Demand forecasting predicts future customer purchases using historical sales data and market trends to optimize inventory levels, reduce stockouts, and increase profitability. Space planning strategically allocates retail floor space based on product demand and customer behavior to maximize sales per square foot and enhance shopping experience. Explore how integrating demand forecasting with space planning can revolutionize retail efficiency and boost revenue.

Why it is important

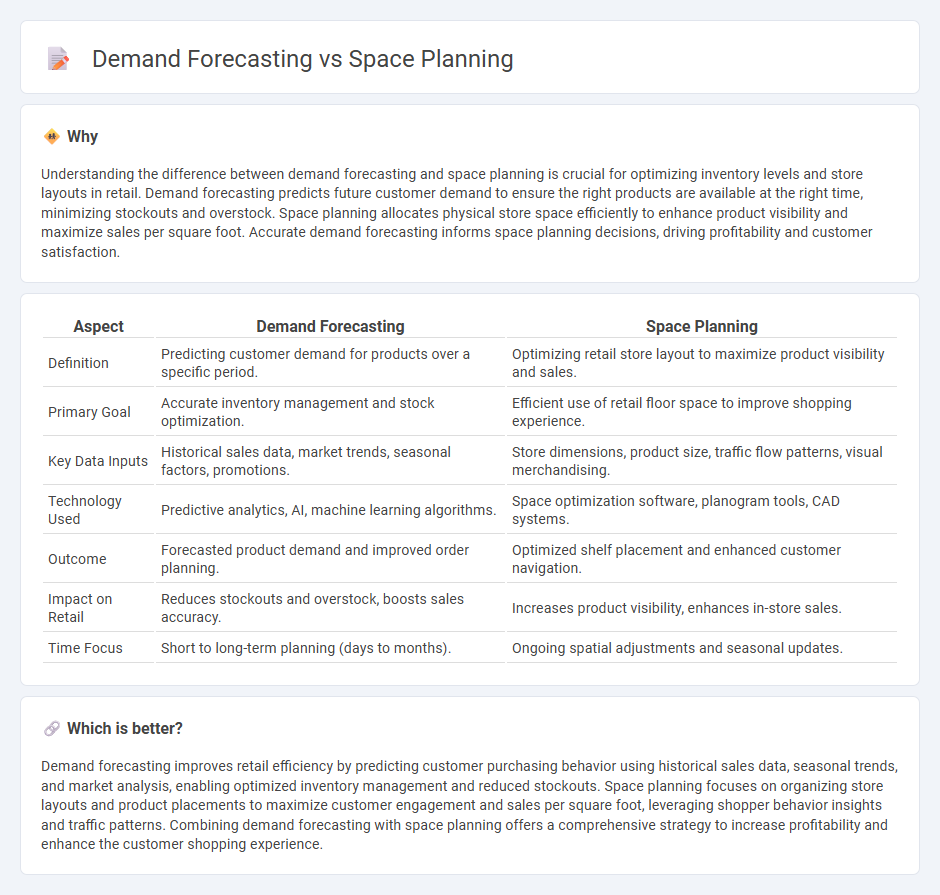

Understanding the difference between demand forecasting and space planning is crucial for optimizing inventory levels and store layouts in retail. Demand forecasting predicts future customer demand to ensure the right products are available at the right time, minimizing stockouts and overstock. Space planning allocates physical store space efficiently to enhance product visibility and maximize sales per square foot. Accurate demand forecasting informs space planning decisions, driving profitability and customer satisfaction.

Comparison Table

| Aspect | Demand Forecasting | Space Planning |

|---|---|---|

| Definition | Predicting customer demand for products over a specific period. | Optimizing retail store layout to maximize product visibility and sales. |

| Primary Goal | Accurate inventory management and stock optimization. | Efficient use of retail floor space to improve shopping experience. |

| Key Data Inputs | Historical sales data, market trends, seasonal factors, promotions. | Store dimensions, product size, traffic flow patterns, visual merchandising. |

| Technology Used | Predictive analytics, AI, machine learning algorithms. | Space optimization software, planogram tools, CAD systems. |

| Outcome | Forecasted product demand and improved order planning. | Optimized shelf placement and enhanced customer navigation. |

| Impact on Retail | Reduces stockouts and overstock, boosts sales accuracy. | Increases product visibility, enhances in-store sales. |

| Time Focus | Short to long-term planning (days to months). | Ongoing spatial adjustments and seasonal updates. |

Which is better?

Demand forecasting improves retail efficiency by predicting customer purchasing behavior using historical sales data, seasonal trends, and market analysis, enabling optimized inventory management and reduced stockouts. Space planning focuses on organizing store layouts and product placements to maximize customer engagement and sales per square foot, leveraging shopper behavior insights and traffic patterns. Combining demand forecasting with space planning offers a comprehensive strategy to increase profitability and enhance the customer shopping experience.

Connection

Demand forecasting uses historical sales data, market trends, and consumer behavior insights to predict future product demand, enabling retailers to allocate inventory efficiently. Space planning leverages these forecasts to optimize store layouts and shelf allocations, ensuring high-demand products receive prime placement that maximizes visibility and sales. Integrating demand forecasting with space planning reduces stockouts and overstocks, enhancing overall retail performance and customer satisfaction.

Key Terms

Planogram

Space planning optimizes retail store layouts by strategically allocating shelf space to enhance product visibility and sales, while demand forecasting predicts customer purchasing behavior using historical data and market trends to guide inventory levels. In the context of planogram development, integrating demand forecasting data allows for more precise product placement, ensuring high-demand items receive premium shelf positioning to maximize turnover. Discover how combining space planning and demand forecasting in your planogram can boost retail performance and customer satisfaction.

Historical Sales Data

Space planning leverages historical sales data to optimize product placement and inventory levels within retail environments, enhancing customer accessibility and maximizing sales potential. Demand forecasting uses the same sales data to predict future product demand, enabling efficient supply chain management and reducing stockouts or overstock situations. Explore how integrating these strategies can improve retail performance and operational efficiency.

Stock Keeping Unit (SKU)

Space planning optimizes the physical layout to maximize product visibility and sales per square foot for each Stock Keeping Unit (SKU), considering shelf space constraints and store traffic flow. Demand forecasting predicts SKU sales volumes using historical sales data, market trends, and seasonality to inform inventory levels and replenishment schedules. Explore how integrating space planning with demand forecasting enhances SKU management and boosts retail efficiency.

Source and External Links

What is Space Planning in Facilities Management? - Space planning is the process of organizing physical space to meet an organization's strategic and operational needs by designing layouts that optimize use, improve workflow, and ensure occupant safety.

Space Planning Basics - introduction for architectural design - Space planning involves organizing and designing spatial arrangements based on the flow, access points, and relationships between adjacent areas, using patterns such as centralized, linear, radial, clustered, or grid organizations.

5 Steps to Effective Space Planning - Effective space planning today focuses on creating dynamic, adaptable work environments that align with business objectives and employee needs, moving beyond cost efficiency to prioritize overall workplace effectiveness.

dowidth.com

dowidth.com