Product traceability enables businesses to track the movement and history of products throughout the supply chain with precision and accuracy. Product recall management involves the organized process of identifying, removing, and disposing of defective or unsafe products from the market to protect consumers and maintain brand integrity. Explore more to understand how efficient traceability systems enhance recall management and ensure consumer safety.

Why it is important

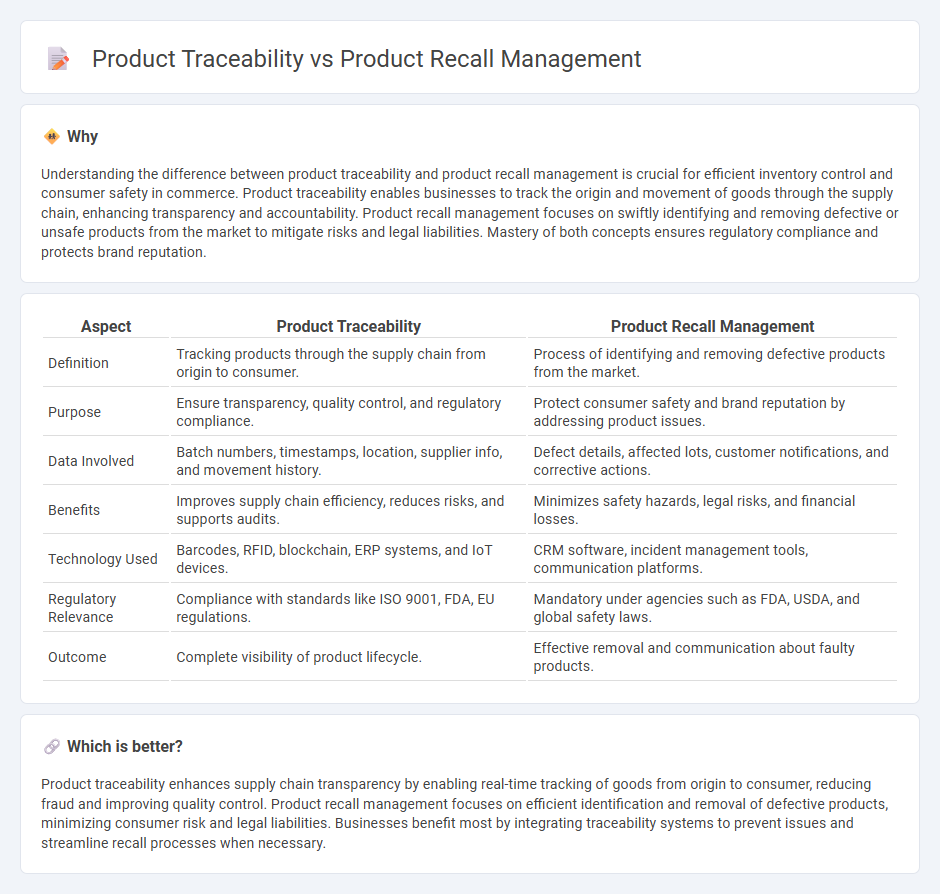

Understanding the difference between product traceability and product recall management is crucial for efficient inventory control and consumer safety in commerce. Product traceability enables businesses to track the origin and movement of goods through the supply chain, enhancing transparency and accountability. Product recall management focuses on swiftly identifying and removing defective or unsafe products from the market to mitigate risks and legal liabilities. Mastery of both concepts ensures regulatory compliance and protects brand reputation.

Comparison Table

| Aspect | Product Traceability | Product Recall Management |

|---|---|---|

| Definition | Tracking products through the supply chain from origin to consumer. | Process of identifying and removing defective products from the market. |

| Purpose | Ensure transparency, quality control, and regulatory compliance. | Protect consumer safety and brand reputation by addressing product issues. |

| Data Involved | Batch numbers, timestamps, location, supplier info, and movement history. | Defect details, affected lots, customer notifications, and corrective actions. |

| Benefits | Improves supply chain efficiency, reduces risks, and supports audits. | Minimizes safety hazards, legal risks, and financial losses. |

| Technology Used | Barcodes, RFID, blockchain, ERP systems, and IoT devices. | CRM software, incident management tools, communication platforms. |

| Regulatory Relevance | Compliance with standards like ISO 9001, FDA, EU regulations. | Mandatory under agencies such as FDA, USDA, and global safety laws. |

| Outcome | Complete visibility of product lifecycle. | Effective removal and communication about faulty products. |

Which is better?

Product traceability enhances supply chain transparency by enabling real-time tracking of goods from origin to consumer, reducing fraud and improving quality control. Product recall management focuses on efficient identification and removal of defective products, minimizing consumer risk and legal liabilities. Businesses benefit most by integrating traceability systems to prevent issues and streamline recall processes when necessary.

Connection

Product traceability enables detailed tracking of a product's history, origin, and journey through the supply chain, which is crucial for effective product recall management. When safety issues or defects arise, companies rely on traceability data to quickly identify affected batches and locations, minimizing consumer risk and financial loss. This integration enhances regulatory compliance and reinforces brand trust by ensuring swift, precise recall execution.

Key Terms

**Product Recall Management:**

Product Recall Management involves identifying, retrieving, and correcting defective or unsafe products from the market to protect consumers and maintain brand reputation. It requires robust tracking systems, clear communication channels, and coordinated logistics to efficiently manage recalls and minimize risks. Discover comprehensive strategies and tools that optimize your product recall management process.

Crisis Communication

Product recall management centers on efficiently withdrawing defective products to protect consumers and brand integrity, while product traceability tracks the lifecycle and movement of products for accountability and transparency. Crisis communication in recall management demands swift, clear messaging to stakeholders and media to mitigate reputational damage, whereas traceability supports accurate information dissemination by providing detailed product histories. Explore effective strategies to integrate recall management and traceability for robust crisis communication.

Reverse Logistics

Product recall management involves the systematic process of identifying, retrieving, and safely disposing or correcting defective products to protect consumers and maintain brand reputation, while product traceability focuses on tracking the movement and history of products through the supply chain for transparency and compliance. In reverse logistics, these functions collaborate to efficiently manage returned products, minimize financial losses, and ensure regulatory adherence by leveraging data from traceability systems to execute targeted recalls. Explore more about how integrating recall management with traceability enhances reverse logistics efficiency and customer safety.

Source and External Links

Strategically Manage Product Recalls | NetSuite - Organizations should assemble a cross-functional recall team, assess risk and scope of the issue, and maintain detailed documentation throughout the recall process to ensure compliance and effective response.

The definitive guide to building a product recall program - CMX1 - Effective recall management involves proactive monitoring for early warning signs, rapid investigation and documentation of issues, and precise identification of all affected products, including specific details like lot numbers and expiration dates.

Product Recall Guide | Handle Issues With Precision - Claimlane - Best practices include creating clear, convenient return policies for customers, tracking all returns and refunds, and maintaining regular communication to keep stakeholders informed throughout the recall process.

dowidth.com

dowidth.com