Smart shelves utilize real-time sensor technology and IoT integration to monitor inventory and customer interactions, enhancing stock visibility and shelf management. Planogram compliance systems analyze visual data to ensure product placement adheres to merchandising standards, optimizing store layout for sales performance. Explore how these technologies revolutionize retail efficiency and customer experience.

Why it is important

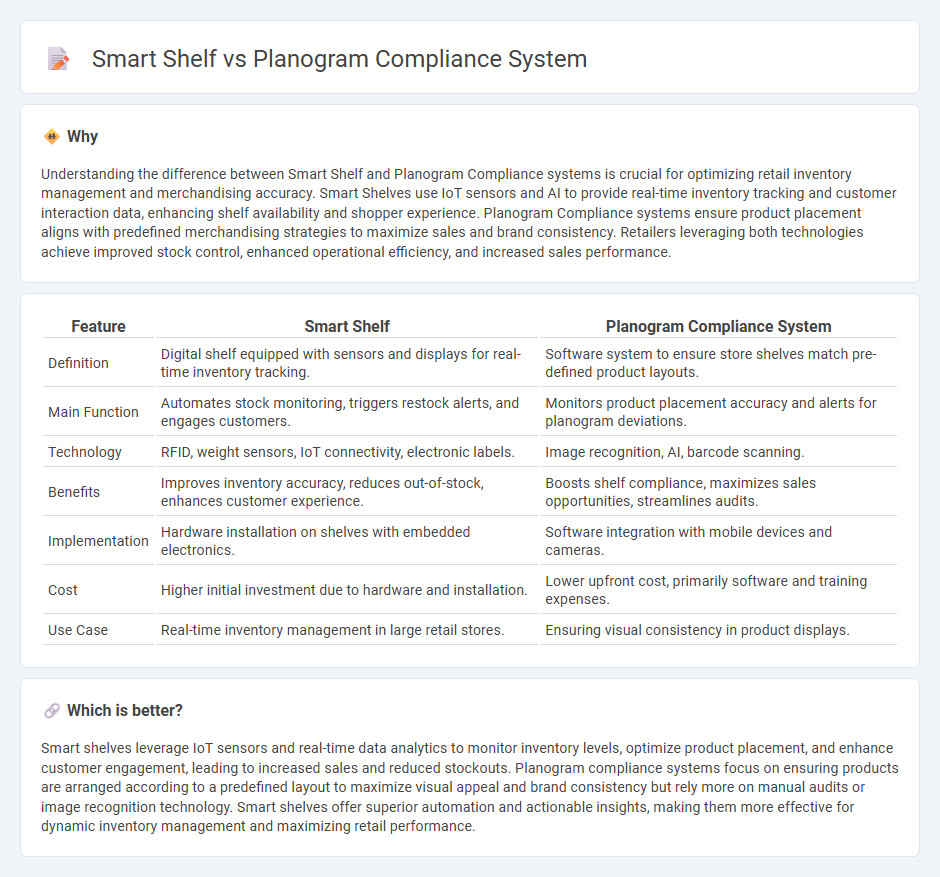

Understanding the difference between Smart Shelf and Planogram Compliance systems is crucial for optimizing retail inventory management and merchandising accuracy. Smart Shelves use IoT sensors and AI to provide real-time inventory tracking and customer interaction data, enhancing shelf availability and shopper experience. Planogram Compliance systems ensure product placement aligns with predefined merchandising strategies to maximize sales and brand consistency. Retailers leveraging both technologies achieve improved stock control, enhanced operational efficiency, and increased sales performance.

Comparison Table

| Feature | Smart Shelf | Planogram Compliance System |

|---|---|---|

| Definition | Digital shelf equipped with sensors and displays for real-time inventory tracking. | Software system to ensure store shelves match pre-defined product layouts. |

| Main Function | Automates stock monitoring, triggers restock alerts, and engages customers. | Monitors product placement accuracy and alerts for planogram deviations. |

| Technology | RFID, weight sensors, IoT connectivity, electronic labels. | Image recognition, AI, barcode scanning. |

| Benefits | Improves inventory accuracy, reduces out-of-stock, enhances customer experience. | Boosts shelf compliance, maximizes sales opportunities, streamlines audits. |

| Implementation | Hardware installation on shelves with embedded electronics. | Software integration with mobile devices and cameras. |

| Cost | Higher initial investment due to hardware and installation. | Lower upfront cost, primarily software and training expenses. |

| Use Case | Real-time inventory management in large retail stores. | Ensuring visual consistency in product displays. |

Which is better?

Smart shelves leverage IoT sensors and real-time data analytics to monitor inventory levels, optimize product placement, and enhance customer engagement, leading to increased sales and reduced stockouts. Planogram compliance systems focus on ensuring products are arranged according to a predefined layout to maximize visual appeal and brand consistency but rely more on manual audits or image recognition technology. Smart shelves offer superior automation and actionable insights, making them more effective for dynamic inventory management and maximizing retail performance.

Connection

Smart shelf technology integrates sensors and RFID to track inventory in real-time, ensuring accurate stock levels and product placement. The Planogram compliance system uses this data to verify that merchandise is displayed according to predefined layouts, optimizing shelf space and enhancing customer experience. Together, these technologies enable retailers to maintain planogram standards efficiently, reduce stockouts, and improve sales performance.

Key Terms

**Planogram compliance system:**

Planogram compliance systems use advanced image recognition and AI technology to ensure that retail shelves match the prescribed product placement, improving inventory accuracy and enhancing visual merchandising effectiveness. These systems provide real-time alerts on stock outs or incorrect product positioning, driving increased sales and reducing shrinkage. Discover how integrating a planogram compliance system can optimize retail shelf management and boost profitability.

Visual Merchandising

Planogram compliance systems ensure product placement accuracy by using shelf-scanning technology and image recognition to verify alignment with predefined layouts, enhancing visual merchandising consistency. Smart shelves integrate weight sensors and RFID tags to monitor inventory in real-time, enabling dynamic product displays and immediate stock replenishment. Explore how these technologies transform retail visual merchandising to maximize customer engagement and sales.

Shelf Auditing

A planogram compliance system uses image recognition and AI to verify product placement against predefined layouts, ensuring accurate shelf auditing and inventory management. Smart shelves leverage weight sensors and RFID technology to monitor stock levels in real-time, providing instant alerts for discrepancies during audits. Discover how integrating these technologies enhances retail shelf auditing efficiency and accuracy.

Source and External Links

What is Planogram Compliance and How to Control it in Retail Store - PlanoHero offers a comprehensive planogram compliance system that integrates planogram creation, communication between HQ and stores, and real-time tracking of layout execution to ensure high-quality shelf layouts and timely correction of errors.

Planogram Compliance 101 - MerchLogix - Planogram compliance systems vary from basic verification of planogram execution to detailed audits involving photo verification and product facing checks, facilitating different levels of compliance accuracy.

Check the Planogram Compliance of your store with the app Ailet - Ailet enables real-time planogram compliance monitoring across retail chains through AI-powered photo recognition, at-shelf instructions, detailed KPI tracking, and BI analytics to link compliance rates with sales performance.

dowidth.com

dowidth.com