Micro fulfillment centers streamline last-mile delivery by utilizing automated systems within urban areas, reducing delivery times and transportation costs. Regional warehouses serve as larger storage hubs that support bulk inventory management and supply chain efficiency across broader geographic zones. Explore how these two fulfillment strategies can transform your retail logistics.

Why it is important

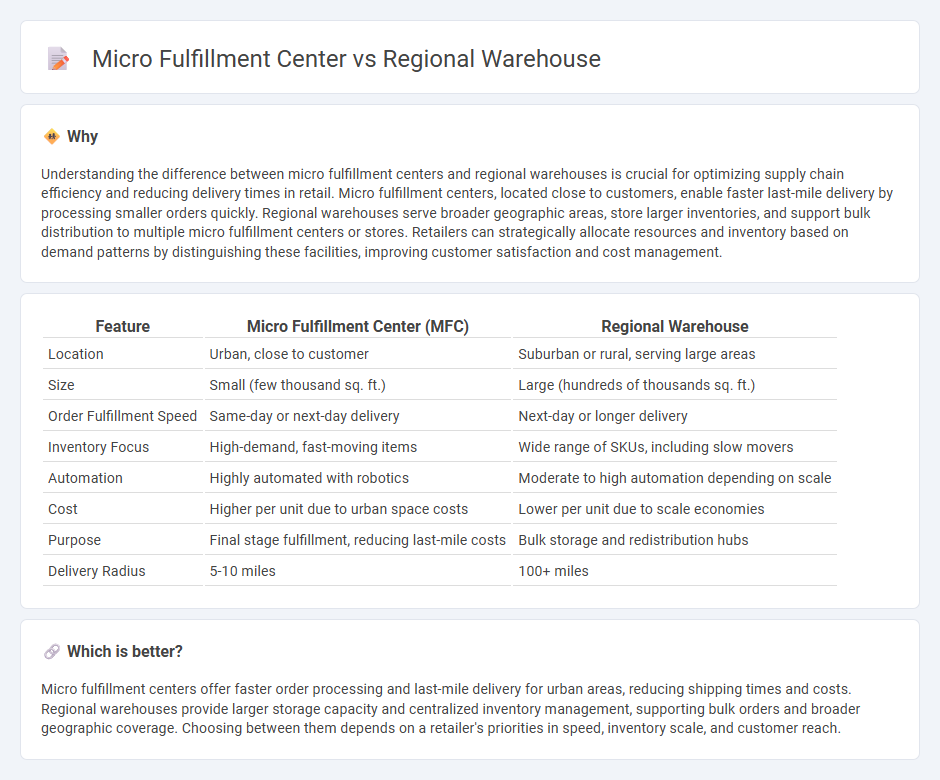

Understanding the difference between micro fulfillment centers and regional warehouses is crucial for optimizing supply chain efficiency and reducing delivery times in retail. Micro fulfillment centers, located close to customers, enable faster last-mile delivery by processing smaller orders quickly. Regional warehouses serve broader geographic areas, store larger inventories, and support bulk distribution to multiple micro fulfillment centers or stores. Retailers can strategically allocate resources and inventory based on demand patterns by distinguishing these facilities, improving customer satisfaction and cost management.

Comparison Table

| Feature | Micro Fulfillment Center (MFC) | Regional Warehouse |

|---|---|---|

| Location | Urban, close to customer | Suburban or rural, serving large areas |

| Size | Small (few thousand sq. ft.) | Large (hundreds of thousands sq. ft.) |

| Order Fulfillment Speed | Same-day or next-day delivery | Next-day or longer delivery |

| Inventory Focus | High-demand, fast-moving items | Wide range of SKUs, including slow movers |

| Automation | Highly automated with robotics | Moderate to high automation depending on scale |

| Cost | Higher per unit due to urban space costs | Lower per unit due to scale economies |

| Purpose | Final stage fulfillment, reducing last-mile costs | Bulk storage and redistribution hubs |

| Delivery Radius | 5-10 miles | 100+ miles |

Which is better?

Micro fulfillment centers offer faster order processing and last-mile delivery for urban areas, reducing shipping times and costs. Regional warehouses provide larger storage capacity and centralized inventory management, supporting bulk orders and broader geographic coverage. Choosing between them depends on a retailer's priorities in speed, inventory scale, and customer reach.

Connection

Micro fulfillment centers and regional warehouses create an integrated supply chain network that enhances retail efficiency by optimizing inventory distribution and reducing delivery times. Regional warehouses store large volumes of goods centrally, supplying micro fulfillment centers located closer to end customers, enabling rapid order processing and last-mile delivery. The seamless coordination between these facilities leverages real-time inventory management systems to balance stock levels and meet fluctuating consumer demand effectively.

Key Terms

Inventory Distribution

Regional warehouses centralize inventory for broad geographic zones, optimizing bulk storage and reducing overall stock duplication, which lowers holding costs. Micro fulfillment centers, strategically located closer to urban demand hubs, enable faster delivery and more precise inventory allocation for high-turnover items. Explore the strategic benefits of these inventory distribution models to enhance supply chain efficiency.

Order Fulfillment Speed

Regional warehouses typically serve larger geographic areas, leading to longer order fulfillment times due to inventory transportation and handling. Micro fulfillment centers, strategically located closer to urban consumers, enable rapid order processing and delivery within hours. Explore how shifting to micro fulfillment centers can significantly enhance your supply chain efficiency and reduce delivery times.

Last-Mile Delivery

Regional warehouses are large storage facilities located strategically to serve broad geographic areas, offering high inventory levels but slower last-mile delivery times. Micro fulfillment centers are smaller, urban-based facilities designed to speed up last-mile delivery by enabling rapid order processing and local distribution. Explore more about how these fulfillment options impact efficiency and customer satisfaction in e-commerce logistics.

Source and External Links

Regional warehouse: Supply chain advantages - Discusses the benefits of regional warehouses, including inventory consolidation, reduced delivery times, cost optimization, and improved availability of goods.

Regional warehouse for smaller distribution zones - Explains how regional warehouses serve as key distribution points for quick and reliable goods distribution within specific regions.

What is Regional Warehouse? - Defines a regional warehouse as a strategically located facility for storing and distributing goods to customers or retail stores within a specific geographic region.

dowidth.com

dowidth.com