Product traceability enables precise tracking of goods throughout the supply chain, enhancing transparency and accountability in commerce. Inventory management focuses on optimizing stock levels to reduce costs and meet customer demand efficiently. Explore the differences and benefits of these systems to improve your business operations.

Why it is important

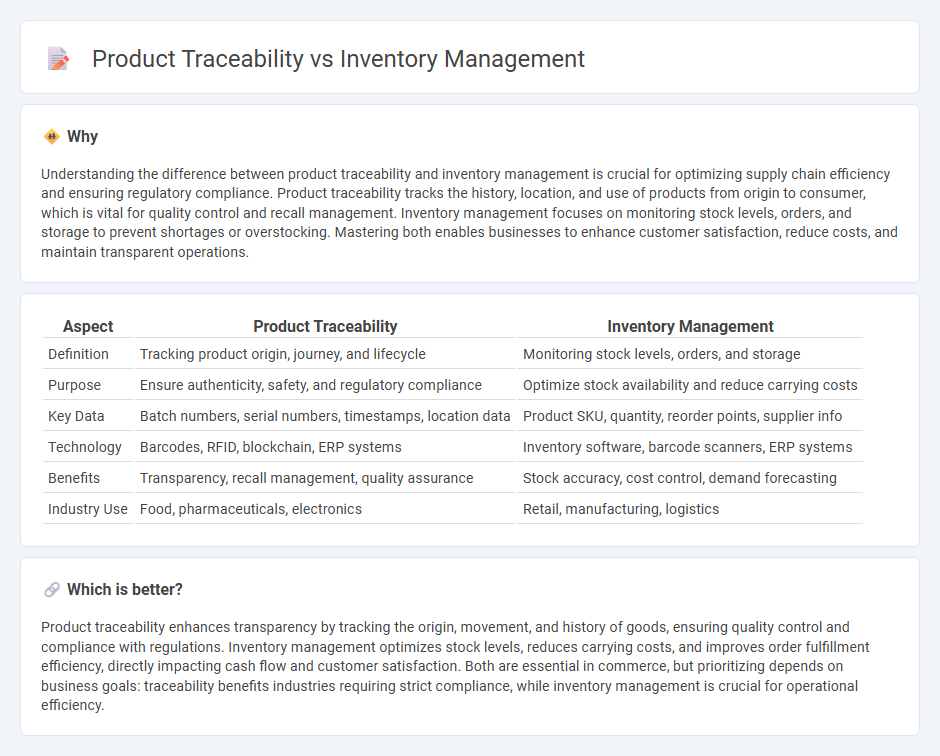

Understanding the difference between product traceability and inventory management is crucial for optimizing supply chain efficiency and ensuring regulatory compliance. Product traceability tracks the history, location, and use of products from origin to consumer, which is vital for quality control and recall management. Inventory management focuses on monitoring stock levels, orders, and storage to prevent shortages or overstocking. Mastering both enables businesses to enhance customer satisfaction, reduce costs, and maintain transparent operations.

Comparison Table

| Aspect | Product Traceability | Inventory Management |

|---|---|---|

| Definition | Tracking product origin, journey, and lifecycle | Monitoring stock levels, orders, and storage |

| Purpose | Ensure authenticity, safety, and regulatory compliance | Optimize stock availability and reduce carrying costs |

| Key Data | Batch numbers, serial numbers, timestamps, location data | Product SKU, quantity, reorder points, supplier info |

| Technology | Barcodes, RFID, blockchain, ERP systems | Inventory software, barcode scanners, ERP systems |

| Benefits | Transparency, recall management, quality assurance | Stock accuracy, cost control, demand forecasting |

| Industry Use | Food, pharmaceuticals, electronics | Retail, manufacturing, logistics |

Which is better?

Product traceability enhances transparency by tracking the origin, movement, and history of goods, ensuring quality control and compliance with regulations. Inventory management optimizes stock levels, reduces carrying costs, and improves order fulfillment efficiency, directly impacting cash flow and customer satisfaction. Both are essential in commerce, but prioritizing depends on business goals: traceability benefits industries requiring strict compliance, while inventory management is crucial for operational efficiency.

Connection

Product traceability and inventory management are intrinsically connected through real-time data tracking, enabling businesses to monitor product movement from origin to final sale. Effective traceability systems improve inventory accuracy, reduce stock discrepancies, and enhance supply chain transparency. This integration supports regulatory compliance and optimizes stock replenishment, minimizing losses and improving customer satisfaction.

Key Terms

**Inventory Management:**

Inventory management involves tracking stock levels, orders, sales, and deliveries to optimize warehouse efficiency and reduce holding costs. It leverages technologies like barcode scanning, RFID, and inventory management software to ensure accurate real-time data on product availability and movement. Explore how advanced inventory management systems can streamline operations, minimize stockouts, and enhance supply chain visibility.

Stock Levels

Inventory management focuses on maintaining optimal stock levels to meet customer demand while minimizing holding costs and avoiding stockouts. Product traceability tracks the origin, movement, and status of products throughout the supply chain, ensuring transparency and facilitating recalls or quality control. Explore the differences and how integrating both can enhance operational efficiency and customer satisfaction.

Reorder Point

Inventory management optimizes stock levels using metrics such as the Reorder Point, ensuring timely replenishment and minimizing stockouts. Product traceability tracks items through the supply chain, enhancing transparency and data accuracy for recall readiness rather than directly influencing reorder timing. Discover how integrating both strategies improves operational efficiency and supply chain resilience.

Source and External Links

What Is Inventory Management? Benefits, Types, & Techniques - Inventory management is the process of tracking and controlling goods flow through demand planning, ordering, delivery, storage, sale, reviewing, and replenishment to optimize inventory and supply chain efficiency.

Inventory Management: How it Works and Tools (2025) - Shopify - Inventory management oversees goods flow within a business using techniques such as economic order quantity, demand planning, RFID, barcodes, and just-in-time to improve accuracy and cash flow.

Inventory Management Guide + Methods & Examples - Extensiv - Inventory management methods include spreadsheets, automated inventory systems, ERP software, and multichannel tracking to ensure accurate inventory control and real-time updates across multiple platforms.

dowidth.com

dowidth.com