Phantom inventory occurs when stock is recorded in the system but is physically missing from shelves, causing discrepancies in retail management and lost sales opportunities. On-shelf availability measures the actual presence of products ready for purchase by customers, directly impacting customer satisfaction and revenue. Explore how minimizing phantom inventory enhances on-shelf availability to boost retail performance.

Why it is important

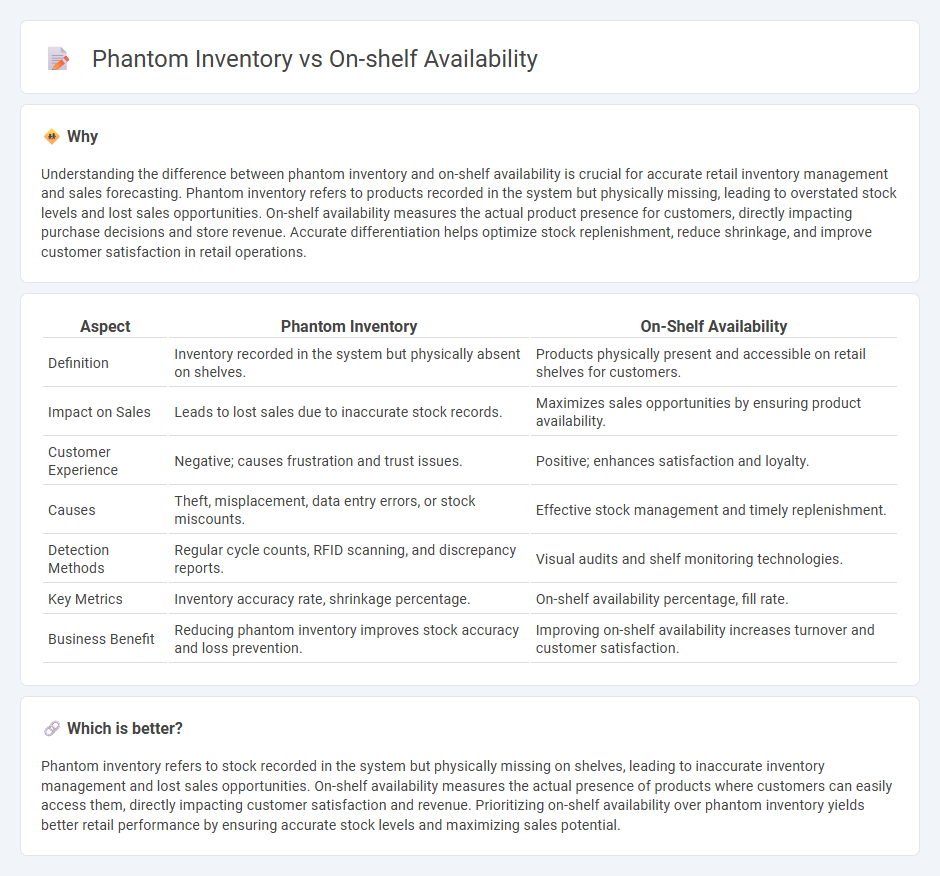

Understanding the difference between phantom inventory and on-shelf availability is crucial for accurate retail inventory management and sales forecasting. Phantom inventory refers to products recorded in the system but physically missing, leading to overstated stock levels and lost sales opportunities. On-shelf availability measures the actual product presence for customers, directly impacting purchase decisions and store revenue. Accurate differentiation helps optimize stock replenishment, reduce shrinkage, and improve customer satisfaction in retail operations.

Comparison Table

| Aspect | Phantom Inventory | On-Shelf Availability |

|---|---|---|

| Definition | Inventory recorded in the system but physically absent on shelves. | Products physically present and accessible on retail shelves for customers. |

| Impact on Sales | Leads to lost sales due to inaccurate stock records. | Maximizes sales opportunities by ensuring product availability. |

| Customer Experience | Negative; causes frustration and trust issues. | Positive; enhances satisfaction and loyalty. |

| Causes | Theft, misplacement, data entry errors, or stock miscounts. | Effective stock management and timely replenishment. |

| Detection Methods | Regular cycle counts, RFID scanning, and discrepancy reports. | Visual audits and shelf monitoring technologies. |

| Key Metrics | Inventory accuracy rate, shrinkage percentage. | On-shelf availability percentage, fill rate. |

| Business Benefit | Reducing phantom inventory improves stock accuracy and loss prevention. | Improving on-shelf availability increases turnover and customer satisfaction. |

Which is better?

Phantom inventory refers to stock recorded in the system but physically missing on shelves, leading to inaccurate inventory management and lost sales opportunities. On-shelf availability measures the actual presence of products where customers can easily access them, directly impacting customer satisfaction and revenue. Prioritizing on-shelf availability over phantom inventory yields better retail performance by ensuring accurate stock levels and maximizing sales potential.

Connection

Phantom inventory refers to stock recorded in the system but physically missing on shelves, directly impacting on-shelf availability by causing discrepancies that lead to stockouts despite apparent inventory levels. Accurate detection and reduction of phantom inventory improve shelf replenishment accuracy, ensuring products are available when customers request them. Retailers rely on real-time inventory tracking and automated shelf-scanning technologies to minimize phantom inventory and enhance on-shelf availability metrics.

Key Terms

Stockout

On-shelf availability measures the percentage of products physically present and ready for purchase on store shelves, directly impacting customer satisfaction and sales. Phantom inventory occurs when the inventory system shows stock available, but the actual product is missing due to theft, misplacement, or errors, leading to unexpected stockouts. Explore how improving inventory accuracy can enhance on-shelf availability and reduce costly stockouts.

Inventory accuracy

On-shelf availability directly reflects the accuracy of inventory records by indicating the actual presence of products for customers, whereas phantom inventory occurs when stock appears in the system but is physically missing, causing discrepancies and lost sales. Accurate inventory management systems reduce phantom inventory instances, improving on-shelf availability and enhancing customer satisfaction. Explore advanced inventory solutions to optimize accuracy and maximize sales potential.

Planogram compliance

Planogram compliance directly impacts on-shelf availability by ensuring products are correctly placed and fully stocked, reducing the occurrence of phantom inventory where items appear available in systems but are missing on shelves. Accurate inventory tracking and shelf replenishment aligned with planograms prevent stockouts and enhance customer satisfaction. Explore detailed strategies to optimize planogram adherence and eliminate phantom inventory challenges.

Source and External Links

How to Improve On Shelf Availability in Retail Stores - Vusion - On-shelf availability (OSA) is a key retail metric measuring how consistently products are available on shelves for purchase, impacting sales, customer satisfaction, and competitive advantage by ensuring efficient inventory management and demand forecasting.

Why On-Shelf Availability Matters - Retail Aware - OSA is critical for increasing sales, building brand loyalty, improving customer satisfaction, and reducing costs by keeping products available and easy to find on store shelves, preventing lost revenue from stockouts.

How Technology is Transforming On-Shelf Availability for FMCG and ... - Netguru - OSA means a product is present on the shelf at the right time and place, and technology like AI and real-time inventory tracking is improving OSA by preventing stockouts and misplaced stock, enhancing shopper convenience and retailer performance.

dowidth.com

dowidth.com