On-demand warehousing offers flexible storage solutions by allowing businesses to rent warehouse space as needed, optimizing inventory management and reducing fixed costs. Cross-docking streamlines the supply chain by transferring goods directly from inbound to outbound transportation without long-term storage, accelerating delivery times and lowering inventory holding expenses. Explore the advantages and applications of on-demand warehousing versus cross-docking to enhance your logistics strategy.

Why it is important

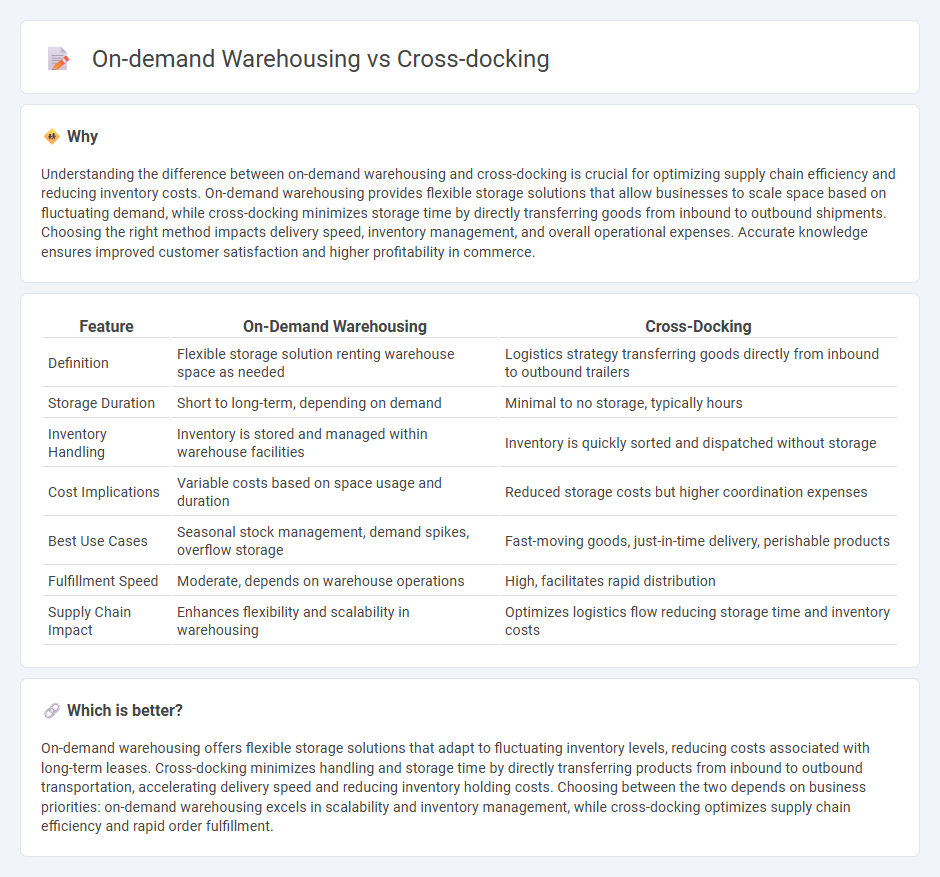

Understanding the difference between on-demand warehousing and cross-docking is crucial for optimizing supply chain efficiency and reducing inventory costs. On-demand warehousing provides flexible storage solutions that allow businesses to scale space based on fluctuating demand, while cross-docking minimizes storage time by directly transferring goods from inbound to outbound shipments. Choosing the right method impacts delivery speed, inventory management, and overall operational expenses. Accurate knowledge ensures improved customer satisfaction and higher profitability in commerce.

Comparison Table

| Feature | On-Demand Warehousing | Cross-Docking |

|---|---|---|

| Definition | Flexible storage solution renting warehouse space as needed | Logistics strategy transferring goods directly from inbound to outbound trailers |

| Storage Duration | Short to long-term, depending on demand | Minimal to no storage, typically hours |

| Inventory Handling | Inventory is stored and managed within warehouse facilities | Inventory is quickly sorted and dispatched without storage |

| Cost Implications | Variable costs based on space usage and duration | Reduced storage costs but higher coordination expenses |

| Best Use Cases | Seasonal stock management, demand spikes, overflow storage | Fast-moving goods, just-in-time delivery, perishable products |

| Fulfillment Speed | Moderate, depends on warehouse operations | High, facilitates rapid distribution |

| Supply Chain Impact | Enhances flexibility and scalability in warehousing | Optimizes logistics flow reducing storage time and inventory costs |

Which is better?

On-demand warehousing offers flexible storage solutions that adapt to fluctuating inventory levels, reducing costs associated with long-term leases. Cross-docking minimizes handling and storage time by directly transferring products from inbound to outbound transportation, accelerating delivery speed and reducing inventory holding costs. Choosing between the two depends on business priorities: on-demand warehousing excels in scalability and inventory management, while cross-docking optimizes supply chain efficiency and rapid order fulfillment.

Connection

On-demand warehousing and cross-docking are connected through their shared goal of optimizing inventory flow and reducing storage costs in commerce logistics. On-demand warehousing provides flexible, temporary storage solutions that complement cross-docking operations by enabling rapid transfer of goods without long-term inventory holding. This integration enhances supply chain efficiency, reduces lead times, and improves responsiveness to fluctuating market demands.

Key Terms

Inventory Management

Cross-docking streamlines inventory management by minimizing storage time and accelerating product flow directly from supplier to customer, reducing holding costs and inventory risks. On-demand warehousing offers flexible, scalable storage solutions that adapt to fluctuating inventory levels and seasonal demands, optimizing space utilization and enhancing supply chain responsiveness. Explore the benefits and use cases of both strategies to optimize your inventory management approach effectively.

Fulfillment Speed

Cross-docking significantly enhances fulfillment speed by transferring products directly from inbound to outbound shipments without long-term storage, reducing handling time and expediting delivery. On-demand warehousing offers flexible storage solutions but may introduce delays due to inventory management and order processing. Explore the key differences to optimize your supply chain efficiency and fulfillment strategy.

Storage Flexibility

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enabling rapid inventory turnover and reducing the need for long-term warehousing. On-demand warehousing offers storage flexibility by allowing businesses to rent space as needed, scaling capacity up or down based on fluctuating demand and minimizing fixed storage costs. Discover how integrating these strategies can optimize your supply chain storage flexibility and efficiency.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods directly from one transportation mode to another with minimal storage, employing methods like continuous cross docking, consolidation, and de-consolidation to optimize flow and reduce handling costs.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain strategy where inbound goods are quickly transferred to outbound transport with little or no warehouse storage, enabling faster delivery, reduced costs, and optimized inventory control across various industries.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking involves direct transfer of products with minimal storage and includes types such as pre-distribution, post-distribution, continuous, consolidation, and deconsolidation, tailored to different logistical and industry-specific needs.

dowidth.com

dowidth.com