Retail shrinkage analytics focuses on identifying and reducing losses caused by theft, fraud, or errors by analyzing inventory discrepancies and transaction data. Supplier performance management evaluates vendor reliability, product quality, and delivery accuracy to optimize supply chain efficiency and reduce costs. Explore how integrating these approaches can enhance overall retail profitability and operational effectiveness.

Why it is important

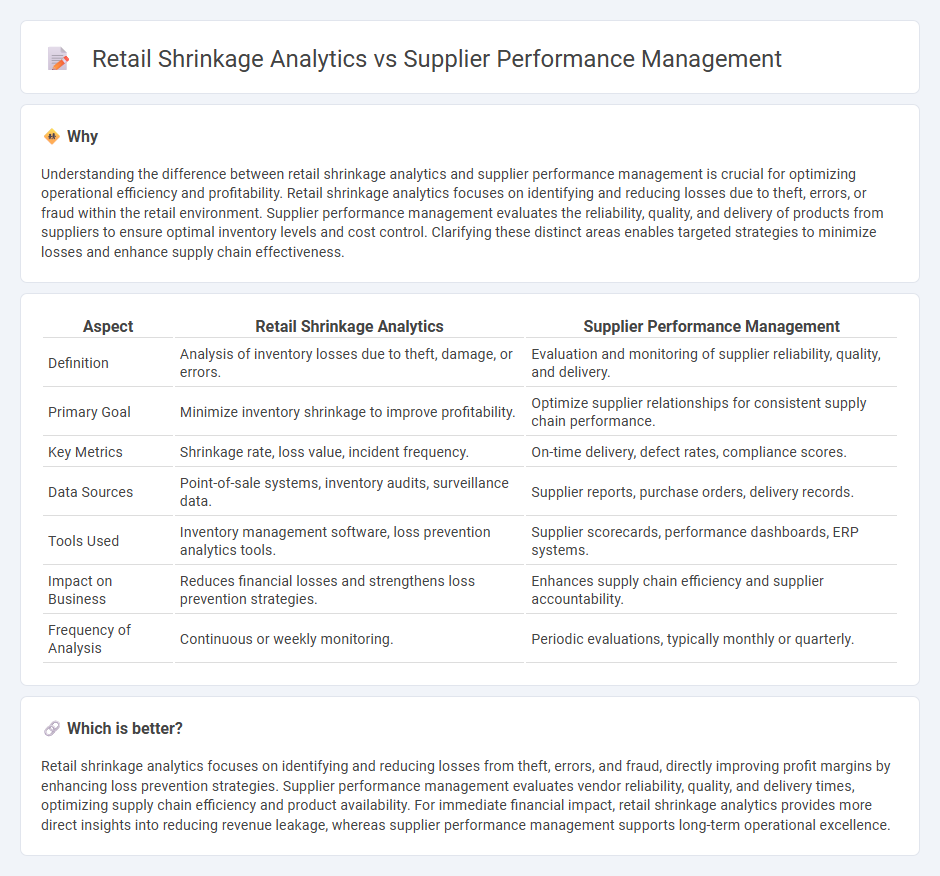

Understanding the difference between retail shrinkage analytics and supplier performance management is crucial for optimizing operational efficiency and profitability. Retail shrinkage analytics focuses on identifying and reducing losses due to theft, errors, or fraud within the retail environment. Supplier performance management evaluates the reliability, quality, and delivery of products from suppliers to ensure optimal inventory levels and cost control. Clarifying these distinct areas enables targeted strategies to minimize losses and enhance supply chain effectiveness.

Comparison Table

| Aspect | Retail Shrinkage Analytics | Supplier Performance Management |

|---|---|---|

| Definition | Analysis of inventory losses due to theft, damage, or errors. | Evaluation and monitoring of supplier reliability, quality, and delivery. |

| Primary Goal | Minimize inventory shrinkage to improve profitability. | Optimize supplier relationships for consistent supply chain performance. |

| Key Metrics | Shrinkage rate, loss value, incident frequency. | On-time delivery, defect rates, compliance scores. |

| Data Sources | Point-of-sale systems, inventory audits, surveillance data. | Supplier reports, purchase orders, delivery records. |

| Tools Used | Inventory management software, loss prevention analytics tools. | Supplier scorecards, performance dashboards, ERP systems. |

| Impact on Business | Reduces financial losses and strengthens loss prevention strategies. | Enhances supply chain efficiency and supplier accountability. |

| Frequency of Analysis | Continuous or weekly monitoring. | Periodic evaluations, typically monthly or quarterly. |

Which is better?

Retail shrinkage analytics focuses on identifying and reducing losses from theft, errors, and fraud, directly improving profit margins by enhancing loss prevention strategies. Supplier performance management evaluates vendor reliability, quality, and delivery times, optimizing supply chain efficiency and product availability. For immediate financial impact, retail shrinkage analytics provides more direct insights into reducing revenue leakage, whereas supplier performance management supports long-term operational excellence.

Connection

Retail shrinkage analytics provides critical insights into inventory losses caused by theft, errors, or fraud, enabling retailers to identify patterns and vulnerabilities in the supply chain. Supplier performance management leverages this data to evaluate and improve supplier reliability, product quality, and delivery accuracy, directly impacting shrinkage rates. Integrating shrinkage analytics with supplier assessments helps optimize inventory control and reduce financial losses in retail operations.

Key Terms

**Supplier Performance Management:**

Supplier Performance Management involves tracking and optimizing vendor reliability, delivery accuracy, and quality compliance to ensure seamless supply chain operations. Key metrics include on-time delivery rates, defect rates, and supplier responsiveness, which directly impact overall procurement efficiency and cost savings. Explore more about how leveraging advanced analytics enhances supplier collaboration and drives operational excellence.

On-time delivery

Supplier performance management emphasizes on-time delivery by tracking supplier reliability and lead time consistency to minimize production delays. Retail shrinkage analytics indirectly relate to on-time delivery by identifying inventory losses caused by delays or supply chain inefficiencies. Explore deeper insights into how on-time delivery impacts both supplier performance and retail shrinkage.

Fill rate

Supplier performance management emphasizes optimizing fill rate to ensure timely and complete order fulfillment, directly impacting inventory availability and sales continuity. Retail shrinkage analytics monitors inventory loss due to theft, errors, or damage, with fill rate analysis helping identify gaps in supply chain efficiency and stock replenishment accuracy. Explore how improving fill rate through these approaches can maximize supply chain effectiveness and minimize revenue loss.

Source and External Links

Ultimate Guide to Supplier Performance Management (SPM) - Supplier Performance Management is a business practice that systematically assesses and manages suppliers' performance by establishing KPIs, collecting data, conducting reviews, providing feedback, collaborating on improvements, monitoring progress, and maintaining documentation.

Supplier Performance Management Metrics and ... - Supplier Performance Management involves setting clear expectations, monitoring and evaluating performance through scorecards, and providing ongoing feedback to drive continuous improvement and strengthen supplier relationships.

How to Optimize Supplier Performance Management (SPM) - Supplier Performance Management tracks metrics such as lead time, on-time delivery, defect rate, quality compliance, order accuracy, contract compliance, cost performance, and responsiveness to improve supplier effectiveness and select optimal partners for business value.

dowidth.com

dowidth.com