Accurate demand forecasting leverages historical sales data and market trends to predict future customer demand, helping retailers optimize inventory levels and reduce stockouts. Supply planning focuses on aligning procurement, production, and distribution processes to ensure the right products are available at the right time, minimizing costs and improving service levels. Explore how integrating demand forecasting and supply planning can transform retail operations and boost profitability.

Why it is important

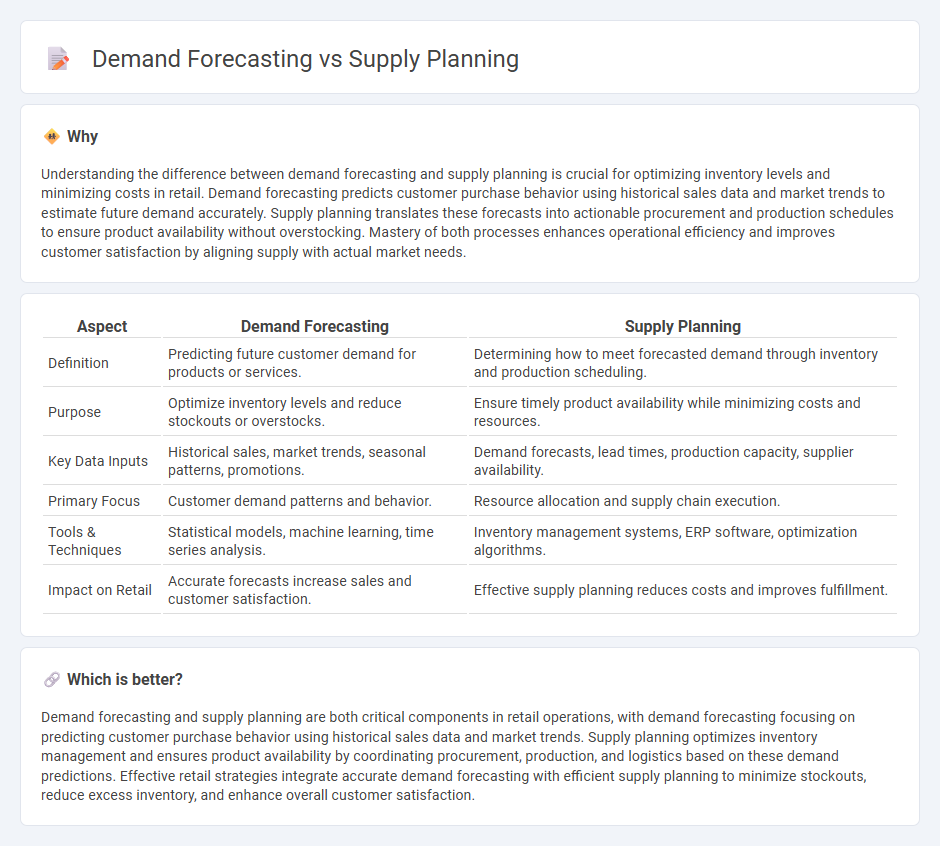

Understanding the difference between demand forecasting and supply planning is crucial for optimizing inventory levels and minimizing costs in retail. Demand forecasting predicts customer purchase behavior using historical sales data and market trends to estimate future demand accurately. Supply planning translates these forecasts into actionable procurement and production schedules to ensure product availability without overstocking. Mastery of both processes enhances operational efficiency and improves customer satisfaction by aligning supply with actual market needs.

Comparison Table

| Aspect | Demand Forecasting | Supply Planning |

|---|---|---|

| Definition | Predicting future customer demand for products or services. | Determining how to meet forecasted demand through inventory and production scheduling. |

| Purpose | Optimize inventory levels and reduce stockouts or overstocks. | Ensure timely product availability while minimizing costs and resources. |

| Key Data Inputs | Historical sales, market trends, seasonal patterns, promotions. | Demand forecasts, lead times, production capacity, supplier availability. |

| Primary Focus | Customer demand patterns and behavior. | Resource allocation and supply chain execution. |

| Tools & Techniques | Statistical models, machine learning, time series analysis. | Inventory management systems, ERP software, optimization algorithms. |

| Impact on Retail | Accurate forecasts increase sales and customer satisfaction. | Effective supply planning reduces costs and improves fulfillment. |

Which is better?

Demand forecasting and supply planning are both critical components in retail operations, with demand forecasting focusing on predicting customer purchase behavior using historical sales data and market trends. Supply planning optimizes inventory management and ensures product availability by coordinating procurement, production, and logistics based on these demand predictions. Effective retail strategies integrate accurate demand forecasting with efficient supply planning to minimize stockouts, reduce excess inventory, and enhance overall customer satisfaction.

Connection

Demand forecasting predicts future customer demand using historical sales data, market trends, and seasonality, enabling accurate inventory management. Supply planning uses these forecasts to allocate resources, schedule production, and manage logistics, ensuring product availability aligns with expected demand. This connection minimizes stockouts and overstock situations, optimizing retail operations and improving customer satisfaction.

Key Terms

Inventory Management

Supply planning centers on coordinating production schedules and inventory levels to meet anticipated customer demand, ensuring optimal stock availability and minimizing carrying costs. Demand forecasting uses historical sales data, market trends, and predictive analytics to estimate future customer demand, guiding inventory replenishment decisions and avoiding stockouts or overstock situations. Explore how integrating effective demand forecasting with supply planning enhances inventory management for improved operational efficiency and customer satisfaction.

Sales Projections

Supply planning optimizes inventory and production schedules based on accurate demand forecasts, ensuring product availability and cost efficiency. Demand forecasting uses historical sales data, market trends, and consumer behavior to predict future sales projections with statistical models and AI algorithms. Explore how integrating advanced sales projections enhances both demand forecasting accuracy and supply planning effectiveness.

Lead Time

Supply planning prioritizes optimizing lead time by coordinating inventory levels, production schedules, and supplier deliveries to meet anticipated demand efficiently. Demand forecasting centers on predicting customer demand patterns using historical data and market trends to inform how much product is needed over a specific lead time. Explore deeper insights on how balancing lead time impacts supply chain performance and responsiveness.

Source and External Links

Supply Planning: Definition, Process, and Best Practices - Supply planning is a process of analyzing demand forecasts, assessing inventory, and coordinating the supply chain to ensure product availability by forecasting demand, determining supply sources, and managing contracts and inventory levels.

Supply Planning in Practice - Aligni - Manufacturing supply planning coordinates procurement, production, and distribution to meet manufacturing demands, involving demand forecasting, inventory analysis, production planning, and materials requirement planning (MRP) to optimize resource flow.

Supply Planning - NetSuite Applications Suite - Oracle Help Center - NetSuite Supply Planning helps planners balance supply and demand by generating supply plans that suggest purchase and work orders based on lead times and expected demand, customizable by planning horizon, scope, and rules.

dowidth.com

dowidth.com