Predictive fleet maintenance leverages real-time data and analytics to forecast vehicle repairs, minimizing downtime and operational costs for logistics companies. Reverse logistics focuses on the efficient return, recycling, and disposal of products, enhancing sustainability and reducing waste in the supply chain. Explore how integrating predictive maintenance with reverse logistics can optimize fleet performance and environmental impact.

Why it is important

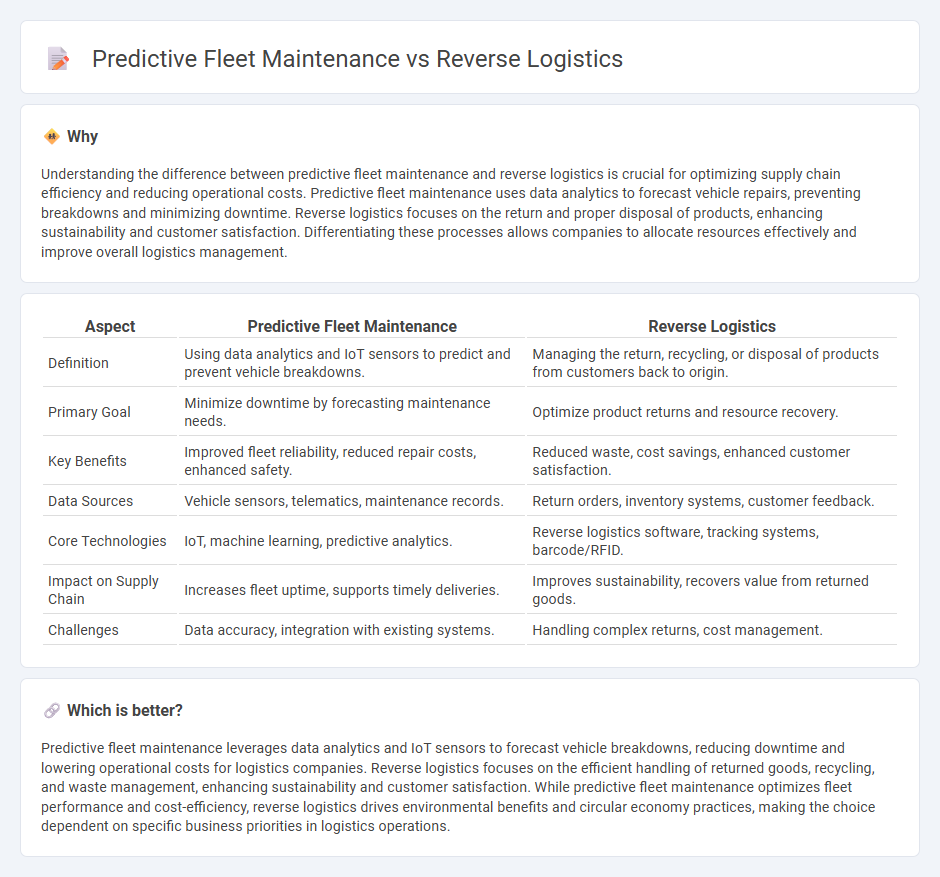

Understanding the difference between predictive fleet maintenance and reverse logistics is crucial for optimizing supply chain efficiency and reducing operational costs. Predictive fleet maintenance uses data analytics to forecast vehicle repairs, preventing breakdowns and minimizing downtime. Reverse logistics focuses on the return and proper disposal of products, enhancing sustainability and customer satisfaction. Differentiating these processes allows companies to allocate resources effectively and improve overall logistics management.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Reverse Logistics |

|---|---|---|

| Definition | Using data analytics and IoT sensors to predict and prevent vehicle breakdowns. | Managing the return, recycling, or disposal of products from customers back to origin. |

| Primary Goal | Minimize downtime by forecasting maintenance needs. | Optimize product returns and resource recovery. |

| Key Benefits | Improved fleet reliability, reduced repair costs, enhanced safety. | Reduced waste, cost savings, enhanced customer satisfaction. |

| Data Sources | Vehicle sensors, telematics, maintenance records. | Return orders, inventory systems, customer feedback. |

| Core Technologies | IoT, machine learning, predictive analytics. | Reverse logistics software, tracking systems, barcode/RFID. |

| Impact on Supply Chain | Increases fleet uptime, supports timely deliveries. | Improves sustainability, recovers value from returned goods. |

| Challenges | Data accuracy, integration with existing systems. | Handling complex returns, cost management. |

Which is better?

Predictive fleet maintenance leverages data analytics and IoT sensors to forecast vehicle breakdowns, reducing downtime and lowering operational costs for logistics companies. Reverse logistics focuses on the efficient handling of returned goods, recycling, and waste management, enhancing sustainability and customer satisfaction. While predictive fleet maintenance optimizes fleet performance and cost-efficiency, reverse logistics drives environmental benefits and circular economy practices, making the choice dependent on specific business priorities in logistics operations.

Connection

Predictive fleet maintenance leverages IoT sensors and machine learning algorithms to anticipate vehicle failures, optimizing repair schedules and minimizing downtime. This proactive approach directly supports reverse logistics by ensuring efficient return, repair, and refurbishment of assets, reducing costs and environmental impact. Integrating predictive maintenance data streamlines reverse logistics workflows, enhancing overall supply chain sustainability.

Key Terms

**Reverse Logistics:**

Reverse logistics optimizes the process of returning goods from customers back to manufacturers or distributors, reducing waste and recovering value through refurbishment or recycling. Key components include efficient return management, inventory control, and sustainable disposal methods, driving cost savings and environmental benefits. Explore the transformative impact of reverse logistics on supply chain efficiency and sustainability.

Returns Management

Reverse logistics centers on the efficient handling, transportation, and processing of returned products to maximize recovery and minimize waste. Predictive fleet maintenance utilizes IoT sensors and data analytics to anticipate vehicle issues, reducing downtime and optimizing logistics operations. Discover how integrating these strategies can enhance returns management and operational efficiency.

Refurbishment

Reverse logistics emphasizes the efficient return, refurbishment, and resale of products, reducing waste and extending product lifecycle. Predictive fleet maintenance uses data analytics and IoT sensors to forecast and prevent vehicle breakdowns, optimizing fleet performance and minimizing downtime. Explore how integrating refurbishment processes with predictive maintenance enhances operational efficiency and sustainability.

Source and External Links

What is Reverse Logistics? - c3controls - Reverse logistics is the cost-effective process of moving goods from the final customer back to the manufacturer or distributor for return, repair, remanufacture, recycling, or disposal, contributing to leaner, more sustainable supply chains.

A Guide to Reverse Logistics: How It Works, Types and Strategies - Reverse logistics involves managing returns and surplus goods from customers back to sellers or manufacturers, with industry-specific processes such as reusing containers in beverage production or recycling materials in construction.

Reverse logistics - Wikipedia - Reverse logistics encompasses all operations related to moving products and materials upstream in the supply chain for value capture or disposal, including remanufacturing and refurbishing, with a global market expected to grow significantly in the coming years.

dowidth.com

dowidth.com