Smart shelf technology uses sensors and RFID tags to provide real-time inventory tracking and product visibility on store shelves, enhancing customer experience and reducing stockouts. Automated replenishment leverages data analytics and AI algorithms to predict demand and streamline restocking processes, minimizing human error and optimizing inventory levels. Explore how these innovations are transforming retail efficiency and customer satisfaction.

Why it is important

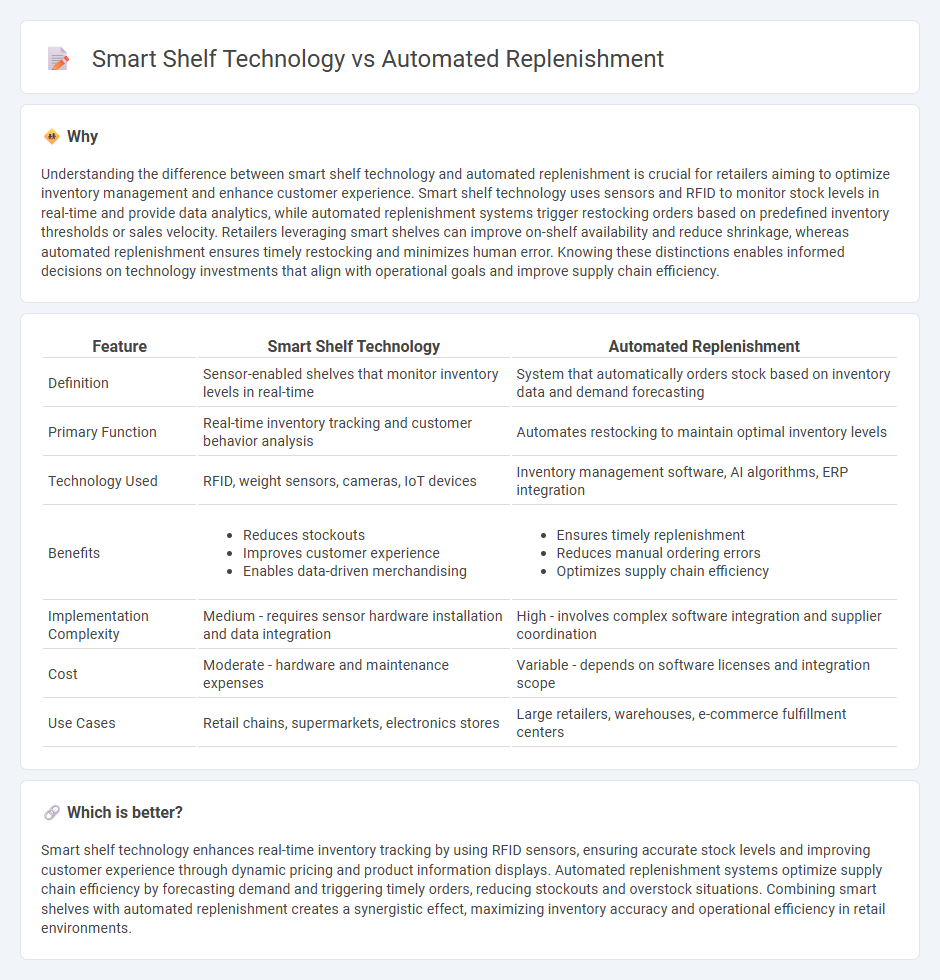

Understanding the difference between smart shelf technology and automated replenishment is crucial for retailers aiming to optimize inventory management and enhance customer experience. Smart shelf technology uses sensors and RFID to monitor stock levels in real-time and provide data analytics, while automated replenishment systems trigger restocking orders based on predefined inventory thresholds or sales velocity. Retailers leveraging smart shelves can improve on-shelf availability and reduce shrinkage, whereas automated replenishment ensures timely restocking and minimizes human error. Knowing these distinctions enables informed decisions on technology investments that align with operational goals and improve supply chain efficiency.

Comparison Table

| Feature | Smart Shelf Technology | Automated Replenishment |

|---|---|---|

| Definition | Sensor-enabled shelves that monitor inventory levels in real-time | System that automatically orders stock based on inventory data and demand forecasting |

| Primary Function | Real-time inventory tracking and customer behavior analysis | Automates restocking to maintain optimal inventory levels |

| Technology Used | RFID, weight sensors, cameras, IoT devices | Inventory management software, AI algorithms, ERP integration |

| Benefits |

|

|

| Implementation Complexity | Medium - requires sensor hardware installation and data integration | High - involves complex software integration and supplier coordination |

| Cost | Moderate - hardware and maintenance expenses | Variable - depends on software licenses and integration scope |

| Use Cases | Retail chains, supermarkets, electronics stores | Large retailers, warehouses, e-commerce fulfillment centers |

Which is better?

Smart shelf technology enhances real-time inventory tracking by using RFID sensors, ensuring accurate stock levels and improving customer experience through dynamic pricing and product information displays. Automated replenishment systems optimize supply chain efficiency by forecasting demand and triggering timely orders, reducing stockouts and overstock situations. Combining smart shelves with automated replenishment creates a synergistic effect, maximizing inventory accuracy and operational efficiency in retail environments.

Connection

Smart shelf technology integrates sensors and RFID to monitor inventory levels in real-time, enabling automated replenishment systems to trigger restocking orders immediately when stock dips below predefined thresholds. This seamless connection minimizes out-of-stock situations, enhances supply chain efficiency, and ensures optimal product availability. Retailers benefit from reduced manual inventory checks, lower carrying costs, and improved customer satisfaction through always-available merchandise.

Key Terms

Inventory Management

Automated replenishment systems use real-time sales data and predictive analytics to maintain optimal inventory levels, reducing stockouts and excess inventory costs. Smart shelf technology integrates RFID sensors and weight detectors to provide continuous, accurate inventory tracking and alerts for immediate restocking needs. Explore how these advanced inventory management solutions can enhance efficiency and profitability.

Real-time Data

Automated replenishment systems leverage real-time data analytics to forecast inventory needs and trigger timely restocking, reducing stockouts and excess inventory. Smart shelf technology employs sensors and RFID tags to monitor product levels continuously, providing instant visibility into shelf status and consumer interactions. Explore how integrating these technologies can optimize inventory management and enhance supply chain efficiency.

Demand Forecasting

Automated replenishment systems utilize advanced algorithms to analyze historical sales data and real-time inventory levels, enabling precise demand forecasting that reduces stockouts and overstock situations. Smart shelf technology integrates IoT sensors and AI to monitor product movement and shelf conditions, offering dynamic demand insights and enhancing inventory accuracy. Discover more about how these technologies revolutionize demand forecasting and optimize retail operations.

Source and External Links

Automatic Replenishment: Everything You Need to Know - Automated replenishment is a computerized system that monitors inventory levels and automatically triggers orders to restock products when they fall below set reorder thresholds, using real-time data and technology like barcode scanners or RFID tags to optimize inventory management and reduce manual intervention.

What is Automatic Replenishment? 8 Advantages & How- ... - Automatic replenishment maintains optimal stock levels by automatically reordering products when inventory drops below minimum thresholds, enhancing efficiency, reducing overstocking, and ensuring consistent supply to meet customer demand.

Automated Replenishment Software - Powered by AI and advanced algorithms, automated replenishment software precisely forecasts demand and generates time-phased replenishment plans, enabling businesses to maintain ideal inventory levels, optimize supply chains, and maximize sales by responding to changing demand signals.

dowidth.com

dowidth.com