Demand forecasting analyzes historical sales data, market trends, and customer behavior to predict future product demand accurately. Replenishment planning uses these demand predictions to optimize inventory levels, ensuring shelves remain stocked without overstocking or stockouts. Discover more about how these strategies enhance retail efficiency and profitability.

Why it is important

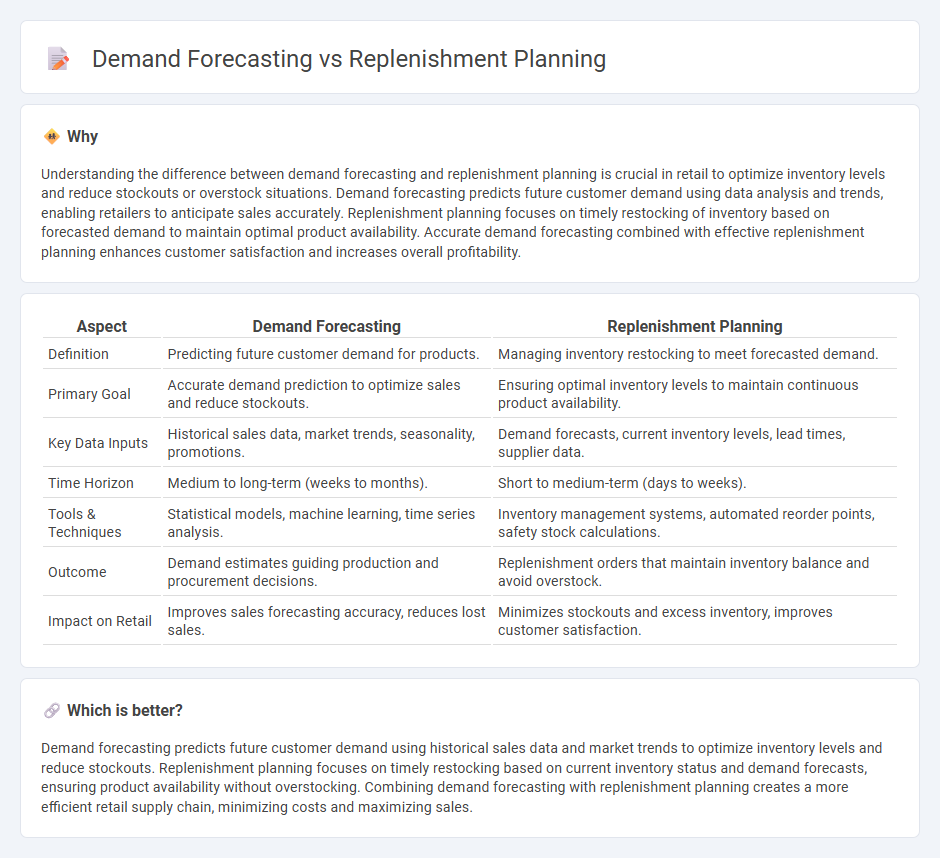

Understanding the difference between demand forecasting and replenishment planning is crucial in retail to optimize inventory levels and reduce stockouts or overstock situations. Demand forecasting predicts future customer demand using data analysis and trends, enabling retailers to anticipate sales accurately. Replenishment planning focuses on timely restocking of inventory based on forecasted demand to maintain optimal product availability. Accurate demand forecasting combined with effective replenishment planning enhances customer satisfaction and increases overall profitability.

Comparison Table

| Aspect | Demand Forecasting | Replenishment Planning |

|---|---|---|

| Definition | Predicting future customer demand for products. | Managing inventory restocking to meet forecasted demand. |

| Primary Goal | Accurate demand prediction to optimize sales and reduce stockouts. | Ensuring optimal inventory levels to maintain continuous product availability. |

| Key Data Inputs | Historical sales data, market trends, seasonality, promotions. | Demand forecasts, current inventory levels, lead times, supplier data. |

| Time Horizon | Medium to long-term (weeks to months). | Short to medium-term (days to weeks). |

| Tools & Techniques | Statistical models, machine learning, time series analysis. | Inventory management systems, automated reorder points, safety stock calculations. |

| Outcome | Demand estimates guiding production and procurement decisions. | Replenishment orders that maintain inventory balance and avoid overstock. |

| Impact on Retail | Improves sales forecasting accuracy, reduces lost sales. | Minimizes stockouts and excess inventory, improves customer satisfaction. |

Which is better?

Demand forecasting predicts future customer demand using historical sales data and market trends to optimize inventory levels and reduce stockouts. Replenishment planning focuses on timely restocking based on current inventory status and demand forecasts, ensuring product availability without overstocking. Combining demand forecasting with replenishment planning creates a more efficient retail supply chain, minimizing costs and maximizing sales.

Connection

Demand forecasting utilizes historical sales data and market trends to predict future customer demand, enabling accurate inventory estimation. Replenishment planning leverages these demand forecasts to schedule timely restocking, minimizing stockouts and overstock situations. Effective integration between demand forecasting and replenishment planning enhances supply chain efficiency, reduces costs, and improves customer satisfaction in retail operations.

Key Terms

Replenishment planning:

Replenishment planning optimizes inventory levels by determining the precise timing and quantity of stock orders to meet customer demand while minimizing holding costs. It relies on real-time sales data, lead times, and safety stock parameters to maintain efficient supply chain flow. Explore how advanced replenishment planning software can enhance operational efficiency and reduce stockouts.

Inventory Levels

Replenishment planning optimizes inventory levels by scheduling timely orders to prevent stockouts and minimize holding costs, ensuring a continuous flow of products. Demand forecasting estimates future customer demand using historical sales data and market trends to guide inventory decisions and production. Explore effective strategies to balance replenishment planning and demand forecasting for optimal inventory management.

Order Frequency

Replenishment planning optimizes order frequency by aligning stock levels with real-time sales data to minimize inventory holding costs and avoid stockouts. Demand forecasting predicts future customer demand using historical sales trends and market analysis, influencing how often orders are placed to meet anticipated needs. Explore more about balancing replenishment planning and demand forecasting to enhance supply chain efficiency.

Source and External Links

5 Critical Steps to a Profitable Replenishment Plan (2025) - Retalon - Replenishment planning is the process of profitably replenishing inventory through optimized timing, quantities, and vendors, aiming to minimize out-of-stock situations, reduce markdowns, cut shipping costs, and manage store transfer costs via best practices including factor mapping, unified infrastructure, advanced analytics, and contingency planning.

Replenishment Planning Explained: What It Is & Why It Matters - Replenishment planning is a strategic approach to maintaining optimal inventory levels by anticipating future stock needs to ensure the supply chain runs efficiently, covering activities such as ordering new stock, transferring inventory, and adapting to changing inventory requirements.

Overview of Oracle Replenishment Planning - Oracle Replenishment Planning supports maintaining optimal inventory at each supply chain node using automated processes for order quantity calculation, demand segmentation, multiechelon replenishment, inventory rebalancing, and analytics to meet service targets and reduce costs.

dowidth.com

dowidth.com