Retailers choosing between ship-from-store and central warehouse fulfillment must consider factors such as delivery speed, inventory accuracy, and cost efficiency. Ship-from-store leverages local inventory for faster delivery and reduced transportation costs, while central warehouse fulfillment consolidates stock for better inventory control and scalable operations. Explore how each model impacts your supply chain strategy to optimize retail performance.

Why it is important

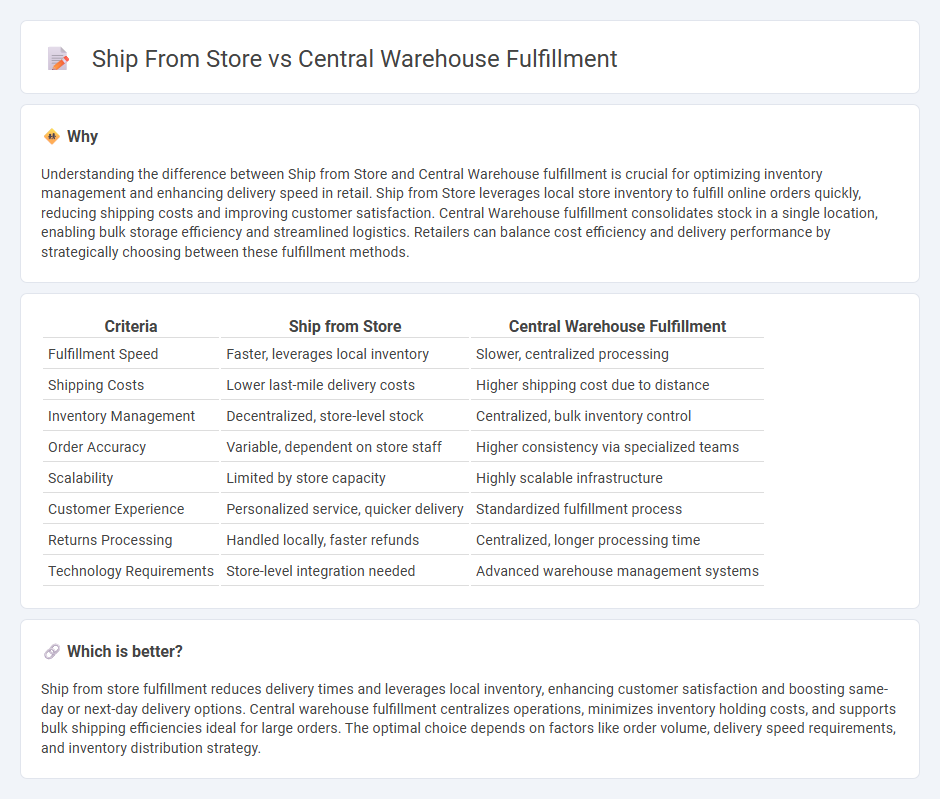

Understanding the difference between Ship from Store and Central Warehouse fulfillment is crucial for optimizing inventory management and enhancing delivery speed in retail. Ship from Store leverages local store inventory to fulfill online orders quickly, reducing shipping costs and improving customer satisfaction. Central Warehouse fulfillment consolidates stock in a single location, enabling bulk storage efficiency and streamlined logistics. Retailers can balance cost efficiency and delivery performance by strategically choosing between these fulfillment methods.

Comparison Table

| Criteria | Ship from Store | Central Warehouse Fulfillment |

|---|---|---|

| Fulfillment Speed | Faster, leverages local inventory | Slower, centralized processing |

| Shipping Costs | Lower last-mile delivery costs | Higher shipping cost due to distance |

| Inventory Management | Decentralized, store-level stock | Centralized, bulk inventory control |

| Order Accuracy | Variable, dependent on store staff | Higher consistency via specialized teams |

| Scalability | Limited by store capacity | Highly scalable infrastructure |

| Customer Experience | Personalized service, quicker delivery | Standardized fulfillment process |

| Returns Processing | Handled locally, faster refunds | Centralized, longer processing time |

| Technology Requirements | Store-level integration needed | Advanced warehouse management systems |

Which is better?

Ship from store fulfillment reduces delivery times and leverages local inventory, enhancing customer satisfaction and boosting same-day or next-day delivery options. Central warehouse fulfillment centralizes operations, minimizes inventory holding costs, and supports bulk shipping efficiencies ideal for large orders. The optimal choice depends on factors like order volume, delivery speed requirements, and inventory distribution strategy.

Connection

Ship from store and central warehouse fulfillment are interconnected through inventory management systems that seamlessly coordinate stock levels across physical stores and central distribution centers. This integration enables retailers to optimize order fulfillment by leveraging both local store inventory and warehouse supply, reducing delivery times and costs. Enhanced visibility and real-time data sharing between these fulfillment methods contribute to improved customer satisfaction and operational efficiency.

Key Terms

Inventory management

Central warehouse fulfillment centralizes inventory in one location, enabling streamlined stock control and bulk order processing that reduces overall handling costs. Ship from store leverages distributed inventory across multiple retail locations, improving delivery speed and reducing last-mile shipping expenses while requiring advanced real-time inventory synchronization. Explore the strategic benefits and challenges of each inventory management approach to optimize your fulfillment operations.

Order routing

Central warehouse fulfillment optimizes inventory management by consolidating stock in a single location, enabling efficient bulk shipping and reduced logistical complexity. Ship from store leverages local store inventories for faster delivery and lower last-mile shipping costs, improving customer satisfaction through proximity. Explore more to understand how advanced order routing algorithms balance speed, cost, and inventory availability for optimized fulfillment strategies.

Delivery speed

Central warehouse fulfillment often results in longer delivery times since products are shipped from a single, centralized location, which may increase transit distances and handling durations. Ship from store leverages local inventory, significantly reducing delivery speed by fulfilling orders from nearby retail locations, enhancing customer satisfaction with faster arrivals. Explore the detailed advantages and operational impacts of both fulfillment methods to optimize your delivery strategy.

Source and External Links

Central Dist. Center: Logistics Guide - A central distribution center consolidates stock, manages inventory, processes orders, and ships products to customers or retail outlets, thereby streamlining shipping and boosting supply chain efficiency.

Fulfillment Center & Warehouse Services: Succeed With Both - A fulfillment center handles all order fulfillment logistics, including receiving inventory, picking, packing, and shipping products directly to customers, often operated by 3PL providers to improve efficiency and customer service.

Fulfillment Center vs. Distribution Center: Essential ... - Fulfillment centers specialize in storing inventory and shipping customer orders, often supporting ecommerce businesses directly with inventory management and order processing, distinct from broader distribution center roles.

dowidth.com

dowidth.com