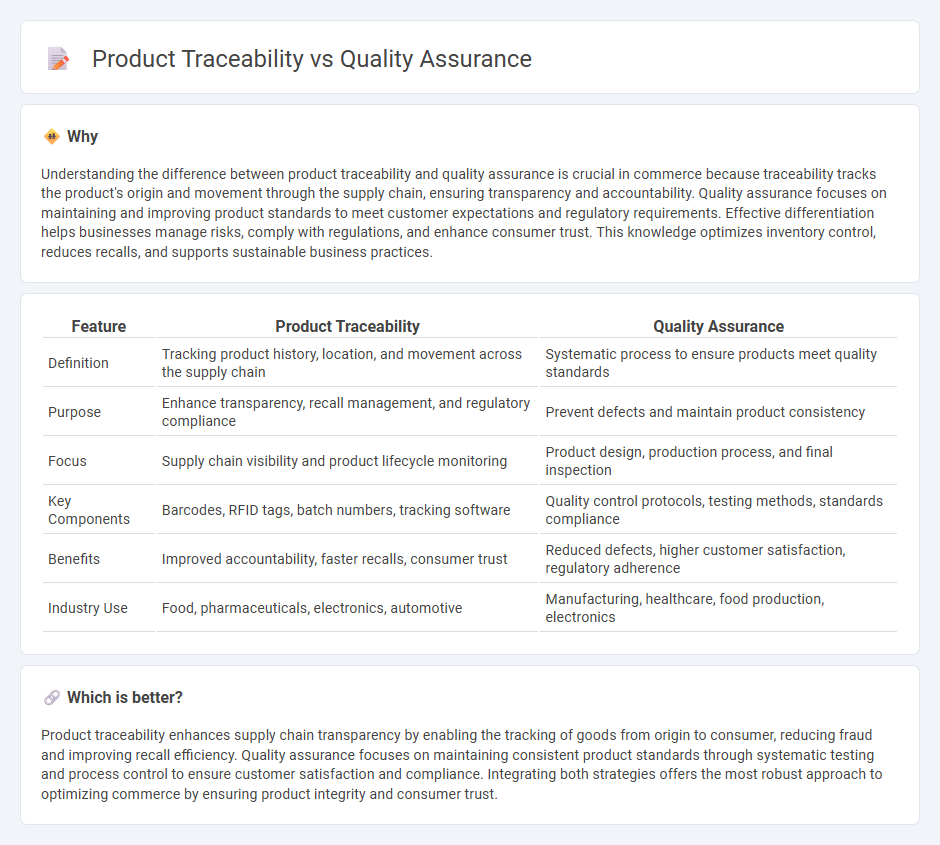

Understanding the difference between product traceability and quality assurance is crucial in commerce because traceability tracks the product's origin and movement through the supply chain, ensuring transparency and accountability. Quality assurance focuses on maintaining and improving product standards to meet customer expectations and regulatory requirements. Effective differentiation helps businesses manage risks, comply with regulations, and enhance consumer trust. This knowledge optimizes inventory control, reduces recalls, and supports sustainable business practices.

Comparison Table

| Feature | Product Traceability | Quality Assurance |

|---|---|---|

| Definition | Tracking product history, location, and movement across the supply chain | Systematic process to ensure products meet quality standards |

| Purpose | Enhance transparency, recall management, and regulatory compliance | Prevent defects and maintain product consistency |

| Focus | Supply chain visibility and product lifecycle monitoring | Product design, production process, and final inspection |

| Key Components | Barcodes, RFID tags, batch numbers, tracking software | Quality control protocols, testing methods, standards compliance |

| Benefits | Improved accountability, faster recalls, consumer trust | Reduced defects, higher customer satisfaction, regulatory adherence |

| Industry Use | Food, pharmaceuticals, electronics, automotive | Manufacturing, healthcare, food production, electronics |

Which is better?

Product traceability enhances supply chain transparency by enabling the tracking of goods from origin to consumer, reducing fraud and improving recall efficiency. Quality assurance focuses on maintaining consistent product standards through systematic testing and process control to ensure customer satisfaction and compliance. Integrating both strategies offers the most robust approach to optimizing commerce by ensuring product integrity and consumer trust.

Connection

Product traceability enhances quality assurance by enabling manufacturers to track each stage of the production process, ensuring defects can be quickly identified and addressed. Detailed traceability records facilitate compliance with industry standards and regulatory requirements, promoting accountability and consistency in product quality. This interconnected system reduces risks of recalls and strengthens consumer trust in the brand's reliability.

Key Terms

Standards Compliance

Quality assurance ensures products meet regulatory standards by implementing systematic processes and controls throughout production. Product traceability highlights the ability to track materials and components from origin to final product, supporting compliance verification and recall management. Explore how integrating quality assurance and traceability enhances standards compliance for manufacturing success.

Supply Chain Visibility

Quality assurance enhances supply chain visibility by ensuring products meet defined standards through systematic inspections and testing at each production stage. Product traceability complements this by tracking the history, application, and location of products within the supply chain, enabling quick identification and resolution of defects or recalls. Discover how integrating quality assurance with product traceability improves supply chain transparency and efficiency.

Certification

Quality assurance ensures that products meet predefined standards through systematic processes and certifications such as ISO 9001, which validate consistency in production and compliance with industry regulations. Product traceability tracks the history, application, and location of materials or products through detailed records, aiding in certification processes by providing verifiable data on product origin and handling. Explore how integrating quality assurance with traceability can enhance certification reliability and operational transparency.

Source and External Links

What is Quality Assurance (QA)? | Definition from TechTarget - Quality assurance (QA) is a systematic process organizations use to ensure a product or service meets specific quality standards, enhancing customer satisfaction, trust, and product quality through methods like failure testing, statistical process control, and total quality management systems.

Quality assurance - Wikipedia - Quality assurance (QA) refers to systematic efforts in manufacturing and service industries to prevent defects and ensure products or services meet contractual and performance expectations, focusing on defect prevention rather than detection.

Quality assurance: A critical ingredient for organizational success - ISO - Quality assurance is a framework that ensures consistency, reliability, and ongoing improvement across an organization's processes, reducing defects early, maintaining standards, complying with regulations, and enhancing competitiveness and profitability.

dowidth.com

dowidth.com