Smart shelves utilize embedded sensors and IoT technology to monitor stock levels and product placement in real-time, improving accuracy and shelf management efficiency. Inventory robots navigate store aisles autonomously to scan shelves, identify out-of-stock items, and collect data on product availability, reducing human labor and errors. Explore how these innovative retail technologies can transform inventory management and enhance customer experience.

Why it is important

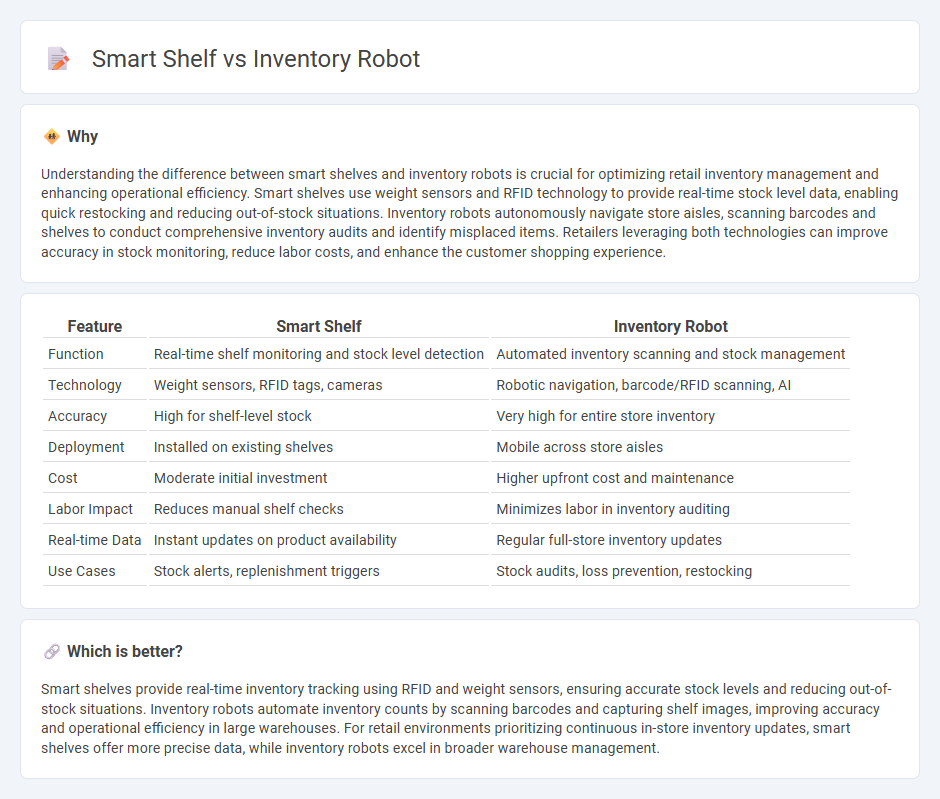

Understanding the difference between smart shelves and inventory robots is crucial for optimizing retail inventory management and enhancing operational efficiency. Smart shelves use weight sensors and RFID technology to provide real-time stock level data, enabling quick restocking and reducing out-of-stock situations. Inventory robots autonomously navigate store aisles, scanning barcodes and shelves to conduct comprehensive inventory audits and identify misplaced items. Retailers leveraging both technologies can improve accuracy in stock monitoring, reduce labor costs, and enhance the customer shopping experience.

Comparison Table

| Feature | Smart Shelf | Inventory Robot |

|---|---|---|

| Function | Real-time shelf monitoring and stock level detection | Automated inventory scanning and stock management |

| Technology | Weight sensors, RFID tags, cameras | Robotic navigation, barcode/RFID scanning, AI |

| Accuracy | High for shelf-level stock | Very high for entire store inventory |

| Deployment | Installed on existing shelves | Mobile across store aisles |

| Cost | Moderate initial investment | Higher upfront cost and maintenance |

| Labor Impact | Reduces manual shelf checks | Minimizes labor in inventory auditing |

| Real-time Data | Instant updates on product availability | Regular full-store inventory updates |

| Use Cases | Stock alerts, replenishment triggers | Stock audits, loss prevention, restocking |

Which is better?

Smart shelves provide real-time inventory tracking using RFID and weight sensors, ensuring accurate stock levels and reducing out-of-stock situations. Inventory robots automate inventory counts by scanning barcodes and capturing shelf images, improving accuracy and operational efficiency in large warehouses. For retail environments prioritizing continuous in-store inventory updates, smart shelves offer more precise data, while inventory robots excel in broader warehouse management.

Connection

Smart shelves and inventory robots are interconnected through real-time data synchronization that enhances stock management accuracy and efficiency in retail environments. Smart shelves use RFID tags and weight sensors to detect product levels, while inventory robots employ computer vision and AI algorithms to scan shelves and update inventory records dynamically. This integration minimizes stockouts, streamlines replenishment processes, and optimizes supply chain operations for retailers.

Key Terms

Stock Auditing

Inventory robots utilize advanced sensors and AI to conduct real-time stock auditing by scanning barcodes and RFID tags, ensuring precise inventory counts and reducing human error. Smart shelves integrate weight sensors and digital displays to automatically monitor stock levels and trigger alerts for replenishment, optimizing shelf management efficiency. Explore the differences further to determine which technology best enhances your stock auditing process.

Real-time Monitoring

Inventory robots provide real-time monitoring by autonomously navigating warehouse aisles to scan and update stock levels with high accuracy, reducing human error and labor costs. Smart shelves use embedded sensors to continuously track product movement and stock status, offering instant alerts for low inventory or misplaced items. Discover how integrating these technologies can enhance supply chain efficiency and accuracy.

Loss Prevention

Inventory robots use advanced sensors and AI to scan products continuously, identifying discrepancies and potential theft in real time, enhancing loss prevention accuracy. Smart shelves integrate weight sensors and RFID technology to detect misplaced or missing items instantly, reducing shrinkage through automated alerts. Explore how combining these technologies can revolutionize your store's loss prevention strategy.

Source and External Links

Dexory | Inventory Warehouse Automation With AI-Powered Real - Dexory offers autonomous inventory scanning robots that digitize up to 10,000 pallet locations per hour to provide real-time visibility, catch inventory errors instantly, and optimize warehouse space and resource use with AI analytics.

Stockbot | RFID Autonomous Robot for Retail - StockBot is an autonomous robot using RFID technology designed for accurate retail stock tracking and easy integration into any store layout to streamline inventory management.

Tally - Simbe Robotics - Tally is an autonomous shelf-scanning robot for retail that detects out-of-stocks, pricing errors, and inventory discrepancies with 99% accuracy, enabling near real-time insights and operational efficiency for stores.

dowidth.com

dowidth.com