Demand forecasting leverages historical sales data, market trends, and consumer behavior analytics to predict future product demand, enabling retailers to optimize inventory and reduce stockouts. Product lifecycle management (PLM) oversees the entire lifecycle of a product from inception, design, and manufacturing to its end-of-life, ensuring efficient coordination across departments. Discover how integrating demand forecasting with PLM can enhance retail operations and profitability.

Why it is important

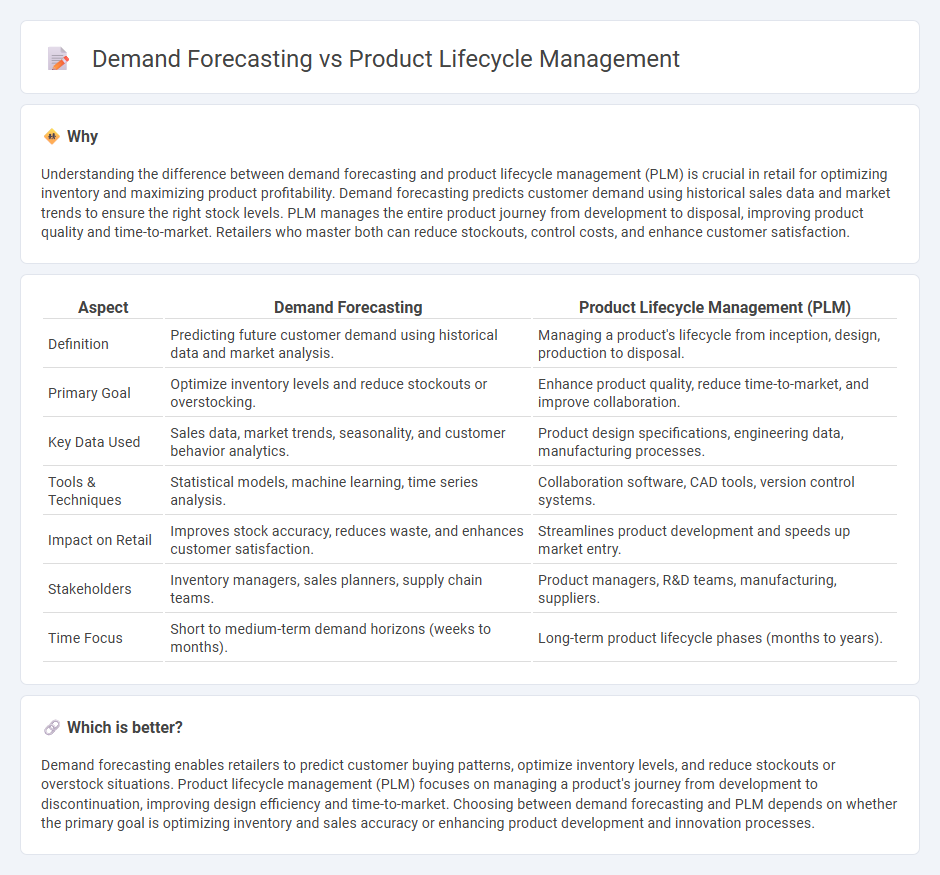

Understanding the difference between demand forecasting and product lifecycle management (PLM) is crucial in retail for optimizing inventory and maximizing product profitability. Demand forecasting predicts customer demand using historical sales data and market trends to ensure the right stock levels. PLM manages the entire product journey from development to disposal, improving product quality and time-to-market. Retailers who master both can reduce stockouts, control costs, and enhance customer satisfaction.

Comparison Table

| Aspect | Demand Forecasting | Product Lifecycle Management (PLM) |

|---|---|---|

| Definition | Predicting future customer demand using historical data and market analysis. | Managing a product's lifecycle from inception, design, production to disposal. |

| Primary Goal | Optimize inventory levels and reduce stockouts or overstocking. | Enhance product quality, reduce time-to-market, and improve collaboration. |

| Key Data Used | Sales data, market trends, seasonality, and customer behavior analytics. | Product design specifications, engineering data, manufacturing processes. |

| Tools & Techniques | Statistical models, machine learning, time series analysis. | Collaboration software, CAD tools, version control systems. |

| Impact on Retail | Improves stock accuracy, reduces waste, and enhances customer satisfaction. | Streamlines product development and speeds up market entry. |

| Stakeholders | Inventory managers, sales planners, supply chain teams. | Product managers, R&D teams, manufacturing, suppliers. |

| Time Focus | Short to medium-term demand horizons (weeks to months). | Long-term product lifecycle phases (months to years). |

Which is better?

Demand forecasting enables retailers to predict customer buying patterns, optimize inventory levels, and reduce stockouts or overstock situations. Product lifecycle management (PLM) focuses on managing a product's journey from development to discontinuation, improving design efficiency and time-to-market. Choosing between demand forecasting and PLM depends on whether the primary goal is optimizing inventory and sales accuracy or enhancing product development and innovation processes.

Connection

Demand forecasting leverages historical sales data and market trends to predict future product demand, enabling efficient inventory control and production planning. Product lifecycle management (PLM) integrates these demand insights to optimize each phase from product development to end-of-life, ensuring timely market entry and phase-out strategies. This connection reduces stockouts and excess inventory, enhancing overall retail profitability and customer satisfaction.

Key Terms

**Product Lifecycle Management:**

Product Lifecycle Management (PLM) integrates data, processes, and business systems to manage a product's journey from conception to disposal, enabling streamlined collaboration and improved decision-making across departments. By centralizing product information, PLM enhances innovation, reduces time-to-market, and supports compliance with industry regulations. Explore how PLM drives efficiency and innovation in product development by learning more about its key features and benefits.

Product Development

Product lifecycle management (PLM) integrates demand forecasting to optimize product development by aligning design, production, and market needs with accurate demand predictions. Effective demand forecasting informs inventory control and resource allocation, reducing time-to-market and enhancing product success rates. Explore how combining PLM with advanced demand forecasting transforms product development efficiency and innovation.

Time-to-Market

Product lifecycle management (PLM) streamlines product development phases to reduce Time-to-Market by integrating design, manufacturing, and supply chain processes. Demand forecasting enhances this by predicting market needs, enabling precise inventory planning and minimizing delays in product availability. Explore how combining PLM and demand forecasting accelerates product launches and improves market responsiveness.

Source and External Links

Build a Product Lifecycle Management Strategy - Product Lifecycle Management (PLM) is a strategic, scalable approach that orchestrates every stage of a product's development, from ideation to design, production, marketing, and long-term support, enabling efficient collaboration and improved product quality across teams involved in the product development process.

Product lifecycle - PLM manages the entire lifecycle of a product from inception through engineering, manufacturing, and disposal, covering key areas like systems engineering, product and portfolio management, design, manufacturing process management, and product data management to improve quality, reduce costs, and optimize product workflows.

What Is PLM Software? | Product Lifecycle Management - PLM software manages information and processes across the full product lifecycle within global supply chains, providing a digital foundation to unify product development and supply chain strategies, enabling faster innovation and improved product design, manufacturing, maintenance, and service.

dowidth.com

dowidth.com