Smart shelves use embedded sensors and cameras to monitor product levels and customer interactions in real-time, enhancing inventory accuracy directly on the retail floor. RFID inventory systems rely on radio frequency identification tags and readers to track stock movement throughout the supply chain, providing comprehensive inventory visibility and reducing manual scanning errors. Discover how integrating smart shelves and RFID solutions can transform your retail operations for improved efficiency and customer experience.

Why it is important

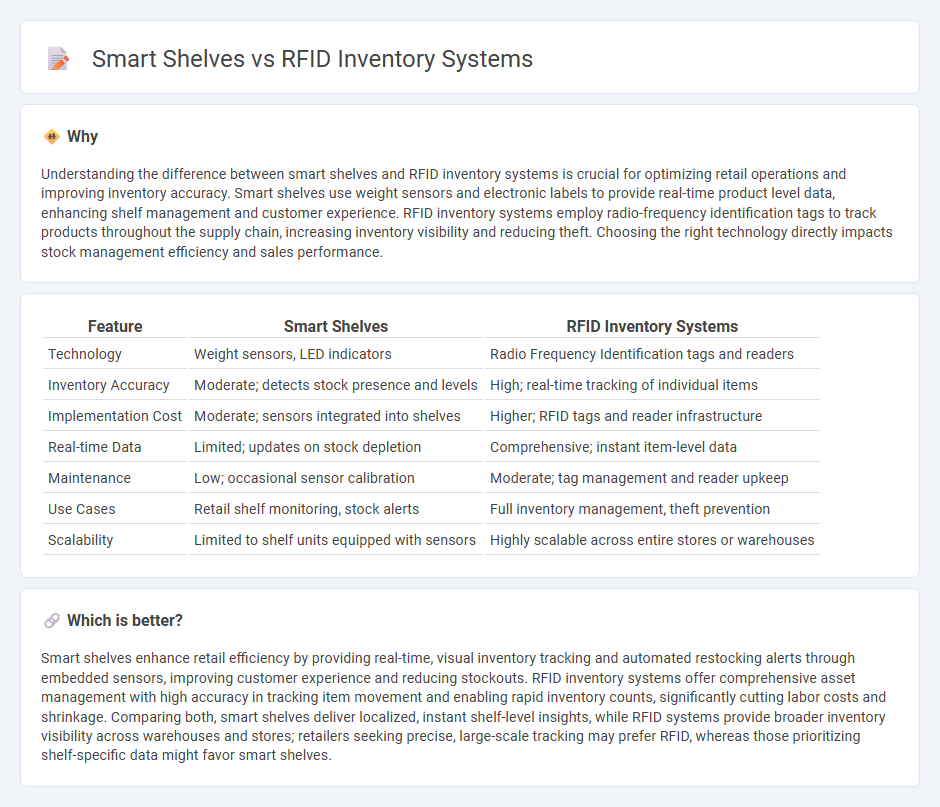

Understanding the difference between smart shelves and RFID inventory systems is crucial for optimizing retail operations and improving inventory accuracy. Smart shelves use weight sensors and electronic labels to provide real-time product level data, enhancing shelf management and customer experience. RFID inventory systems employ radio-frequency identification tags to track products throughout the supply chain, increasing inventory visibility and reducing theft. Choosing the right technology directly impacts stock management efficiency and sales performance.

Comparison Table

| Feature | Smart Shelves | RFID Inventory Systems |

|---|---|---|

| Technology | Weight sensors, LED indicators | Radio Frequency Identification tags and readers |

| Inventory Accuracy | Moderate; detects stock presence and levels | High; real-time tracking of individual items |

| Implementation Cost | Moderate; sensors integrated into shelves | Higher; RFID tags and reader infrastructure |

| Real-time Data | Limited; updates on stock depletion | Comprehensive; instant item-level data |

| Maintenance | Low; occasional sensor calibration | Moderate; tag management and reader upkeep |

| Use Cases | Retail shelf monitoring, stock alerts | Full inventory management, theft prevention |

| Scalability | Limited to shelf units equipped with sensors | Highly scalable across entire stores or warehouses |

Which is better?

Smart shelves enhance retail efficiency by providing real-time, visual inventory tracking and automated restocking alerts through embedded sensors, improving customer experience and reducing stockouts. RFID inventory systems offer comprehensive asset management with high accuracy in tracking item movement and enabling rapid inventory counts, significantly cutting labor costs and shrinkage. Comparing both, smart shelves deliver localized, instant shelf-level insights, while RFID systems provide broader inventory visibility across warehouses and stores; retailers seeking precise, large-scale tracking may prefer RFID, whereas those prioritizing shelf-specific data might favor smart shelves.

Connection

Smart shelves integrate RFID inventory systems to enable real-time tracking of products, improving stock accuracy and reducing out-of-stock instances. RFID sensors embedded in smart shelves automatically scan tagged items, providing retailers with immediate data on inventory levels and product movement. This integration enhances supply chain efficiency and customer experience by enabling automated restocking alerts and seamless inventory management.

Key Terms

Real-time Inventory Tracking

RFID inventory systems leverage radio-frequency identification tags to enable precise real-time inventory tracking by automatically updating stock levels as items move, reducing human error and enhancing supply chain visibility. Smart shelves integrate weight sensors and RFID readers to detect product removal instantly, optimizing shelf replenishment and minimizing stockouts. Discover how combining these technologies can revolutionize inventory accuracy and operational efficiency.

Automated Stock Replenishment

RFID inventory systems enable real-time tracking of stock levels by scanning tags attached to products, providing accurate data for automated stock replenishment and reducing human error. Smart shelves use weight sensors and IoT technology to monitor product quantities and trigger restocking alerts instantly, enhancing efficiency and minimizing out-of-stock situations. Explore the differences in technology and benefits to determine the best automated stock management solution for your business needs.

Item-level Visibility

RFID inventory systems provide real-time item-level visibility through automated tracking of individual products using radio-frequency identification tags, enabling precise stock management and loss prevention. Smart shelves integrate weight sensors and RFID readers to monitor product presence and shelf conditions, enhancing accuracy in stock replenishment and reducing out-of-stock instances. Explore these technologies further to optimize inventory control and improve retail efficiency.

Source and External Links

RFID Inventory Management Systems: Pros & Cons (2024) - Shopify - RFID inventory systems use tags storing data such as SKU, prices, and supply chain history, scanned via RFID readers to provide real-time visibility and loss prevention in retail stores.

Inventory Management with RFID | Track Using RFID Tags - RFID4U - RFID simplifies inventory by tagging items with serial labels and using readers to bulk scan and track goods in warehouses, enabling efficient cycle counts and real-time inventory tracking.

Using RFID for Inventory Management: Pros and Cons - Camcode - RFID systems improve inventory accuracy by up to 13% compared to manual methods, using active or passive tags to automate real-time asset tracking and warehouse inventory counts.

dowidth.com

dowidth.com