Circular supply chains focus on sustainability by reusing, recycling, and regenerating materials to minimize waste and environmental impact, driving long-term value creation. Agile supply chains prioritize flexibility and rapid response to market changes, enhancing efficiency through real-time data and adaptive processes. Explore the differences between circular and agile supply chains to optimize your business strategy.

Why it is important

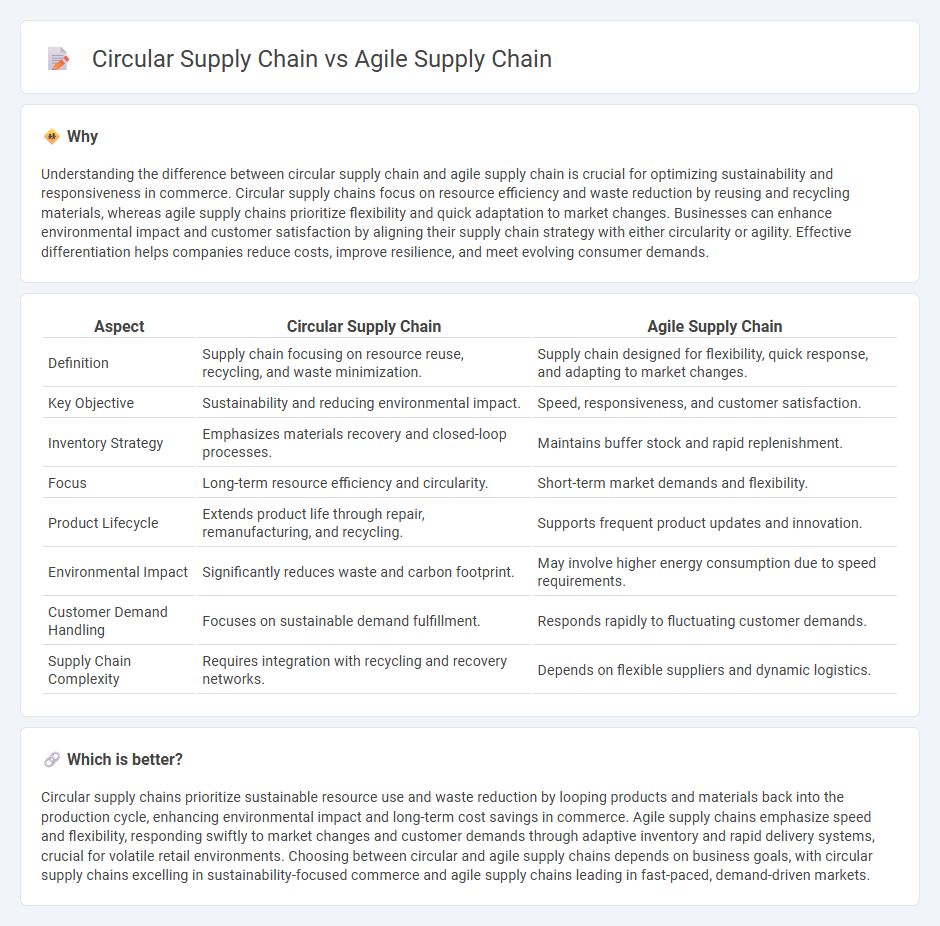

Understanding the difference between circular supply chain and agile supply chain is crucial for optimizing sustainability and responsiveness in commerce. Circular supply chains focus on resource efficiency and waste reduction by reusing and recycling materials, whereas agile supply chains prioritize flexibility and quick adaptation to market changes. Businesses can enhance environmental impact and customer satisfaction by aligning their supply chain strategy with either circularity or agility. Effective differentiation helps companies reduce costs, improve resilience, and meet evolving consumer demands.

Comparison Table

| Aspect | Circular Supply Chain | Agile Supply Chain |

|---|---|---|

| Definition | Supply chain focusing on resource reuse, recycling, and waste minimization. | Supply chain designed for flexibility, quick response, and adapting to market changes. |

| Key Objective | Sustainability and reducing environmental impact. | Speed, responsiveness, and customer satisfaction. |

| Inventory Strategy | Emphasizes materials recovery and closed-loop processes. | Maintains buffer stock and rapid replenishment. |

| Focus | Long-term resource efficiency and circularity. | Short-term market demands and flexibility. |

| Product Lifecycle | Extends product life through repair, remanufacturing, and recycling. | Supports frequent product updates and innovation. |

| Environmental Impact | Significantly reduces waste and carbon footprint. | May involve higher energy consumption due to speed requirements. |

| Customer Demand Handling | Focuses on sustainable demand fulfillment. | Responds rapidly to fluctuating customer demands. |

| Supply Chain Complexity | Requires integration with recycling and recovery networks. | Depends on flexible suppliers and dynamic logistics. |

Which is better?

Circular supply chains prioritize sustainable resource use and waste reduction by looping products and materials back into the production cycle, enhancing environmental impact and long-term cost savings in commerce. Agile supply chains emphasize speed and flexibility, responding swiftly to market changes and customer demands through adaptive inventory and rapid delivery systems, crucial for volatile retail environments. Choosing between circular and agile supply chains depends on business goals, with circular supply chains excelling in sustainability-focused commerce and agile supply chains leading in fast-paced, demand-driven markets.

Connection

Circular supply chains emphasize resource efficiency and waste minimization by recycling and reusing materials, directly aligning with agile supply chains' focus on flexibility and rapid response to market changes. Both supply chain models prioritize sustainability and adaptability, enabling businesses to quickly adjust procurement, production, and distribution processes while minimizing environmental impact. Implementing circular principles within an agile framework enhances supply chain resilience and supports long-term economic and ecological performance.

Key Terms

Flexibility

Agile supply chains emphasize rapid responsiveness and adaptability to changing customer demands and market conditions, leveraging real-time data and cross-functional collaboration to enhance flexibility. Circular supply chains prioritize resource efficiency and sustainability by designing closed-loop systems that enable product reuse, remanufacturing, and waste reduction while maintaining operational adaptability. Discover how integrating these supply chain models can optimize flexibility and sustainability in your operations.

Resource Recovery

Agile supply chains prioritize rapid responsiveness and flexibility to meet fluctuating customer demands, leveraging real-time data and adaptive logistics. Circular supply chains emphasize resource recovery by integrating processes such as recycling, remanufacturing, and waste reduction to promote sustainability and reduce environmental impact. Explore more about how these supply chain models transform resource management and operational efficiency.

Responsiveness

Agile supply chains prioritize responsiveness by rapidly adapting to market changes and fluctuating customer demands through flexible processes and real-time data analytics. Circular supply chains focus on responsiveness by integrating product recovery, remanufacturing, and recycling loops to minimize waste and resource dependency while maintaining supply continuity. Explore how combining agility with circularity enhances both responsiveness and sustainability in modern supply networks.

Source and External Links

Supply Chain Agility: Benefits and Strategies - Oracle - Agile supply chain is the ability to efficiently respond to demand fluctuations by scaling production, using technologies like machine learning in demand planning, and employing just-in-time inventory to reduce costs and improve customer satisfaction.

Agile Supply Chain Management: Meaning, Strategy, & Example - Agile supply chain management is a flexible methodology using iterative cycles, lean procurement, and real-time data to adapt quickly to market changes, with key principles including continuous delivery, shared understanding, and adaptive planning.

Top 10 Benefits of an Agile Supply Chain - Velosio - An agile supply chain enhances operational efficiency and productivity by enabling rapid adjustments based on real-time data, reducing inventory costs, improving order tracking, and adapting fluidly to changing demands through AI and machine learning.

dowidth.com

dowidth.com