Demand forecasting uses historical sales data and market trends to predict future customer demand, enabling retailers to optimize stock levels and reduce excess inventory. Inventory planning focuses on managing stock quantities, reorder points, and safety stock to ensure product availability while minimizing holding costs. Explore the link between demand forecasting and inventory planning to enhance retail operational efficiency.

Why it is important

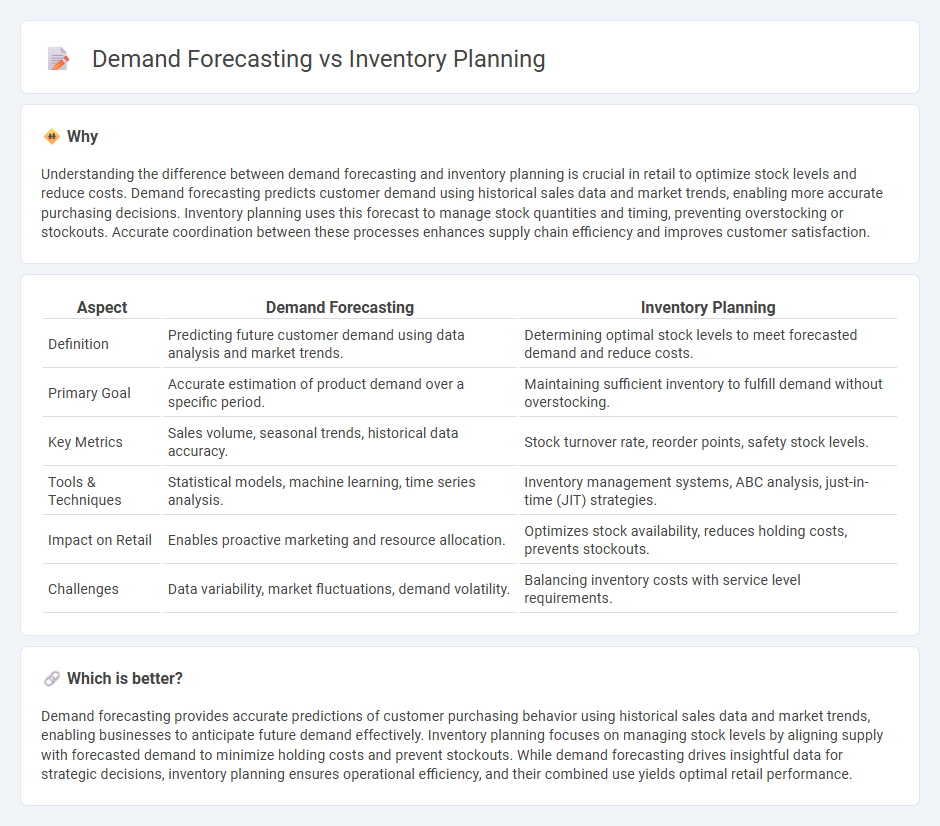

Understanding the difference between demand forecasting and inventory planning is crucial in retail to optimize stock levels and reduce costs. Demand forecasting predicts customer demand using historical sales data and market trends, enabling more accurate purchasing decisions. Inventory planning uses this forecast to manage stock quantities and timing, preventing overstocking or stockouts. Accurate coordination between these processes enhances supply chain efficiency and improves customer satisfaction.

Comparison Table

| Aspect | Demand Forecasting | Inventory Planning |

|---|---|---|

| Definition | Predicting future customer demand using data analysis and market trends. | Determining optimal stock levels to meet forecasted demand and reduce costs. |

| Primary Goal | Accurate estimation of product demand over a specific period. | Maintaining sufficient inventory to fulfill demand without overstocking. |

| Key Metrics | Sales volume, seasonal trends, historical data accuracy. | Stock turnover rate, reorder points, safety stock levels. |

| Tools & Techniques | Statistical models, machine learning, time series analysis. | Inventory management systems, ABC analysis, just-in-time (JIT) strategies. |

| Impact on Retail | Enables proactive marketing and resource allocation. | Optimizes stock availability, reduces holding costs, prevents stockouts. |

| Challenges | Data variability, market fluctuations, demand volatility. | Balancing inventory costs with service level requirements. |

Which is better?

Demand forecasting provides accurate predictions of customer purchasing behavior using historical sales data and market trends, enabling businesses to anticipate future demand effectively. Inventory planning focuses on managing stock levels by aligning supply with forecasted demand to minimize holding costs and prevent stockouts. While demand forecasting drives insightful data for strategic decisions, inventory planning ensures operational efficiency, and their combined use yields optimal retail performance.

Connection

Demand forecasting analyzes historical sales data, market trends, and consumer behavior to predict future product demand in retail. Inventory planning uses these forecasts to optimize stock levels, minimizing overstock and stockouts while ensuring product availability. Accurate demand forecasting directly improves inventory planning, reducing costs and enhancing customer satisfaction.

Key Terms

**Inventory Planning:**

Inventory planning involves strategically determining the optimal quantity and timing of stock replenishment to meet customer demand while minimizing holding costs and avoiding stockouts. It integrates real-time sales data, supply chain lead times, and storage capacity to maintain balanced inventory levels that support operational efficiency and profitability. Explore detailed strategies and tools to enhance your inventory planning for improved business outcomes.

Reorder Point

Inventory planning involves determining the optimal reorder point (ROP) to maintain stock levels and avoid shortages, calculated based on lead time demand and safety stock. Demand forecasting predicts future customer demand using historical sales data, seasonality, and market trends, providing essential input for setting accurate reorder points. Explore detailed strategies to optimize reorder point calculations and improve inventory efficiency.

Stock Keeping Unit (SKU)

Inventory planning revolves around allocating stock levels for each Stock Keeping Unit (SKU) to ensure optimal availability while minimizing holding costs. Demand forecasting predicts future sales volume per SKU using historical data, seasonal trends, and market analysis to guide inventory decisions. Discover how integrating SKU-specific demand forecasts enhances inventory planning accuracy and boosts operational efficiency.

Source and External Links

Inventory Planning for Retail: How to Plan Inventory Levels - Shopify - Inventory planning involves forecasting demand, considering suppliers, setting replenishment plans, tracking inventory, optimizing warehouses, and monitoring/adapting to ensure optimal stock levels and cost control in retail businesses.

Inventory planning: Tips to build a better process | RELEX Solutions - Key inventory planning methods include ABC analysis for prioritizing items by value and sales frequency, and Economic Order Quantity (EOQ) for calculating optimal batch sizes to minimize total inventory costs.

Essential Guide to Inventory Planning | NetSuite - Developing an inventory plan requires forecasting demand using internal and external data, considering factors affecting inventory, ensuring warehouse efficiency, streamlining order processes, and leveraging automation tools to reduce errors and improve accuracy.

dowidth.com

dowidth.com