Demand forecasting leverages historical sales data, market trends, and seasonal variations to predict future product demand accurately, optimizing inventory levels and reducing carrying costs. Stockout analysis identifies patterns and causes of inventory shortages, helping retailers prevent lost sales and improve customer satisfaction. Explore deeper insights into demand forecasting and stockout analysis to enhance retail inventory management.

Why it is important

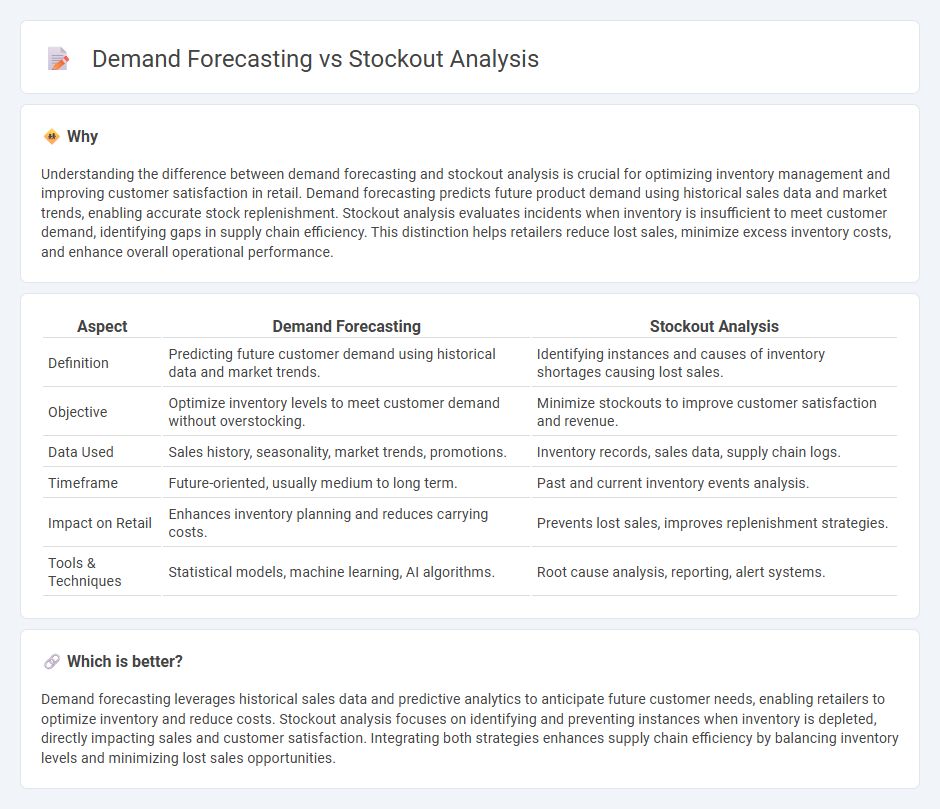

Understanding the difference between demand forecasting and stockout analysis is crucial for optimizing inventory management and improving customer satisfaction in retail. Demand forecasting predicts future product demand using historical sales data and market trends, enabling accurate stock replenishment. Stockout analysis evaluates incidents when inventory is insufficient to meet customer demand, identifying gaps in supply chain efficiency. This distinction helps retailers reduce lost sales, minimize excess inventory costs, and enhance overall operational performance.

Comparison Table

| Aspect | Demand Forecasting | Stockout Analysis |

|---|---|---|

| Definition | Predicting future customer demand using historical data and market trends. | Identifying instances and causes of inventory shortages causing lost sales. |

| Objective | Optimize inventory levels to meet customer demand without overstocking. | Minimize stockouts to improve customer satisfaction and revenue. |

| Data Used | Sales history, seasonality, market trends, promotions. | Inventory records, sales data, supply chain logs. |

| Timeframe | Future-oriented, usually medium to long term. | Past and current inventory events analysis. |

| Impact on Retail | Enhances inventory planning and reduces carrying costs. | Prevents lost sales, improves replenishment strategies. |

| Tools & Techniques | Statistical models, machine learning, AI algorithms. | Root cause analysis, reporting, alert systems. |

Which is better?

Demand forecasting leverages historical sales data and predictive analytics to anticipate future customer needs, enabling retailers to optimize inventory and reduce costs. Stockout analysis focuses on identifying and preventing instances when inventory is depleted, directly impacting sales and customer satisfaction. Integrating both strategies enhances supply chain efficiency by balancing inventory levels and minimizing lost sales opportunities.

Connection

Demand forecasting predicts future customer demand using historical sales data, market trends, and seasonality, enabling retailers to optimize inventory levels. Stockout analysis examines instances of inventory shortages, identifying patterns and causes that disrupt sales and customer satisfaction. Integrating demand forecasting with stockout analysis helps retailers minimize lost sales and improve supply chain efficiency by accurately aligning inventory replenishment with consumer demand.

Key Terms

**Stockout Analysis:**

Stockout analysis identifies the frequency, causes, and impact of inventory shortages on customer satisfaction and sales revenue by examining historical sales data and supply chain disruptions. It highlights critical stockout points that lead to lost sales and helps optimize reorder points and safety stock levels to improve inventory management. Discover how detailed stockout analysis can enhance your operational efficiency and reduce revenue loss.

Service Level

Stockout analysis evaluates inventory shortages that directly impact service levels by tracking the frequency and duration of stockouts, helping businesses identify supply chain inefficiencies. Demand forecasting predicts future customer demand using historical sales data and market trends, enabling companies to optimize inventory levels and maintain desired service levels. Explore how integrating stockout analysis with demand forecasting can enhance service performance and customer satisfaction.

Lost Sales

Stockout analysis evaluates inventory shortages that result in lost sales and customer dissatisfaction, emphasizing the identification of patterns and causes behind stockouts. Demand forecasting predicts future customer demand using historical sales data, market trends, and seasonality to optimize inventory levels and reduce stockout risks. Explore how combining stockout analysis with demand forecasting can enhance sales retention and inventory management efficiency.

Source and External Links

Measuring and Mitigating the Costs of Stockouts - Stockout analysis shows that experiencing stockouts significantly reduces future customer demand, order size, revenue, and conversion rates, illustrating the adverse long-term impacts of stockouts on business performance.

The major causes of stock-outs - Netstock - Stockout analysis includes identifying key causes such as supply chain disruptions, poor demand forecasting, late supplier deliveries, incorrect safety stock levels, and under-ordering, all of which contribute to inventory shortages and lost sales.

Stockouts: How To Calculate Them To Mitigate Production Downtime - Stockout analysis quantifies lost sales by multiplying the number of days out of stock by average units sold per day and unit price, enabling businesses to measure the financial impact and develop strategies to reduce stockouts.

dowidth.com

dowidth.com