Phantom inventory refers to stock that appears in inventory records but does not physically exist due to errors or theft, disrupting accurate demand forecasting and supply chain management. Safety stock is the additional inventory held to prevent stockouts caused by demand variability and supply delays, ensuring continuous product availability. Explore how optimizing phantom inventory and safety stock balances can enhance retail operations and profitability.

Why it is important

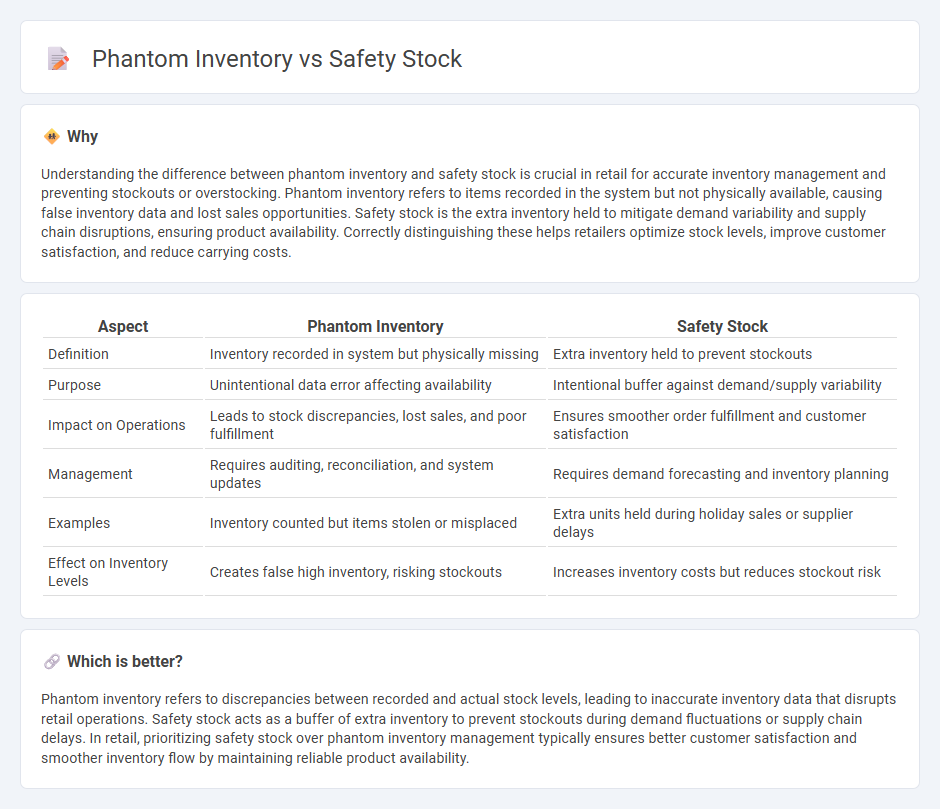

Understanding the difference between phantom inventory and safety stock is crucial in retail for accurate inventory management and preventing stockouts or overstocking. Phantom inventory refers to items recorded in the system but not physically available, causing false inventory data and lost sales opportunities. Safety stock is the extra inventory held to mitigate demand variability and supply chain disruptions, ensuring product availability. Correctly distinguishing these helps retailers optimize stock levels, improve customer satisfaction, and reduce carrying costs.

Comparison Table

| Aspect | Phantom Inventory | Safety Stock |

|---|---|---|

| Definition | Inventory recorded in system but physically missing | Extra inventory held to prevent stockouts |

| Purpose | Unintentional data error affecting availability | Intentional buffer against demand/supply variability |

| Impact on Operations | Leads to stock discrepancies, lost sales, and poor fulfillment | Ensures smoother order fulfillment and customer satisfaction |

| Management | Requires auditing, reconciliation, and system updates | Requires demand forecasting and inventory planning |

| Examples | Inventory counted but items stolen or misplaced | Extra units held during holiday sales or supplier delays |

| Effect on Inventory Levels | Creates false high inventory, risking stockouts | Increases inventory costs but reduces stockout risk |

Which is better?

Phantom inventory refers to discrepancies between recorded and actual stock levels, leading to inaccurate inventory data that disrupts retail operations. Safety stock acts as a buffer of extra inventory to prevent stockouts during demand fluctuations or supply chain delays. In retail, prioritizing safety stock over phantom inventory management typically ensures better customer satisfaction and smoother inventory flow by maintaining reliable product availability.

Connection

Phantom inventory occurs when inventory records show stock availability that does not exist physically, leading to discrepancies in safety stock calculations. Accurate safety stock levels depend on reliable inventory data; phantom inventory inflates perceived stock, resulting in insufficient buffer stock to meet actual demand. Retailers must address phantom inventory issues to maintain optimal safety stock, reducing stockouts and improving customer satisfaction.

Key Terms

Inventory Accuracy

Safety stock represents extra inventory held to prevent stockouts during demand variability, ensuring supply chain continuity. Phantom inventory refers to discrepancies where the recorded stock levels do not match the physical inventory, often due to errors in tracking or theft, impacting inventory accuracy. Explore how optimizing these concepts enhances inventory management and operational efficiency.

Demand Variability

Safety stock acts as a buffer against demand variability by maintaining extra inventory to prevent stockouts during unexpected surges in customer orders. Phantom inventory, on the other hand, arises from system inaccuracies or misreported stock levels, which can mislead demand forecasts and inventory planning. Explore strategies to accurately manage both safety stock and phantom inventory to optimize service levels and reduce holding costs.

Stockouts

Safety stock acts as a buffer inventory to prevent stockouts by absorbing demand variability and supply delays, ensuring continuous product availability. Phantom inventory arises from inaccuracies in inventory records, causing false stock levels that can trigger unexpected stockouts despite physical stock presence. Explore detailed strategies to effectively balance safety stock levels and reduce phantom inventory impacts to minimize stockouts.

Source and External Links

Safety stock - Wikipedia - Safety stock is extra inventory maintained to mitigate the risk of stockouts due to uncertainties in demand, supply, or manufacturing, serving as a buffer to allow business operations to continue smoothly while balancing storage cost and stockout risk.

Safety Stock: What It Is & How to Calculate - NetSuite - Safety stock is extra inventory held to reduce stockout risks caused by supply and demand uncertainties, calculated commonly by formulas considering maximum and average sales and lead times.

What is safety stock? | Definition, Importance, Formula - Zoho - Safety stock serves as insurance inventory against demand spikes, supplier delays, and price fluctuations to ensure continuous order fulfillment even in unpredictable market conditions.

dowidth.com

dowidth.com