Phantom inventory refers to stock that appears in inventory records but is physically missing due to errors like theft or misplacements, leading to inaccurate supply chain decisions. Excess inventory represents surplus products that exceed current demand, tying up capital and increasing storage costs. Discover more about managing phantom and excess inventory to optimize retail operations and boost profitability.

Why it is important

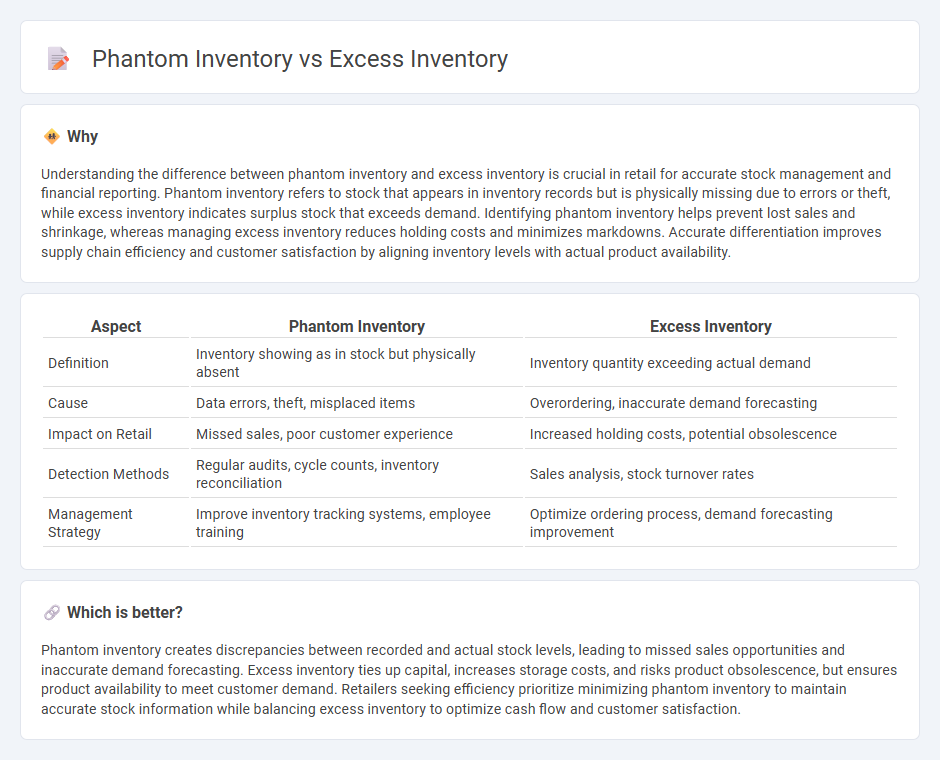

Understanding the difference between phantom inventory and excess inventory is crucial in retail for accurate stock management and financial reporting. Phantom inventory refers to stock that appears in inventory records but is physically missing due to errors or theft, while excess inventory indicates surplus stock that exceeds demand. Identifying phantom inventory helps prevent lost sales and shrinkage, whereas managing excess inventory reduces holding costs and minimizes markdowns. Accurate differentiation improves supply chain efficiency and customer satisfaction by aligning inventory levels with actual product availability.

Comparison Table

| Aspect | Phantom Inventory | Excess Inventory |

|---|---|---|

| Definition | Inventory showing as in stock but physically absent | Inventory quantity exceeding actual demand |

| Cause | Data errors, theft, misplaced items | Overordering, inaccurate demand forecasting |

| Impact on Retail | Missed sales, poor customer experience | Increased holding costs, potential obsolescence |

| Detection Methods | Regular audits, cycle counts, inventory reconciliation | Sales analysis, stock turnover rates |

| Management Strategy | Improve inventory tracking systems, employee training | Optimize ordering process, demand forecasting improvement |

Which is better?

Phantom inventory creates discrepancies between recorded and actual stock levels, leading to missed sales opportunities and inaccurate demand forecasting. Excess inventory ties up capital, increases storage costs, and risks product obsolescence, but ensures product availability to meet customer demand. Retailers seeking efficiency prioritize minimizing phantom inventory to maintain accurate stock information while balancing excess inventory to optimize cash flow and customer satisfaction.

Connection

Phantom inventory occurs when stock records show items available that are physically missing, leading to inaccurate inventory data. Excess inventory results from overestimating demand, often influenced by phantom inventory signals that conceal true stock levels. Both issues disrupt supply chain efficiency and increase holding costs in retail operations.

Key Terms

Stockouts

Excess inventory refers to surplus stock that exceeds demand, while phantom inventory occurs when inventory records show items available but the physical stock is missing. Both issues critically contribute to stockouts, causing lost sales and customer dissatisfaction due to inaccurate inventory visibility. Explore strategies to effectively manage excess and phantom inventory to minimize stockouts and optimize supply chain performance.

Overstock

Overstock represents actual excess inventory physically present in warehouses, often resulting from overproduction, inaccurate demand forecasting, or delayed sales. Phantom inventory, on the other hand, refers to stock recorded in the inventory system but not physically available, caused by errors like theft, misplacement, or data discrepancies. Explore more about how managing overstock effectively can optimize supply chain efficiency and reduce carrying costs.

Inventory accuracy

Excess inventory refers to surplus stock that exceeds demand forecasts, leading to increased holding costs and potential obsolescence, while phantom inventory represents discrepancies between recorded and actual stock levels caused by errors such as theft or miscounts, directly impacting inventory accuracy metrics. Maintaining precise inventory accuracy is crucial for optimizing supply chain efficiency, reducing carrying costs, and improving customer satisfaction through reliable order fulfillment. Discover how advanced inventory management systems can reconcile these issues and enhance overall inventory accuracy.

Source and External Links

What Is Excess Inventory and How to Prevent It? - MRPeasy - Excess inventory is surplus stock exceeding actual demand, leading to cash flow strain, increased costs, and risks such as dead stock; prevention involves accurate forecasting, JIT systems, and efficient inventory management software, while mitigation can include discounts, bundling, and liquidation strategies.

Overstock - Wikipedia - Excess inventory, also called overstock, occurs when stock levels surpass the right quantity for sale and may result from poor demand or stock flow management, causing revenue loss due to tied-up capital and storage costs; typical disposal methods include return, discount sales, or liquidation.

Everything you need to know about excess inventory - Excess inventory arises mainly from misjudged customer demand, shipping delays, or technical issues, and can be identified by low inventory turnover ratios; key prevention methods include demand forecasting software, regular stocktakes, safety stock management, and just-in-time inventory systems.

dowidth.com

dowidth.com