Assortment planning focuses on selecting the right mix of products to meet customer demand and optimize sales, while inventory management ensures those products are stocked in appropriate quantities to prevent stockouts or excess. Effective retail operations balance these strategies to enhance profitability and customer satisfaction. Explore how integrating assortment planning with inventory management drives retail success.

Why it is important

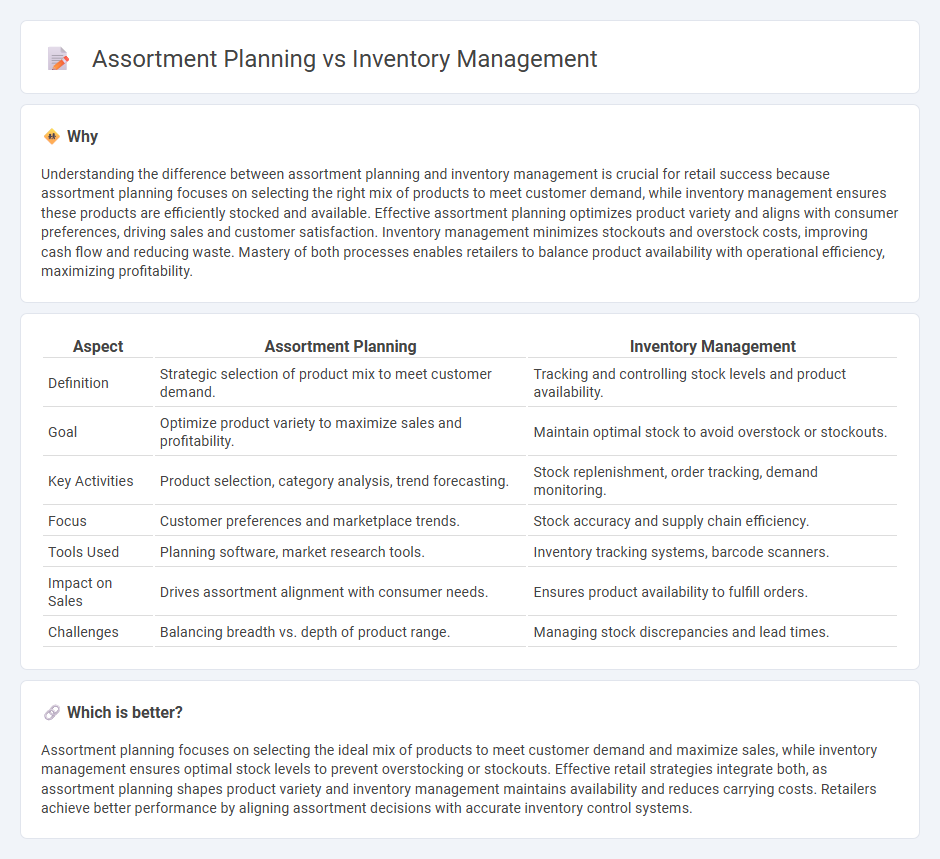

Understanding the difference between assortment planning and inventory management is crucial for retail success because assortment planning focuses on selecting the right mix of products to meet customer demand, while inventory management ensures these products are efficiently stocked and available. Effective assortment planning optimizes product variety and aligns with consumer preferences, driving sales and customer satisfaction. Inventory management minimizes stockouts and overstock costs, improving cash flow and reducing waste. Mastery of both processes enables retailers to balance product availability with operational efficiency, maximizing profitability.

Comparison Table

| Aspect | Assortment Planning | Inventory Management |

|---|---|---|

| Definition | Strategic selection of product mix to meet customer demand. | Tracking and controlling stock levels and product availability. |

| Goal | Optimize product variety to maximize sales and profitability. | Maintain optimal stock to avoid overstock or stockouts. |

| Key Activities | Product selection, category analysis, trend forecasting. | Stock replenishment, order tracking, demand monitoring. |

| Focus | Customer preferences and marketplace trends. | Stock accuracy and supply chain efficiency. |

| Tools Used | Planning software, market research tools. | Inventory tracking systems, barcode scanners. |

| Impact on Sales | Drives assortment alignment with consumer needs. | Ensures product availability to fulfill orders. |

| Challenges | Balancing breadth vs. depth of product range. | Managing stock discrepancies and lead times. |

Which is better?

Assortment planning focuses on selecting the ideal mix of products to meet customer demand and maximize sales, while inventory management ensures optimal stock levels to prevent overstocking or stockouts. Effective retail strategies integrate both, as assortment planning shapes product variety and inventory management maintains availability and reduces carrying costs. Retailers achieve better performance by aligning assortment decisions with accurate inventory control systems.

Connection

Assortment planning and inventory management are closely connected because effective assortment planning determines the optimal mix of products to meet customer demand, while inventory management ensures those products are stocked at the right levels to prevent stockouts or overstock. Accurate demand forecasting and sales data analysis link both processes, enabling retailers to align inventory levels with planned assortments for maximum profitability. Integration of these functions enhances supply chain efficiency, reduces carrying costs, and improves product availability across retail channels.

Key Terms

**Inventory management:**

Inventory management involves overseeing the ordering, storage, and use of products to ensure optimal stock levels, reduce carrying costs, and prevent stockouts. Effective inventory management leverages real-time data analytics and automated replenishment systems to improve accuracy and efficiency in supply chain operations. Discover more strategies to enhance inventory management for business success.

Stock turnover

Inventory management focuses on optimizing stock levels to balance supply and demand, minimizing holding costs while preventing stockouts. Assortment planning strategically selects product varieties to maximize sales and customer satisfaction, directly influencing stock turnover by aligning inventory with market trends. Explore how integrating inventory management and assortment planning can significantly boost stock turnover rates and operational efficiency.

Replenishment

Inventory management focuses on maintaining optimal stock levels to meet demand and avoid overstock or stockouts, ensuring timely replenishment based on accurate demand forecasting. Assortment planning emphasizes selecting the right mix of products to offer, aligning the assortment with customer preferences and seasonal trends, which directly impacts replenishment frequency and quantities. Explore how integrating inventory management and assortment planning enhances replenishment efficiency and boosts overall retail performance.

Source and External Links

What Is Inventory Management? Benefits, Types, & Techniques - Inventory management is the process of tracking and controlling the flow of goods through clear steps like demand planning, ordering, delivery, tracking, sales, review, and replenishment to optimize supply chain efficiency and reduce costs.

Inventory Management: How it Works and Tools (2025) - Shopify - Inventory management involves overseeing and controlling the stock flow with techniques such as economic order quantity (EOQ), demand planning, safety stock alerts, and use of technology like RFID and barcodes to balance inventory levels and improve cash flow.

Inventory Management Guide + Methods & Examples - Extensiv - Inventory management systems ensure optimal stock by organizing sourcing, tracking inventory changes using spreadsheets, automation, ERP software, and managing multichannel sales and warehouses for accurate forecasting and replenishment.

dowidth.com

dowidth.com