Yard management focuses on optimizing the movement, storage, and inventory of materials within a facility's yard to enhance operational efficiency and reduce turnaround time. Returns management handles the process of receiving, inspecting, and refurbishing or disposing of returned goods, crucial for customer satisfaction and cost control in reverse logistics. Explore in-depth insights on how strategic yard and returns management improve overall supply chain performance.

Why it is important

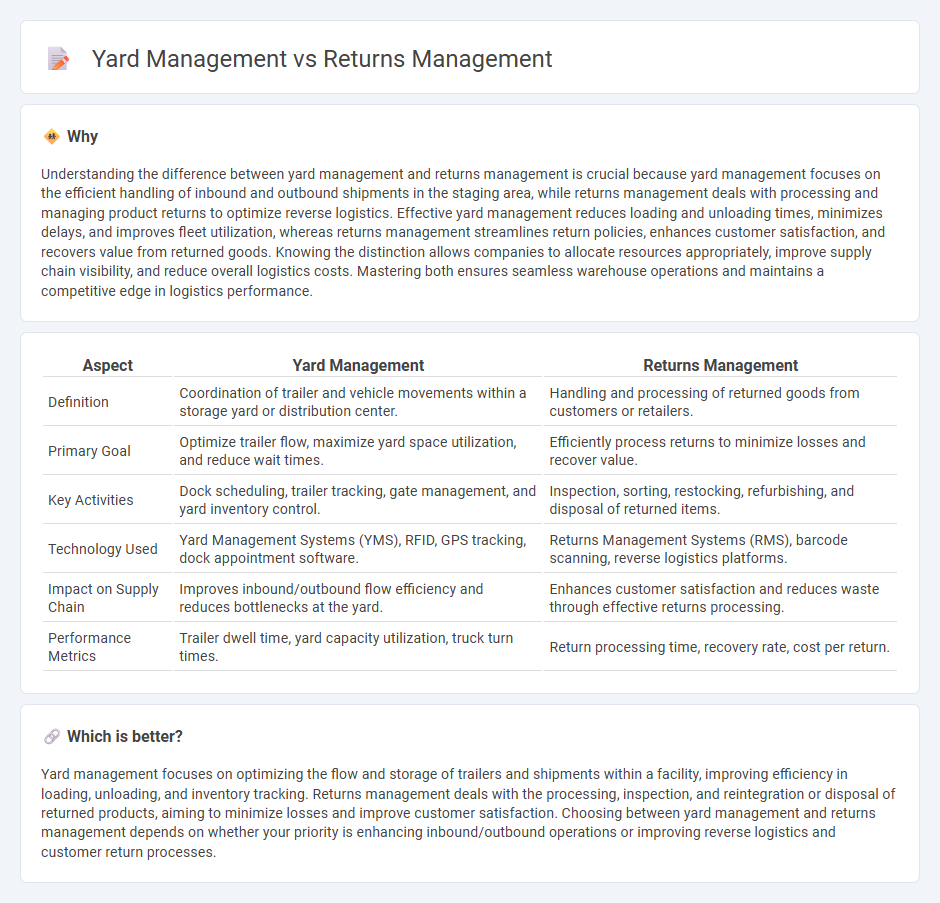

Understanding the difference between yard management and returns management is crucial because yard management focuses on the efficient handling of inbound and outbound shipments in the staging area, while returns management deals with processing and managing product returns to optimize reverse logistics. Effective yard management reduces loading and unloading times, minimizes delays, and improves fleet utilization, whereas returns management streamlines return policies, enhances customer satisfaction, and recovers value from returned goods. Knowing the distinction allows companies to allocate resources appropriately, improve supply chain visibility, and reduce overall logistics costs. Mastering both ensures seamless warehouse operations and maintains a competitive edge in logistics performance.

Comparison Table

| Aspect | Yard Management | Returns Management |

|---|---|---|

| Definition | Coordination of trailer and vehicle movements within a storage yard or distribution center. | Handling and processing of returned goods from customers or retailers. |

| Primary Goal | Optimize trailer flow, maximize yard space utilization, and reduce wait times. | Efficiently process returns to minimize losses and recover value. |

| Key Activities | Dock scheduling, trailer tracking, gate management, and yard inventory control. | Inspection, sorting, restocking, refurbishing, and disposal of returned items. |

| Technology Used | Yard Management Systems (YMS), RFID, GPS tracking, dock appointment software. | Returns Management Systems (RMS), barcode scanning, reverse logistics platforms. |

| Impact on Supply Chain | Improves inbound/outbound flow efficiency and reduces bottlenecks at the yard. | Enhances customer satisfaction and reduces waste through effective returns processing. |

| Performance Metrics | Trailer dwell time, yard capacity utilization, truck turn times. | Return processing time, recovery rate, cost per return. |

Which is better?

Yard management focuses on optimizing the flow and storage of trailers and shipments within a facility, improving efficiency in loading, unloading, and inventory tracking. Returns management deals with the processing, inspection, and reintegration or disposal of returned products, aiming to minimize losses and improve customer satisfaction. Choosing between yard management and returns management depends on whether your priority is enhancing inbound/outbound operations or improving reverse logistics and customer return processes.

Connection

Yard management optimizes the flow and storage of incoming and outgoing goods, directly impacting the efficiency of returns management by streamlining the receipt and inspection of returned items. Effective coordination between yard operations and returns processing reduces delays, minimizes handling costs, and improves inventory accuracy. Integrating yard management systems with returns management ensures timely reverse logistics, enhancing overall supply chain performance.

Key Terms

**Returns Management:**

Returns management involves overseeing the process of handling returned products efficiently to minimize costs and improve customer satisfaction. Key activities include inspection, sorting, refurbishing, restocking, or disposing of items, supported by software that tracks returns data and automates workflows. Discover how effective returns management can enhance inventory control and boost profitability.

Reverse Logistics

Returns management centers on efficiently processing product returns to minimize costs and enhance customer satisfaction within reverse logistics frameworks. Yard management optimizes the movement, storage, and staging of vehicles and goods in distribution centers, indirectly supporting reverse logistics by ensuring smooth flow of returned items. Explore how integrating returns and yard management strategies drives operational excellence in reverse logistics.

RMA (Return Merchandise Authorization)

Returns management centers on processing RMA requests to authorize product returns, ensuring efficient handling of defective or unwanted merchandise and customer satisfaction. Yard management optimizes the movement and storage of goods within the shipping yard, coordinating incoming and outgoing shipments to minimize delays and maximize yard utilization. Explore detailed strategies to improve your RMA process and streamline yard operations for enhanced supply chain performance.

Source and External Links

Best practices for efficient returns management - Sage - Returns management is the process of overseeing returned products to ensure a seamless experience for customers and the business, impacting customer retention, operational efficiency, and profitability, with key steps including return authorization and automation to minimize fraud and boost satisfaction.

How to Streamline Returns Management & Reduce Costs - Returns management involves managing customer return requests through to restocking returned products, combining customer support, logistics, and inventory management to reduce losses and improve business outcomes, especially critical in e-commerce where return rates can reach 20% or more.

Returns Management Software (RMS) | Blue Yonder - Blue Yonder offers integrated returns management solutions that optimize the entire returns journey through data-driven workflows and customer self-service features, reducing time, costs, and improving customer satisfaction across millions of returns handled.

dowidth.com

dowidth.com