Smart shelf technology utilizes sensors and real-time data analytics to monitor product availability and customer interactions, enhancing inventory accuracy and shopper experience. RFID systems rely on radio-frequency identification tags for seamless tracking and automated stock management, reducing manual labor and shrinkage. Explore how these cutting-edge solutions transform retail operations and boost sales efficiency.

Why it is important

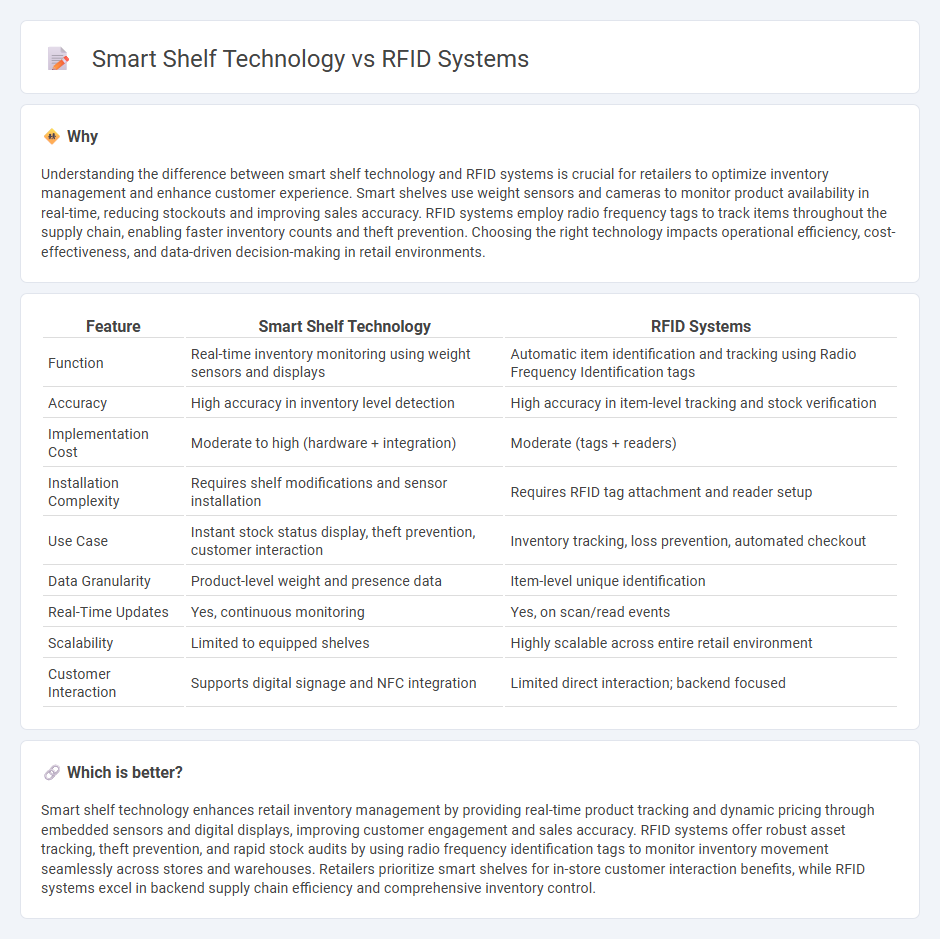

Understanding the difference between smart shelf technology and RFID systems is crucial for retailers to optimize inventory management and enhance customer experience. Smart shelves use weight sensors and cameras to monitor product availability in real-time, reducing stockouts and improving sales accuracy. RFID systems employ radio frequency tags to track items throughout the supply chain, enabling faster inventory counts and theft prevention. Choosing the right technology impacts operational efficiency, cost-effectiveness, and data-driven decision-making in retail environments.

Comparison Table

| Feature | Smart Shelf Technology | RFID Systems |

|---|---|---|

| Function | Real-time inventory monitoring using weight sensors and displays | Automatic item identification and tracking using Radio Frequency Identification tags |

| Accuracy | High accuracy in inventory level detection | High accuracy in item-level tracking and stock verification |

| Implementation Cost | Moderate to high (hardware + integration) | Moderate (tags + readers) |

| Installation Complexity | Requires shelf modifications and sensor installation | Requires RFID tag attachment and reader setup |

| Use Case | Instant stock status display, theft prevention, customer interaction | Inventory tracking, loss prevention, automated checkout |

| Data Granularity | Product-level weight and presence data | Item-level unique identification |

| Real-Time Updates | Yes, continuous monitoring | Yes, on scan/read events |

| Scalability | Limited to equipped shelves | Highly scalable across entire retail environment |

| Customer Interaction | Supports digital signage and NFC integration | Limited direct interaction; backend focused |

Which is better?

Smart shelf technology enhances retail inventory management by providing real-time product tracking and dynamic pricing through embedded sensors and digital displays, improving customer engagement and sales accuracy. RFID systems offer robust asset tracking, theft prevention, and rapid stock audits by using radio frequency identification tags to monitor inventory movement seamlessly across stores and warehouses. Retailers prioritize smart shelves for in-store customer interaction benefits, while RFID systems excel in backend supply chain efficiency and comprehensive inventory control.

Connection

Smart shelf technology integrates RFID systems to enhance inventory management by using RFID tags embedded in products for real-time tracking and stock accuracy. This connection allows retailers to automatically monitor shelf levels, reduce out-of-stock situations, and streamline replenishment processes. The synergy between smart shelves and RFID systems improves customer experience through efficient product availability and data-driven retail operations.

Key Terms

Inventory Tracking

RFID systems enable real-time inventory tracking through wireless identification and scanning of tagged items, significantly reducing manual errors and improving stock accuracy. Smart shelf technology integrates weight sensors and RFID to provide continuous monitoring of item levels, triggering automatic reordering and enhancing shelf management. Explore how combining RFID and smart shelves optimizes inventory accuracy and operational efficiency in retail and warehousing.

Real-time Data

RFID systems provide continuous, automatic identification and tracking of items via radio waves, enabling real-time inventory visibility and reducing stockouts. Smart shelf technology integrates weight sensors and RFID readers to deliver precise stock level monitoring and immediate alerts for restocking. Explore how these technologies enhance retail operations through real-time data insights.

Automation

RFID systems enable real-time automated inventory tracking by using radio waves to identify and manage products without manual scanning, significantly reducing human error and labor costs. Smart shelf technology integrates weight sensors and RFID to automatically detect product removal or stock levels, streamlining restocking processes and ensuring shelf accuracy. Explore how these automation solutions transform retail efficiency and inventory management.

Source and External Links

Radio-frequency identification - RFID systems use electromagnetic fields to automatically identify and track tags attached to objects; they consist of a tag, a radio receiver, and a transmitter, and can be passive (powered by the reader) or active (battery-powered) with applications across industries from inventory to livestock identification.

Different Types of RFID Systems - RFID systems are categorized by operating frequency bands: low frequency (LF), high frequency (HF), and ultra-high frequency (UHF), each with trade-offs in read range, data rate, and interaction with materials like metal or liquids; systems are also classified as passive or active based on power source.

What is RFID and how does it work? - There are three main RFID types by frequency--LF (around 125 KHz), HF (typically 13.56 MHz), and UHF (300 MHz to 960 MHz)--plus microwave RFID (at 2.45 GHz); read ranges vary with frequency and power, with active tags able to be read up to hundreds of feet.

dowidth.com

dowidth.com